Method for manufacturing microlens and apparatus for manufacturing the same

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing microlenses, can solve problems such as small degrees of freedom and difficulty in ensuring the adhesion between microlenses and substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each drawing used in the following description, in order to make each member a recognizable size, the scale of each member is appropriately changed.

[0023] [Manufacturing method of micro lens]

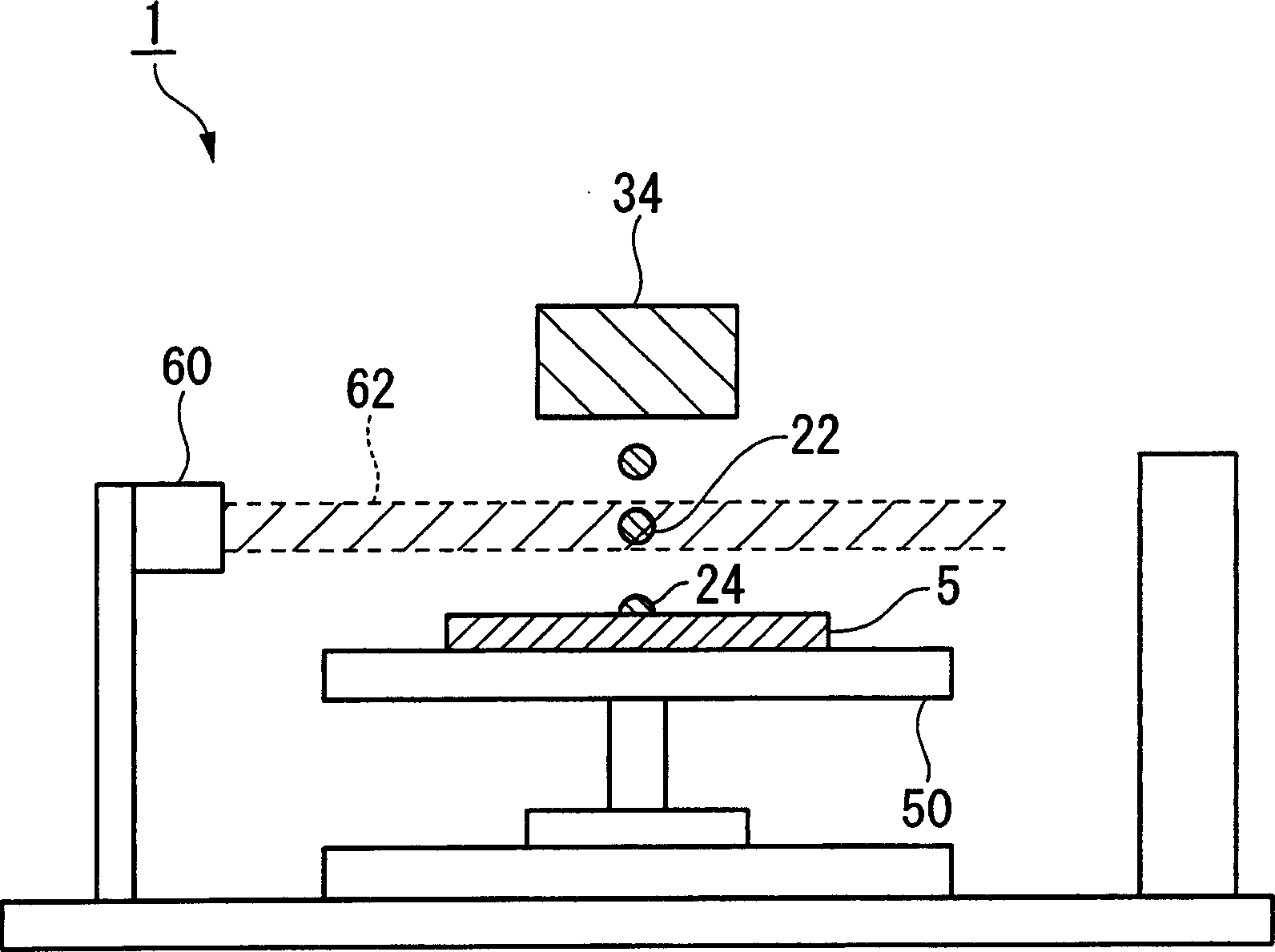

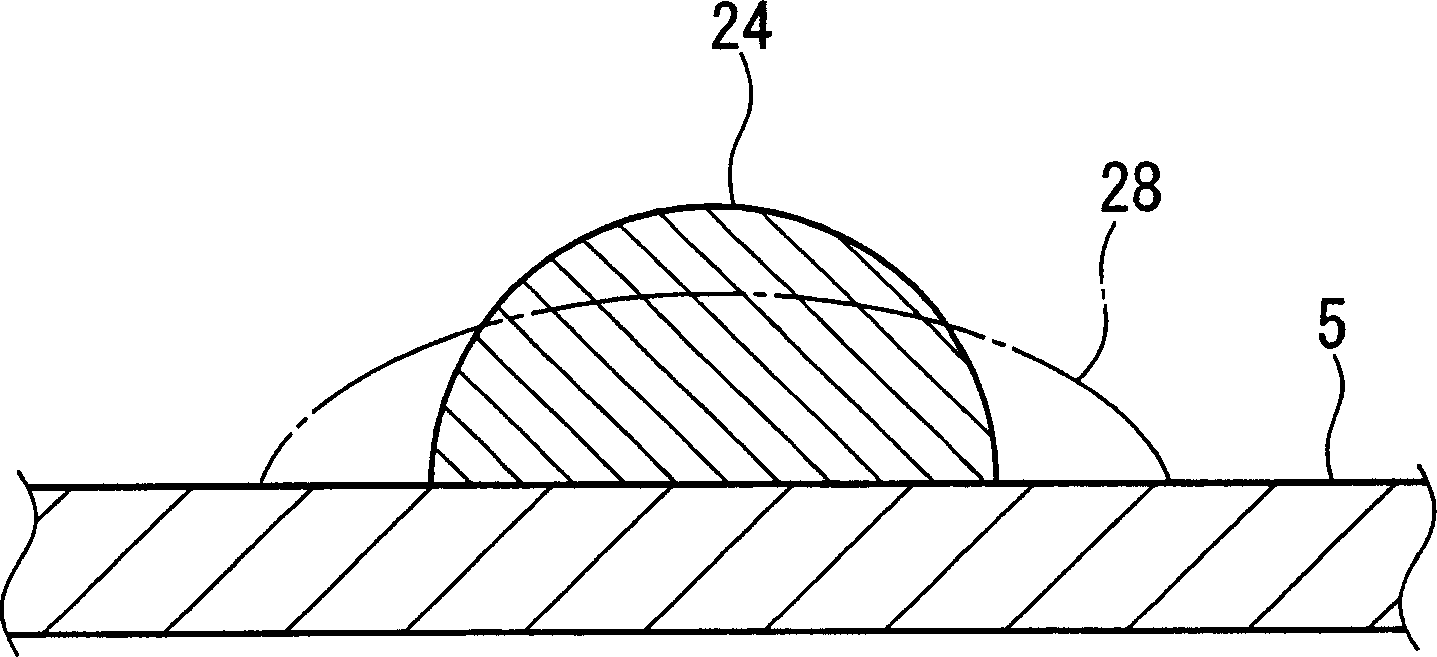

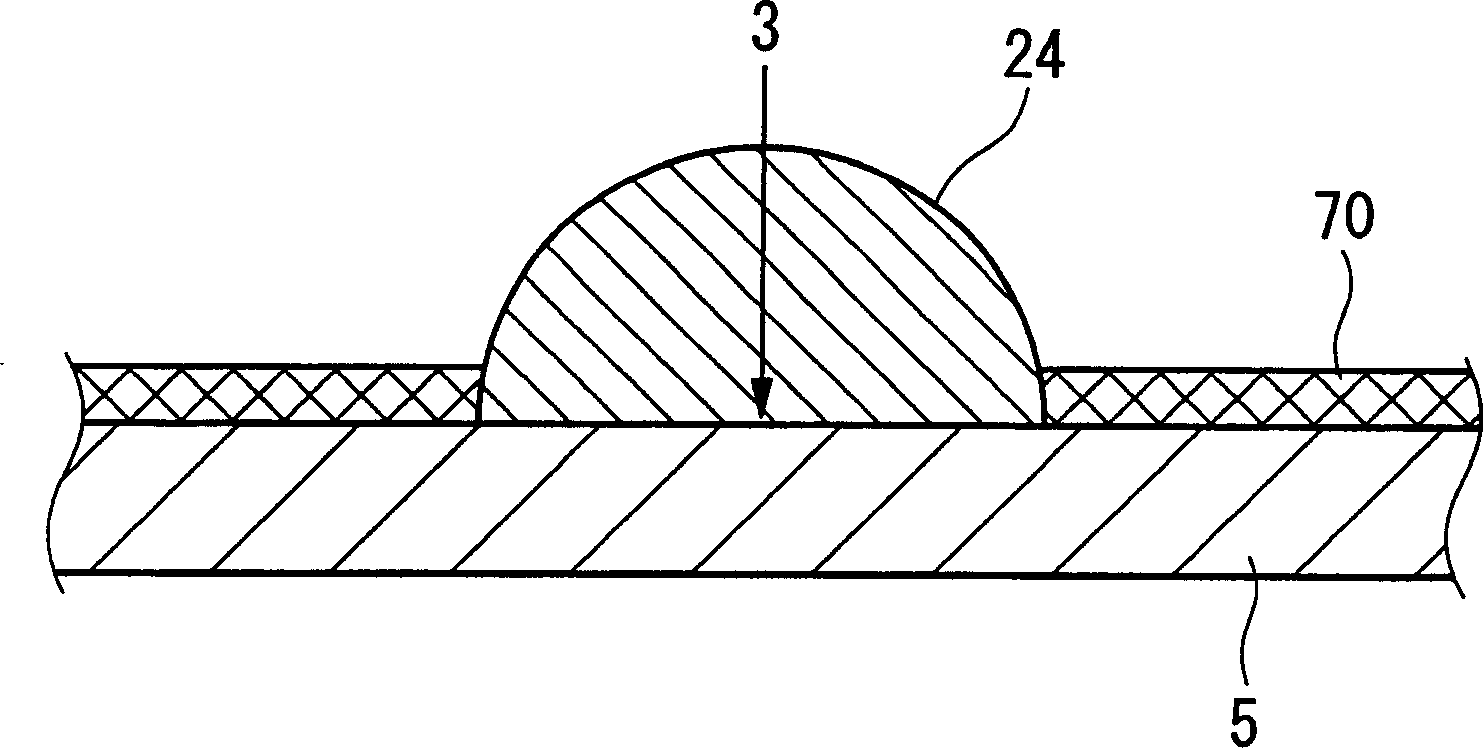

[0024] figure 1 It is a schematic diagram showing the manufacturing method of the microlens in this embodiment. The method of manufacturing a microlens of this embodiment is a method of manufacturing a microlens by ejecting a droplet 22 containing a constituent material of the microlens from a droplet ejection head 34 and landing on the substrate 5. After the droplet 22 is ejected Until just after the bounce, the ejected droplets 22 are irradiated with ultraviolet rays 62 at least once.

[0025] [Material of the micro lens]

[0026] As a constituent material (lens material) of the microlens, a translucent resin having ultraviolet curability is used. As the transluc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com