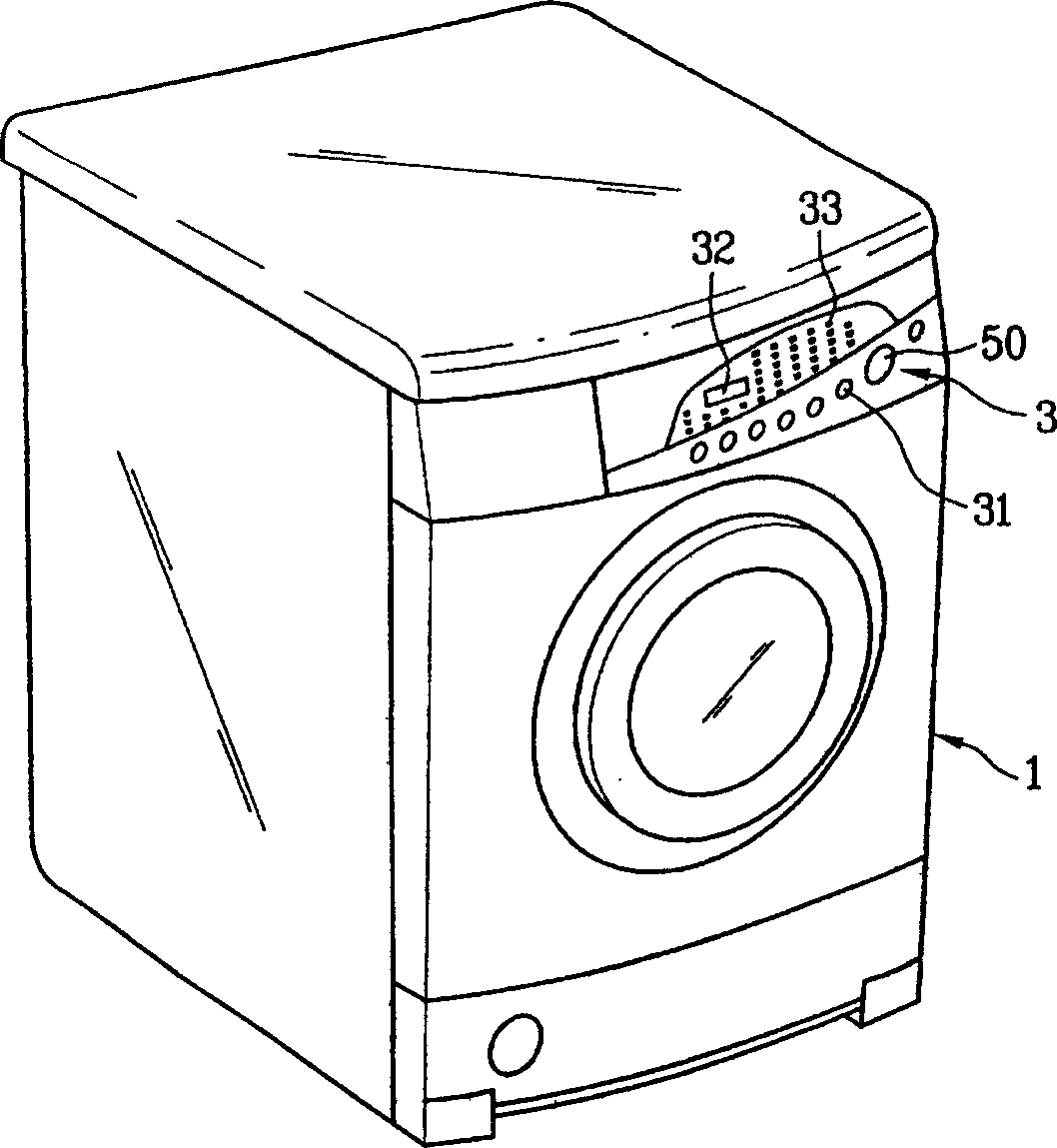

Bulb rack structure of rotary press button module of drum washing machine

A technology of a drum washing machine and a bracket structure, which is applied to other washing machines, washing devices, textiles, and papermaking, and can solve the problems of not being able to prevent damage to the rotary switch 5 and not being able to protect the rotary switch, so as to prevent left and right shaking, prevent damage, The effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

