Knitting method of five toe socks

A technology for five-toed socks and socks, which is used in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of many processes, unstable product quality, and many staffing, saving personnel and equipment, improving production efficiency and improving production efficiency. Economic benefits, the effect of solving the exposed thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with a preferred embodiment and accompanying drawing thereof, the present invention will be further described,

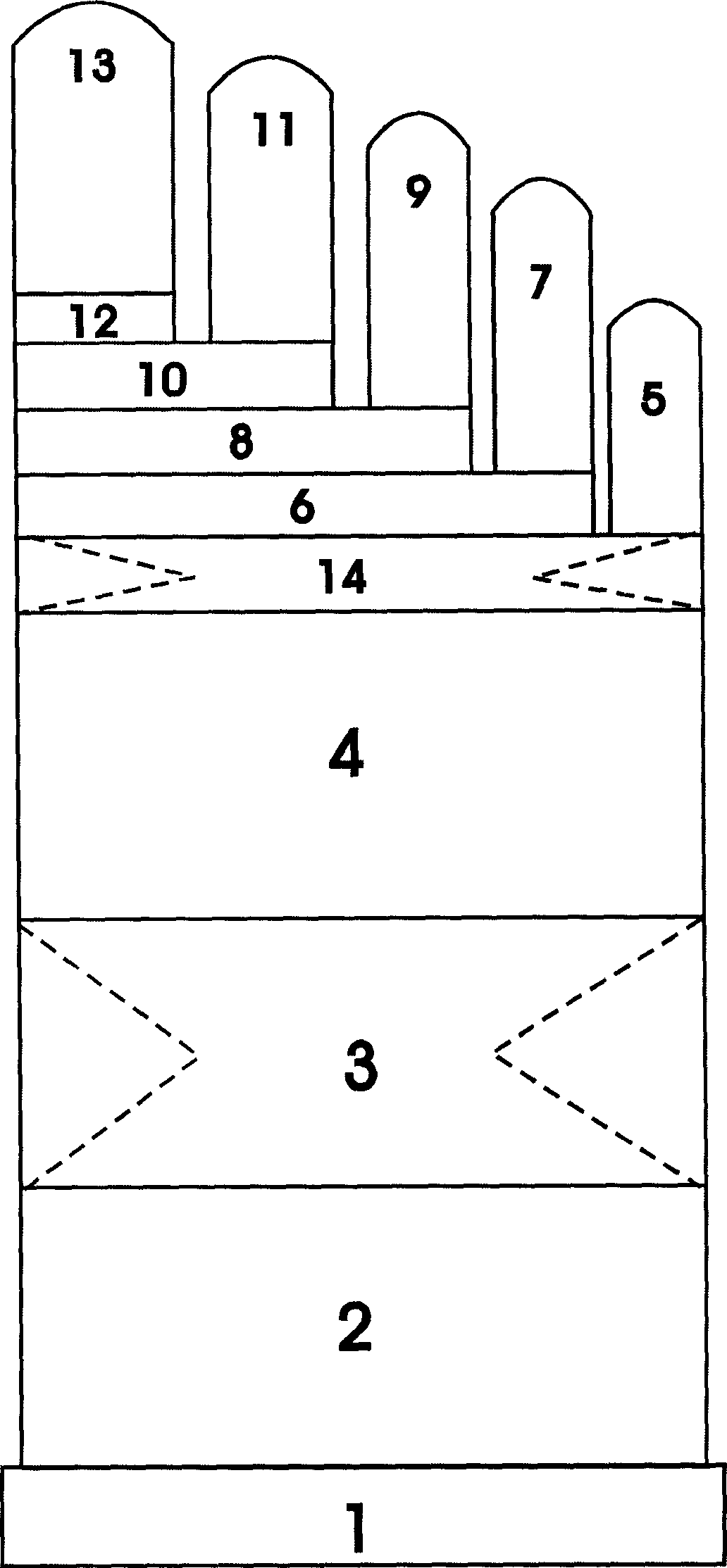

[0012] See attached image 3 As shown, the knitting process of the five-toed socks is all completed on the sock knitting machine. The specific steps are: first weave the cuff part 1 of the sock, and then weave the sock tube part 2, the heel part 3, the sole part 4, the little thumb 5 toes, 6 between the fourth toes, 7 ring toes, 8 between the third toes, 9 middle toes, 10 between the second toes, 11 index toes, 12 big toes, big toes Section 13, Sewn Section 14.

[0013] The embodiments described above are only preferred embodiments of the present invention, and are not intended to limit the scope of the present invention. Therefore, all equivalent changes made according to the shape, structure and principle of the present invention should be covered by the scope of the present invention. within the scope of protection.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap