Impedance type soil moisture sensor and making process thereof

A technology of soil moisture and production process, which is applied in the production process of impedance soil moisture sensor and the field of impedance soil moisture sensor, which can solve problems such as difficulty in adoption, large slope of the relationship curve between resistance and suction, and insufficient wide test range of the dry end. , to achieve the effect of a wide range of humidity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

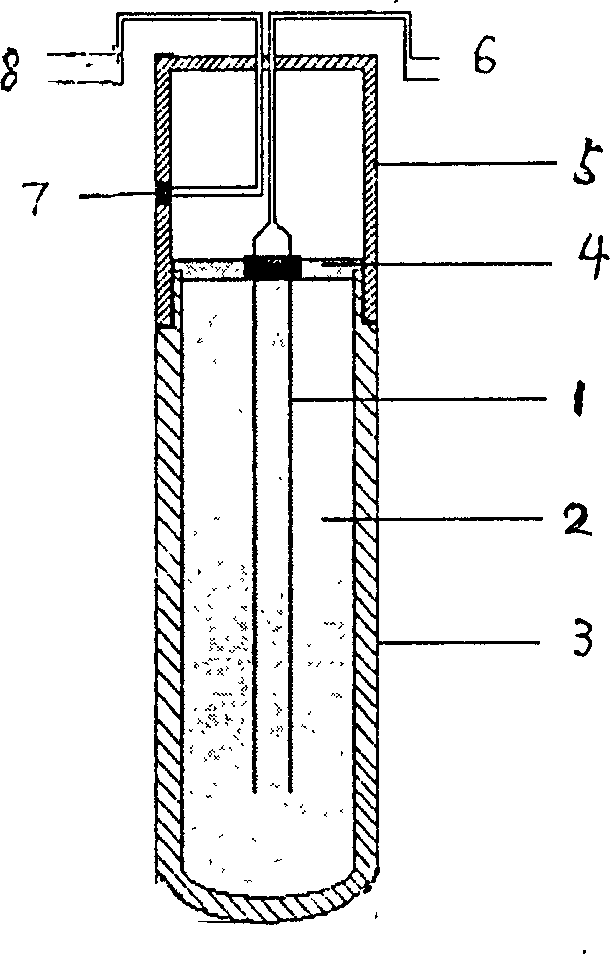

[0041] Embodiment 1, with reference to figure 1 : Impedance type soil moisture sensor, two parallel stainless steel electrodes 1 are placed in the resistance block and lead out the cable 6, the resistance block is made of filling material 2 filled in clay head 3, the composition of the filling material is: Contains SiO 2Mainly sandy loam and gypsum powder are mixed at a ratio of about 3:2 as the base material, and at the same time, artificial structure modifiers are added to the base material. A PVC pipe 5 is glued on the clay head 3 with epoxy resin 4, and a temperature sensor 7 is installed in the pipe, and its lead wire 8 is used to correct the change of the conductance value caused by the temperature change.

[0042] Specifically, the composition and manufacturing process of each part are as follows:

[0043] The material composition of the sensor:

[0044] The ideal resistance block should be a porous body with relatively uniform distribution of fine and small pores. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com