Pretensioner mechanism

A pre-tightening mechanism and component technology, which is applied to belt tighteners, energy-absorbing devices, seat belts in vehicles, etc., can solve the problem of increased restraint of seat belts on passengers, and achieve the effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

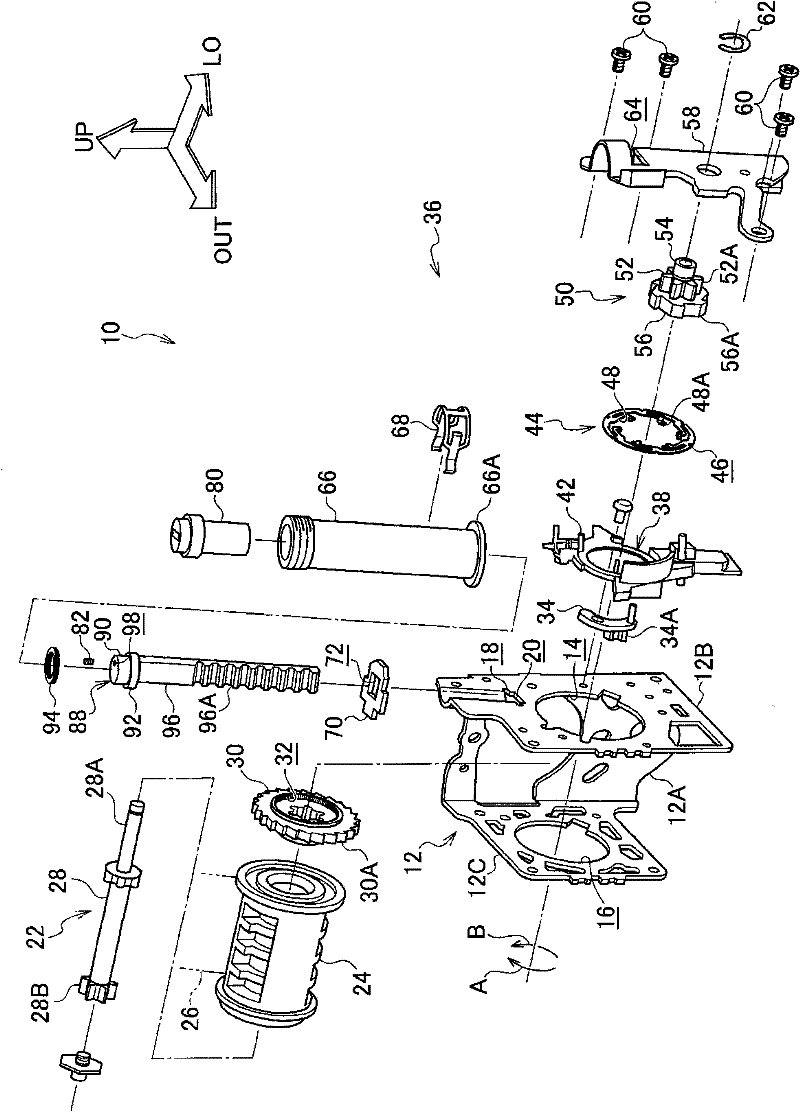

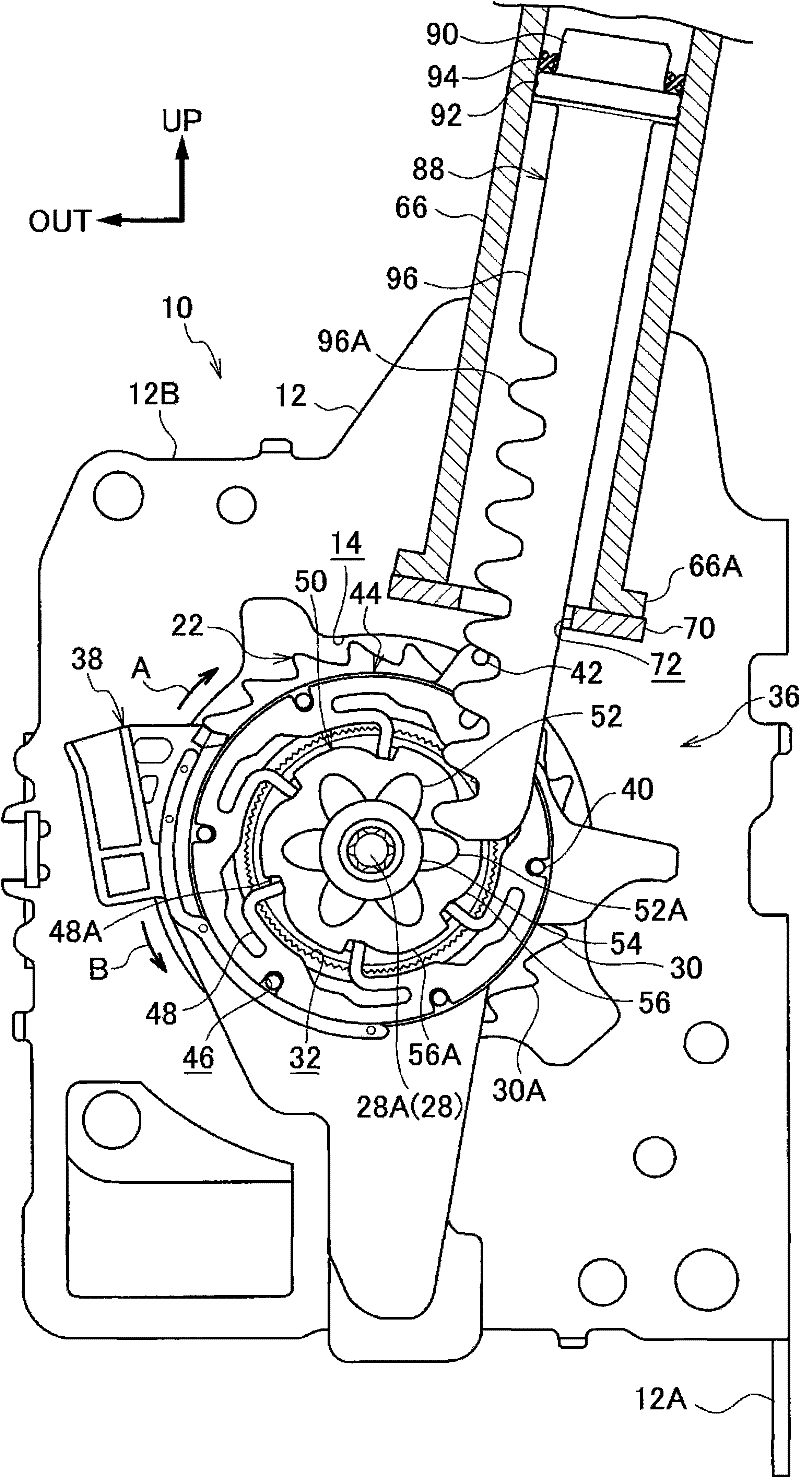

[0029] figure 2 The figure shows the seat belt take-up mechanism 10 to which the pretensioning mechanism 36 according to the first embodiment of the present invention is applied in an exploded perspective view viewed from the outside in the vehicle width direction and from one side in the vehicle front-rear direction, image 3 FIG. 3 shows the seat belt take-up device 10 in a side view viewed from one side in the front-rear direction of the vehicle. In addition, in the drawings, the outer side in the vehicle width direction is indicated by the arrow OUT, the one side in the front and rear direction of the vehicle is indicated by the arrow LO, and the upward direction is indicated by the arrow UP.

[0030] Such as figure 2 as well as image 3 As shown, in the seat belt take-up device 10 according to this embodiment, a plate-shaped frame 12 having a U-shaped cross section as a main body member is provided, and the frame 12 is provided with: The foot plate 12B on one side in...