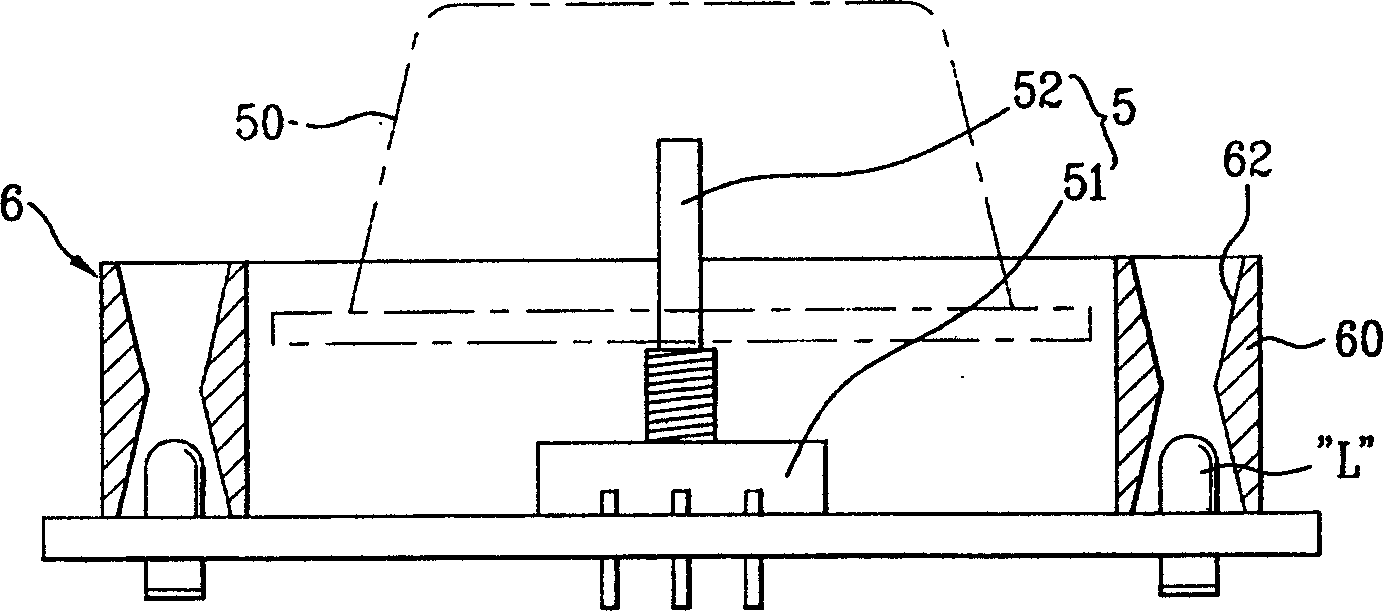

[0028] Below, refer to the attached Figure 5 , Figure 6 And the embodiment describes the present invention in detail. In the following description, the same reference numerals are used for the same parts as in the prior art.

