High-polymer resistance type thin film humidity-sensitive element with high water-proofing performance and producing method thereof

A technology of humidity sensor and resistive type, which is applied in the field of polymer resistive thin film humidity sensor and its production, can solve the problems of poor adhesion between wet film and electrode base material, unsatisfactory long-term stability and reliability, and constraints Practical application and further development and other issues, to achieve the effect of good wet response characteristics, high stability, high water resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Electrode cleaning

[0023] The glass-ceramic interdigitated gold electrodes were soaked and cleaned in absolute ethanol and acetone, and dried for later use.

[0024] 2. Preparation of γ-aminopropyltriethoxysilane quaternary ammonium salt

[0025] Add γ-aminopropyltriethoxysilane and n-butane bromide in a molar ratio of 1:2 to react, and react in an argon atmosphere at 40°C for 30 hours for quaternization; then raise the temperature to 50°C at The hydrolysis reaction was carried out under acidic conditions for 3 hours; it was precipitated with ether and dried in vacuum to obtain γ-aminopropyltriethoxysilane quaternary ammonium salt.

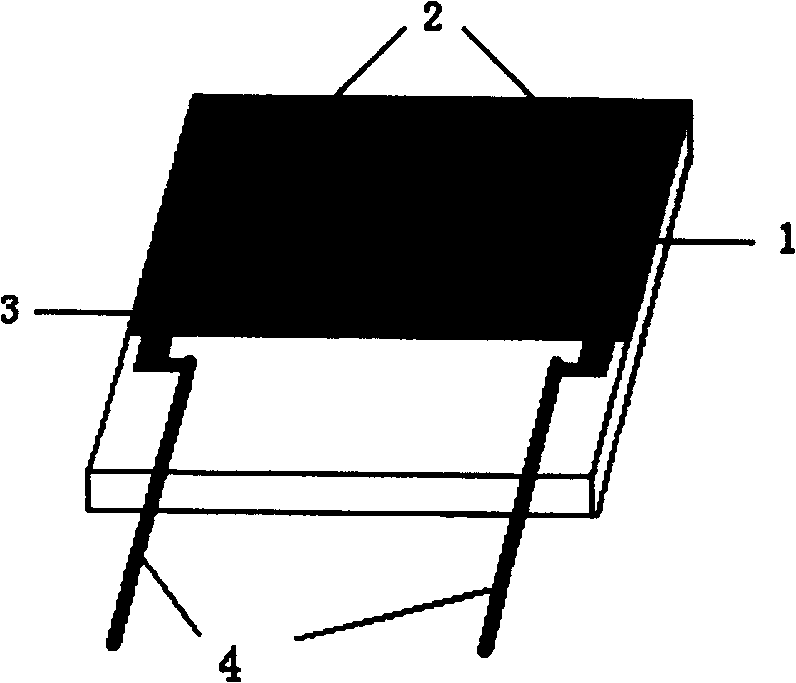

[0026] 3. Preparation of moisture-sensitive film and post-treatment by dip coating

[0027] Adopt dip-coating machine to immerse the glass-ceramic interdigitated gold electrode in the moisture-sensitive liquid (the dehydrated ethanol solution of the gamma-aminopropyl triethoxysilane quaternary ammonium salt of 30% by weight concentra...

Embodiment 2

[0031] 1. Electrode cleaning is the same as in Example 1

[0032] 2. Preparation of γ-aminopropyltriethoxysilane quaternary ammonium salt

[0033] Add γ-aminopropyltriethoxysilane and n-bromobutane in a molar ratio of 1:1 to react, and react in an argon atmosphere at 45°C for 25 hours for quaternization; then heat up to 60°C in The hydrolysis reaction was carried out under acidic conditions for 2 hours; it was precipitated with ether and dried in vacuum to obtain γ-aminopropyltriethoxysilane quaternary ammonium salt.

[0034] 3. Preparation of moisture-sensitive film and post-treatment by dip coating

[0035] Adopt dip-coating machine to immerse the glass-ceramic interdigitated gold electrode into the moisture-sensitive solution (the absolute ethanol solution of the gamma-aminopropyltriethoxysilane quaternary ammonium salt of 40% by weight concentration), after 2 minutes, with Pull at a speed of 4mm / second, take it out and place it in a constant temperature oven, and heat-tr...

Embodiment 3

[0040] 1. Electrode cleaning is the same as in Example 1

[0041] 2. Preparation of γ-aminopropyltriethoxysilane quaternary ammonium salt

[0042] Add γ-aminopropyltriethoxysilane and n-butane bromide in a molar ratio of 1:0.5 to react, and react in an argon atmosphere at 50°C for 20 hours for quaternization; then raise the temperature to 70°C in The hydrolysis reaction was carried out under acidic conditions for 1 hour; precipitation with ether and vacuum drying gave γ-aminopropyltriethoxysilane quaternary ammonium salt.

[0043] 3. Preparation of moisture-sensitive film and post-treatment by dip coating

[0044]Adopt dip-coating machine to immerse the glass-ceramic interdigitated gold electrode in the moisture-sensitive liquid (the dehydrated alcohol solution of the gamma-aminopropyltriethoxysilane quaternary ammonium salt of 50% by weight concentration), after 1 minute, with Pull at a speed of 6mm / sec, take it out and place it in a constant temperature oven, and heat-trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com