no. 2 Embodiment approach

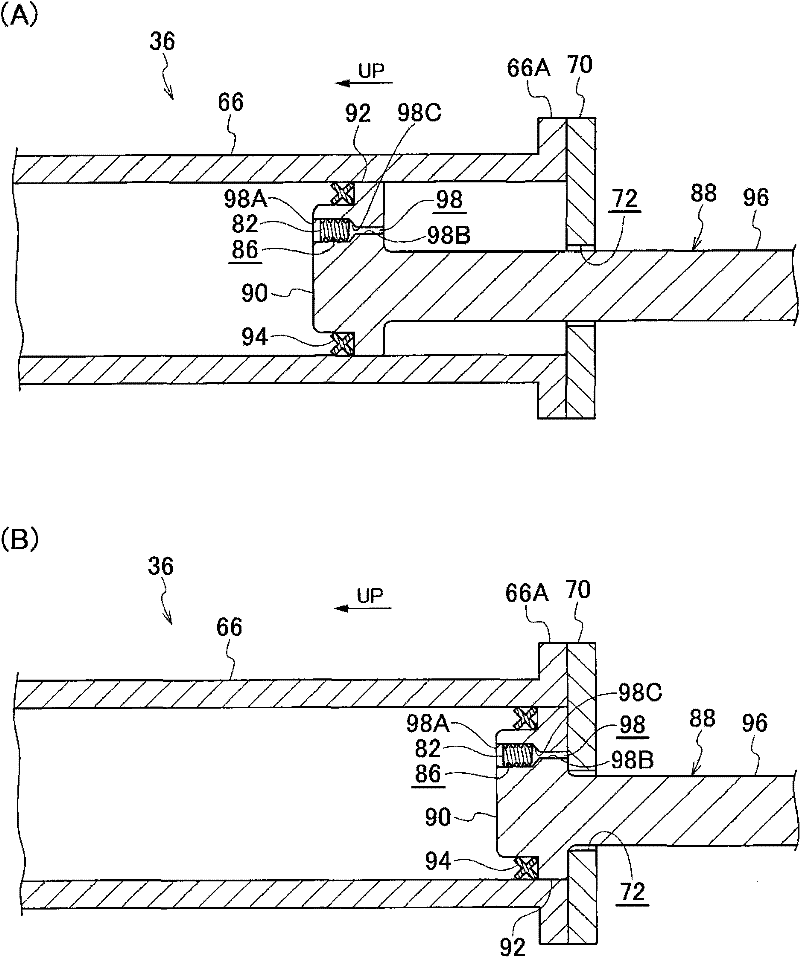

[0076] Figure 6 (A) and (B) are sectional views of main parts of the pretensioner mechanism 100 according to the second embodiment of the present invention.

[0077] The structure of the preload mechanism 100 according to this embodiment is basically the same as that of the above-mentioned first embodiment, but differs in the following points.

[0078] In the preload mechanism 100 according to this embodiment, the thread groove 86 is not formed on the peripheral surface of the closing member 82, but the thread groove 86 is formed on the peripheral surface of the large-diameter portion 98A of the communication hole 98, and the thread groove 86 has a spiral shape. shape, is arranged so as to be inclined with respect to the axial direction of the communicating hole 98 (the axial direction of the closing member 82 ), and communicates with the upper side and the lower side of the closing member 82 . The cross-sectional area of the screw groove 86 is as small as possible within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com