Vaporizer for CVD, solution voporizing CVD device and voporization method for CVD

A vaporizer and gasification technology, applied in chemical instruments and methods, gaseous chemical plating, electrical components, etc., can solve problems such as heightening, blocked piping or flow meter blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

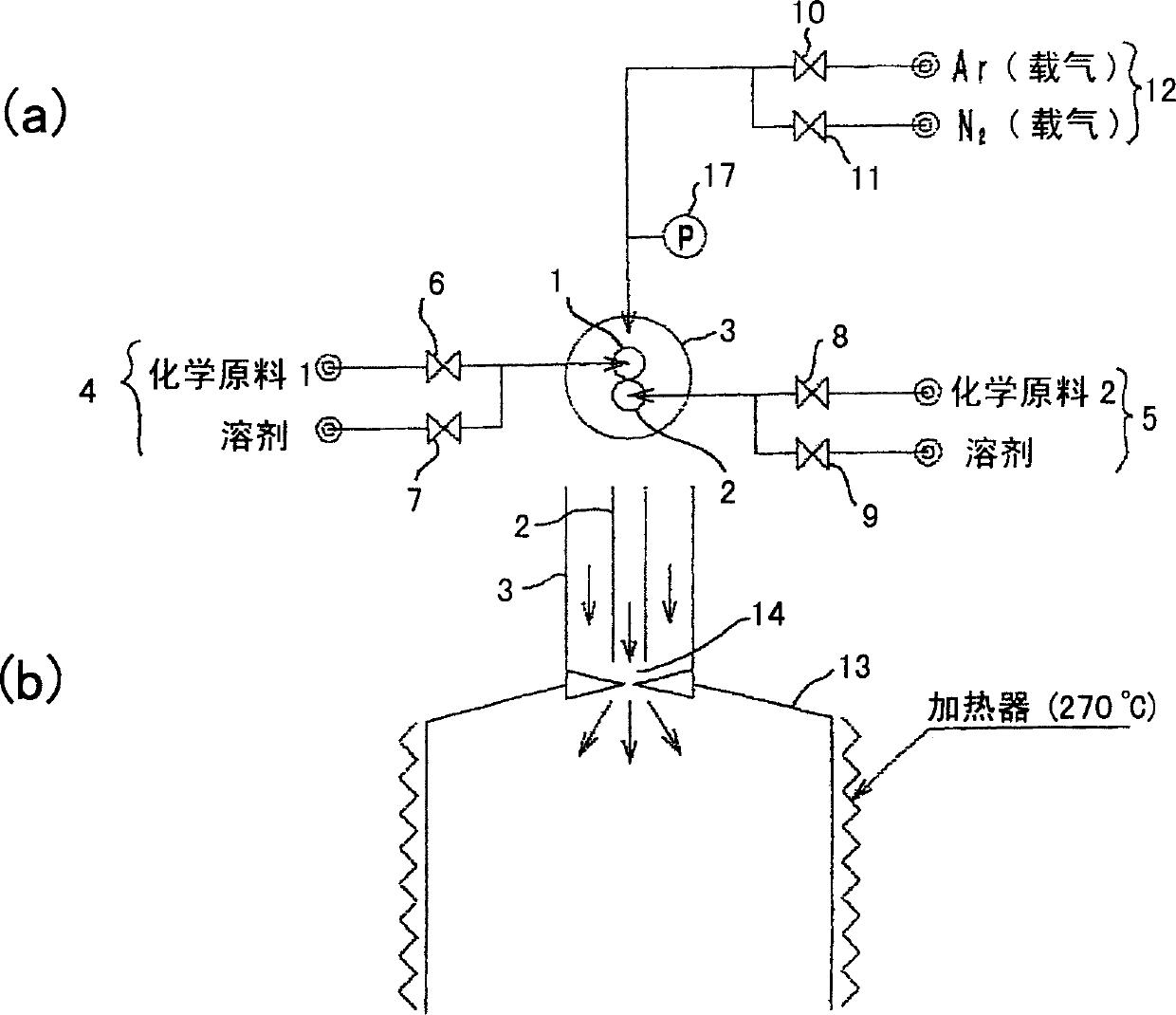

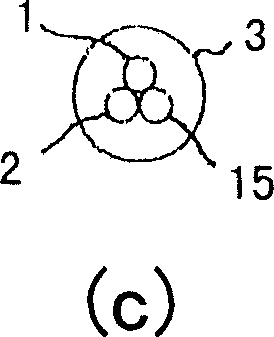

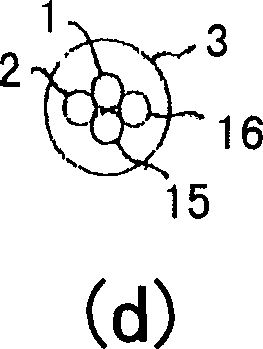

Method used

Image

Examples

Embodiment Construction

[0148] Examples are described below.

[0149] 3 to 8 show the results of monitoring the pressure of the carrier gas.

[0150] As shown in FIG. 3 , at monitoring point 80, the chemical raw material begins to flow into the gasification pipe 13, and then the pressure of the carrier gas rises. At point 420, the pressure of the carrier gas of BiMMP rises until 220kPa (about 2.2 barometric pressure). At this time, BiMMP (0.2 ccm) was stopped, and the cleaning solution ECH (0.5 ccm) was flowed in. At this time, the pressure of the carrier gas drops rapidly, and reaches a stable 440 points of 120kPa. This decrease in carrier gas pressure indicates that the BiMMP adhering to the front end (pore) of the nebulizer has been washed and removed.

[0151] The same is true for Figs. 4 to 6, and the adhesion phenomenon at the tip of the nebulizer can be seen with good reproducibility. This phenomenon is not limited to the use of Sr[Ta(OEt) 5 (OC 2 h4 OMe)] 2 with Bi(MMP) 3 This phenomen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com