Powder drying apparatus

A technology for drying equipment and powder is applied in the field of equipment for baking and drying bamboo and wood powder, which can solve problems such as fire, loss of raw materials, and hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

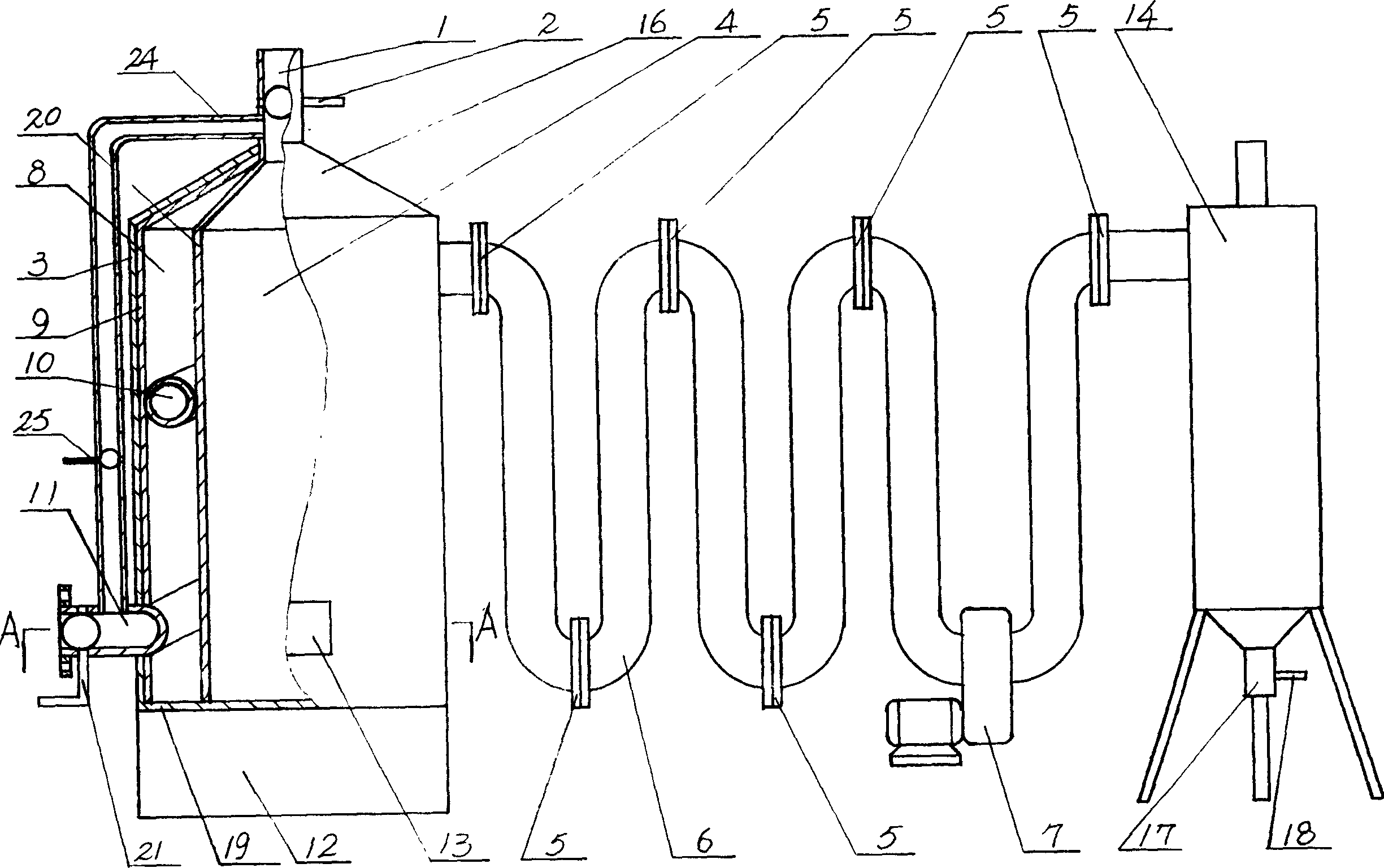

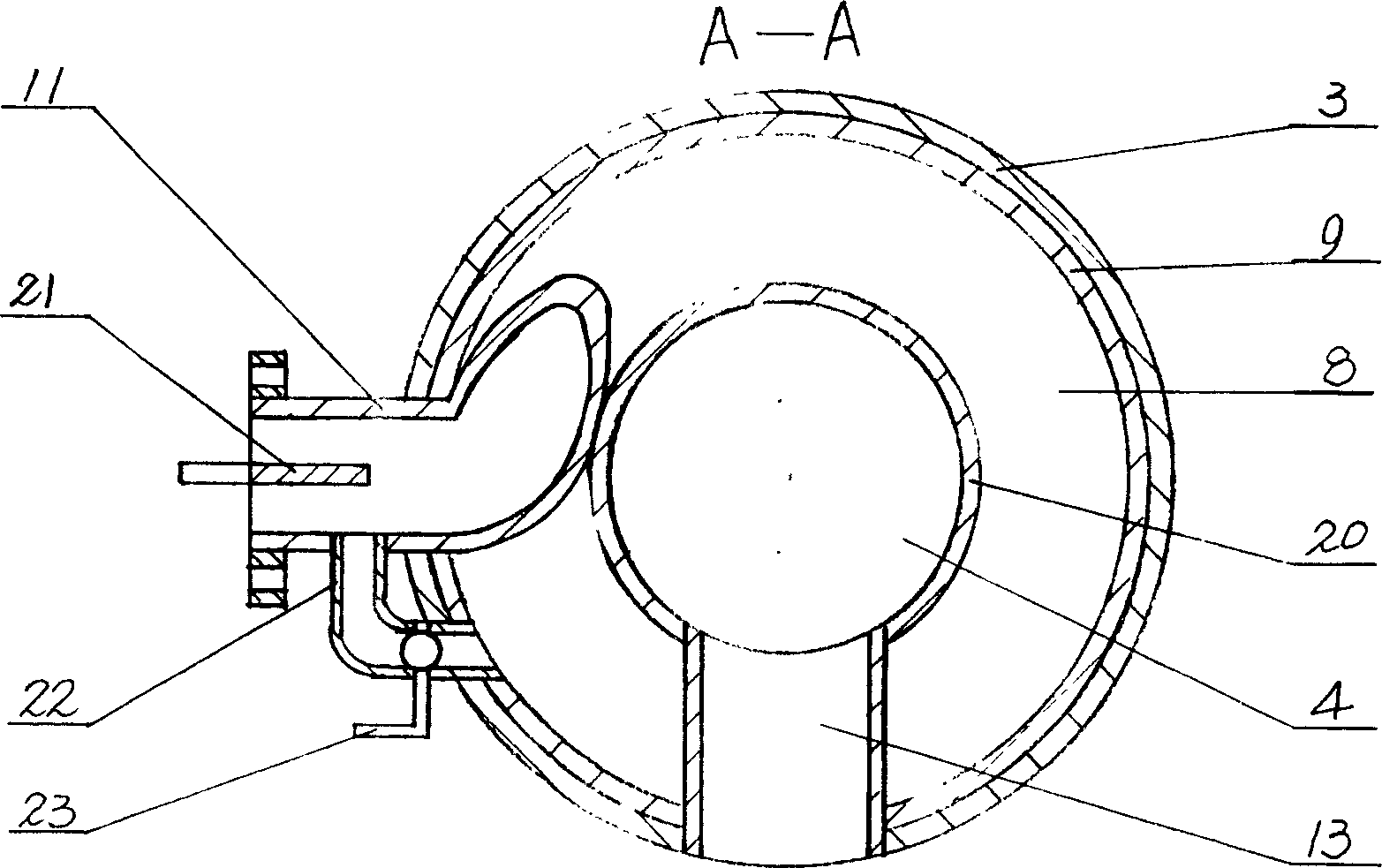

[0013] The powder drying equipment of the present invention includes a baking barrel 16, an external connecting pipe 6, a blower 7, and a storage barrel 14. It is composed of an outer barrel body 3, an inner barrel body 20, a barrel bottom plate 19, a furnace mouth 13, and a flue 1. Chamber 4, the vertical baking barrel 16 of the baking chamber 8, the inner pipe 10 spirally spiraling at least one circle is arranged in the baking chamber 8, the lower end of the inner pipe 10 is connected with the external powder input pipe 11, and the inner pipe 10 The upper end communicates with the external connecting pipe 6 . The inner surface of the outer barrel body 3 is compounded with a thermal insulation layer 9, and the thermal insulation layer 9 can be an asbestos board. The powder input pipe 11 is provided with a compensation pipe 22 communicating with the baking cavity 8 , the powder input pipe 11 is provided with a regulating valve 21 , and the compensation pipe 22 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com