Hall linear displacement transducer without lead

A linear displacement, sensor technology, applied in the direction of using electric/magnetic devices to transmit sensing components, can solve the problems of measurement range influence, short service life, influence measurement accuracy, etc., to improve measurement accuracy, improve service life, increase The effect of a large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

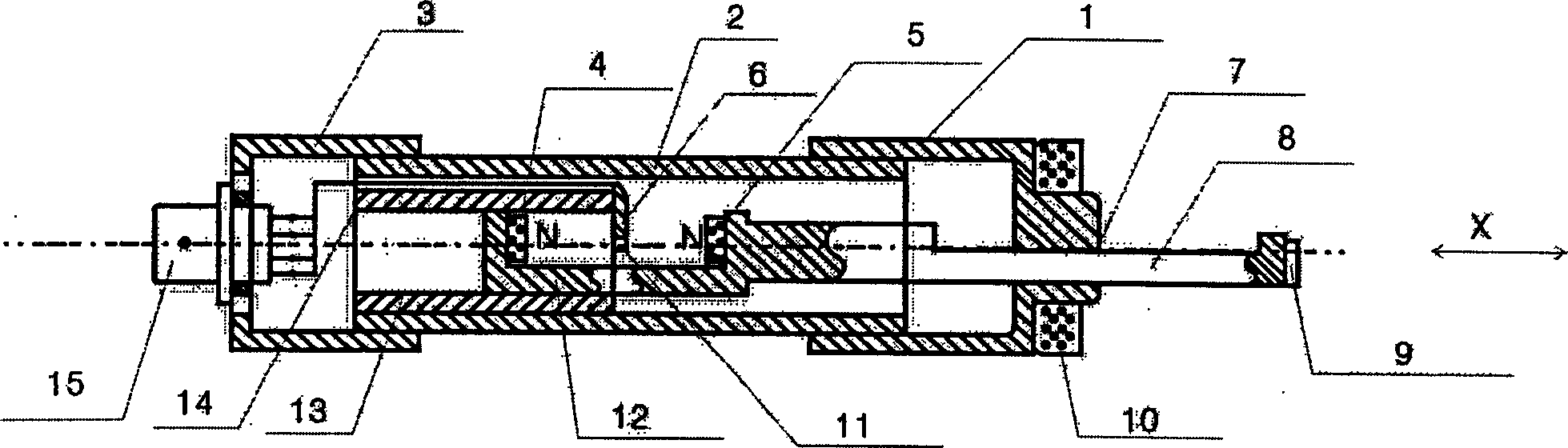

[0011] As shown in the accompanying drawings, the uninvolved Hall linear displacement sensor has a connected front end cover 1, an outer cover 2, and a rear end cover 3. An inner sleeve 13 is provided in the outer cover near the rear end cover, and the front end cover 1 is equipped with a measuring rod 8. , the surface of the measuring rod 8 is provided with an anti-rotation surface 7, the outer end of the measuring rod is provided with a permanent magnet 9, the inner end of the measuring rod is connected with a magnetic steel seat 12, and the magnetic steel seat 12 is provided with a first permanent magnet 4 and a second permanent magnet. The magnetic steel 5 and the first permanent magnetic steel 4 are in the inner sleeve, the end surface of the inner sleeve is provided with a printed board 6 and a Hall element 11, and the outer end of the rear end cover 3 is provided with a socket 15.

[0012] The length of interior cover 13 is the half of overcoat 2 lengths. The anti-rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com