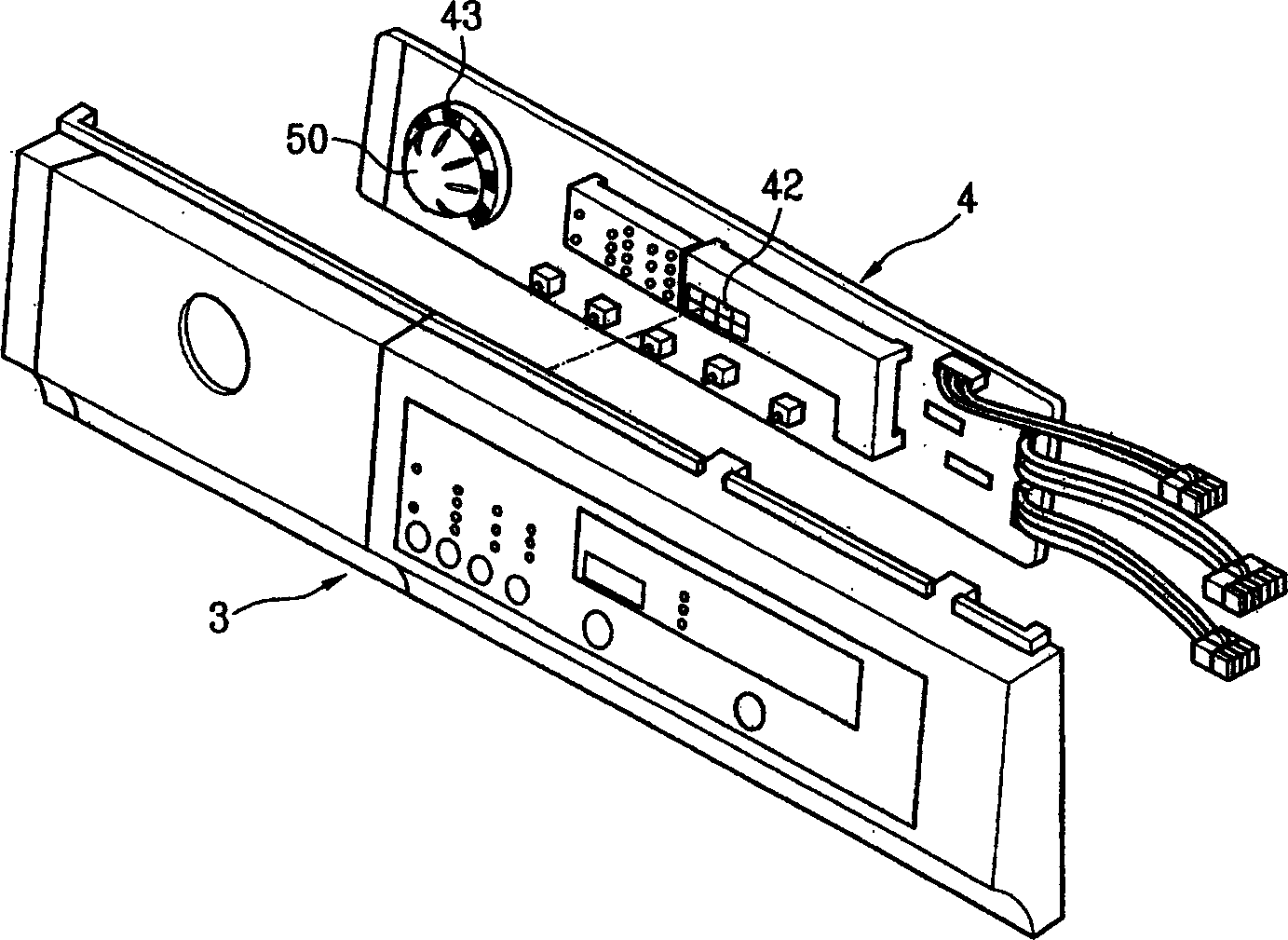

[0029] Such as Figure 5 , Figure 6 As shown, the light bulb support structure of the rotary button assembly of the drum washing machine includes a rotary switch composed of an encoder fixed on the circuit board and a supporting encoder shaft, a rotation selection button combined with the encoder shaft of the rotary switch, and a circle rotating The button is fixed on the circuit board and the main frame is a ring-shaped light bulb holder. The light bulb holder structure is also provided with shaft support ribs 61 and button support ribs 63. The shaft support ribs 61 are arranged in the main frame 60 of the light bulb holder 6. The side and the outer side supporting the encoder shaft 52. The button supporting rib 63 is provided on the upper surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap