Inter-axle differential assembly

一种动组件、轴组件的技术,应用在交互轴差动组件领域,能够解决元件耐用性不利影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

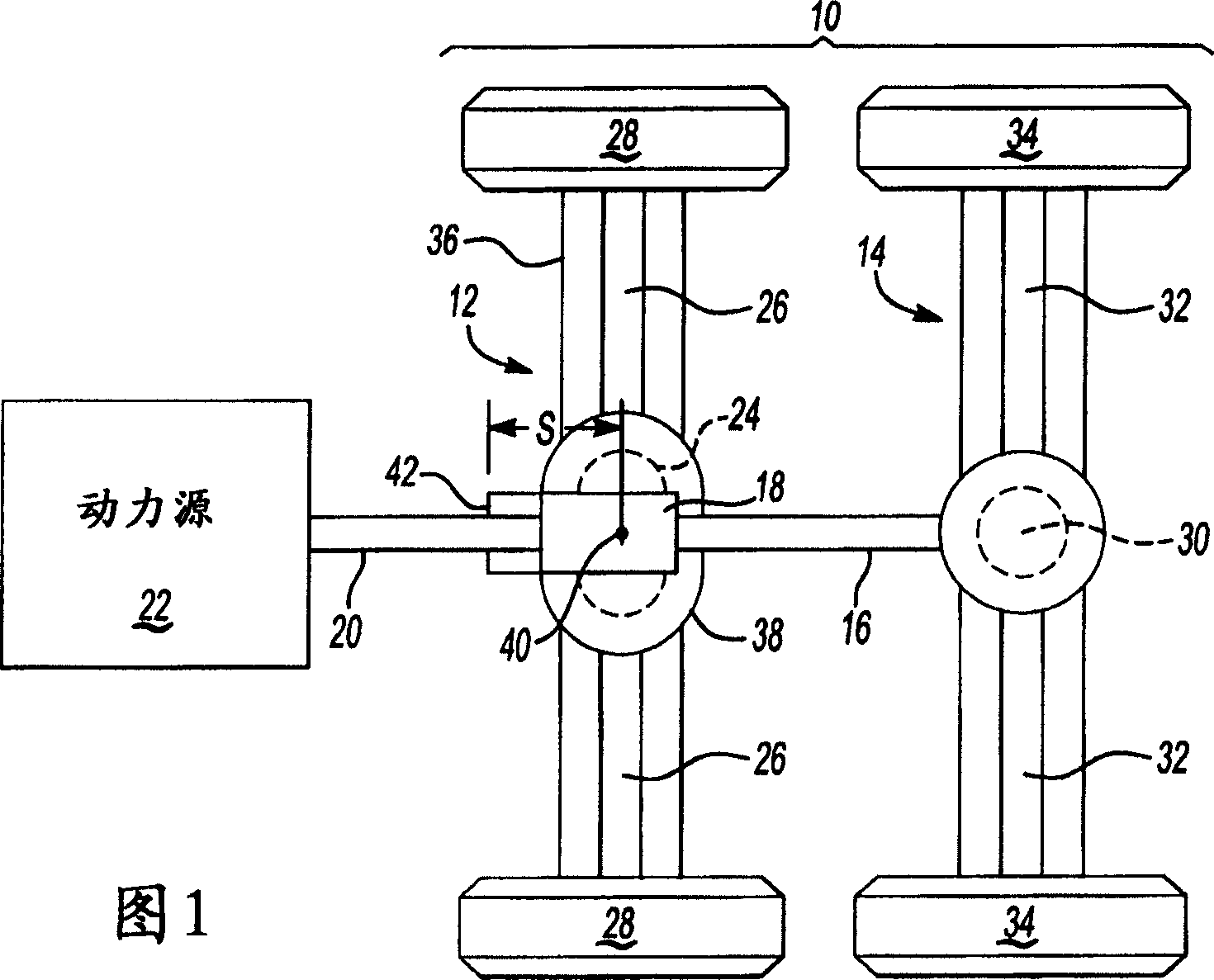

[0022] Shown in FIG. 1 is a tandem drive shaft 10 . The tandem driveshaft 10 includes a front axle 12 and a rear axle 14 coupled to the front axle 12 with a connecting driveshaft 16 . The front axle 12 includes an intershaft differential gear assembly 18 coupled to a drive shaft 20 driven by a power source 22, such as an engine or electric motor. Other powertrain components, such as transmissions, gearboxes, clutches, or any other known powertrain components, may be interposed between the power source 22 and the drive shaft 20 as is known in the art. The cross axle differential gear assembly 18 provides a speed differential between the front axle 12 and rear axle 14 as is known.

[0023] The front axle 12 includes a front differential gear assembly 24 coupled to a front drive shaft 26 for driving a pair of transversely opposed front wheel ends 28 . The rear axle 14 includes a rear differential gear assembly 30 coupled to a rear drive shaft 32 for driving a pair of transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com