Cylindrical lithium rechargeable battery and method for fabricating the same

A cylindrical, recharging technology, which is applied in the manufacture of electrolyte batteries, cylindrical shell batteries/batteries, secondary batteries, etc., can solve problems such as sparks, uneven welding strength, and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention discloses a cylindrical lithium rechargeable battery and a manufacturing method thereof. In this battery, the anode tab of the electrode assembly is connected to the cylindrical case by laser welding instead of resistance welding, thereby reducing the amount of impurities and preventing the electrode assembly from being damaged by possible sparks during the resistance welding process. In addition, this provides uniform weld strength between the anode tab and the cylindrical casing.

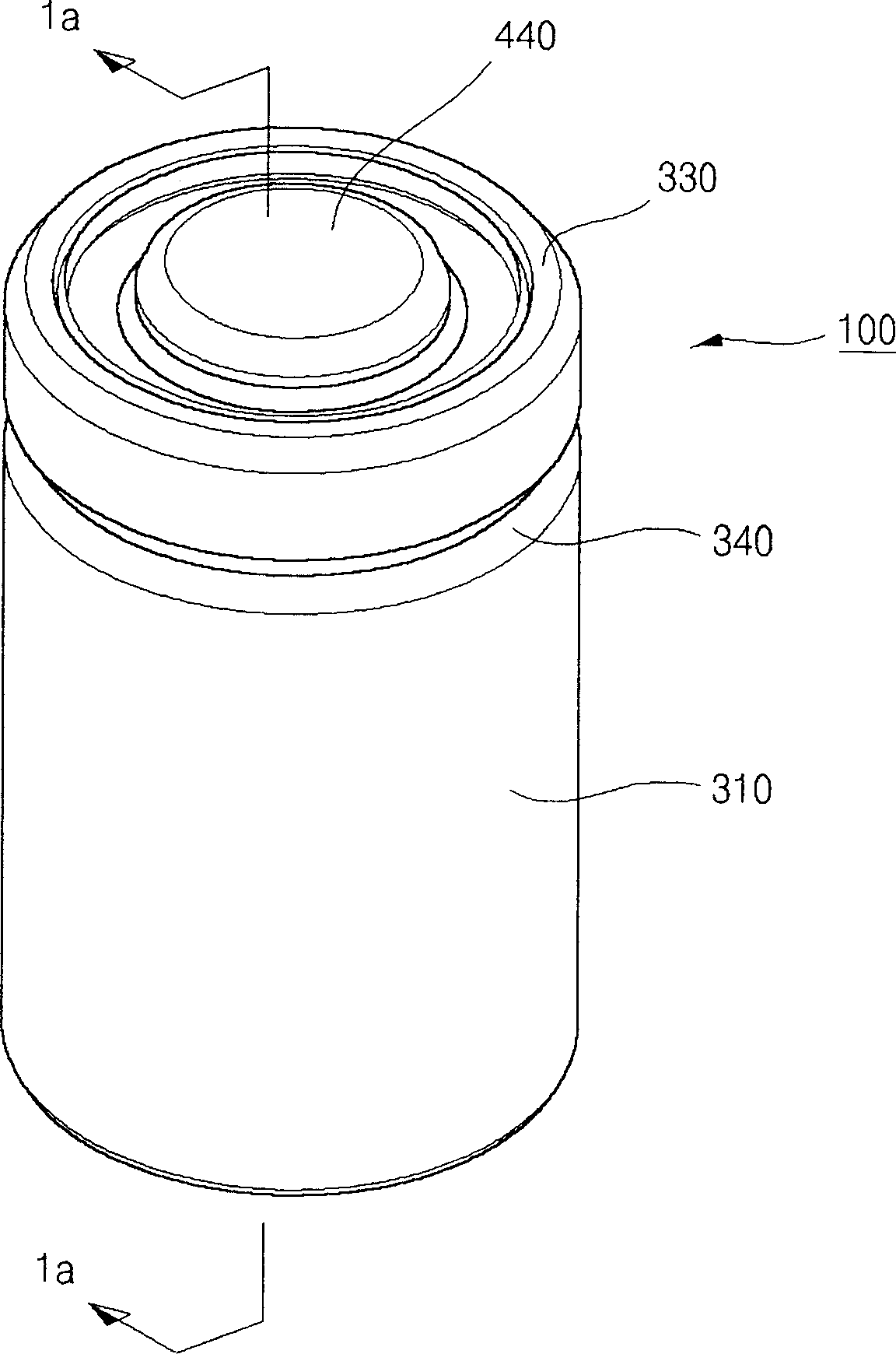

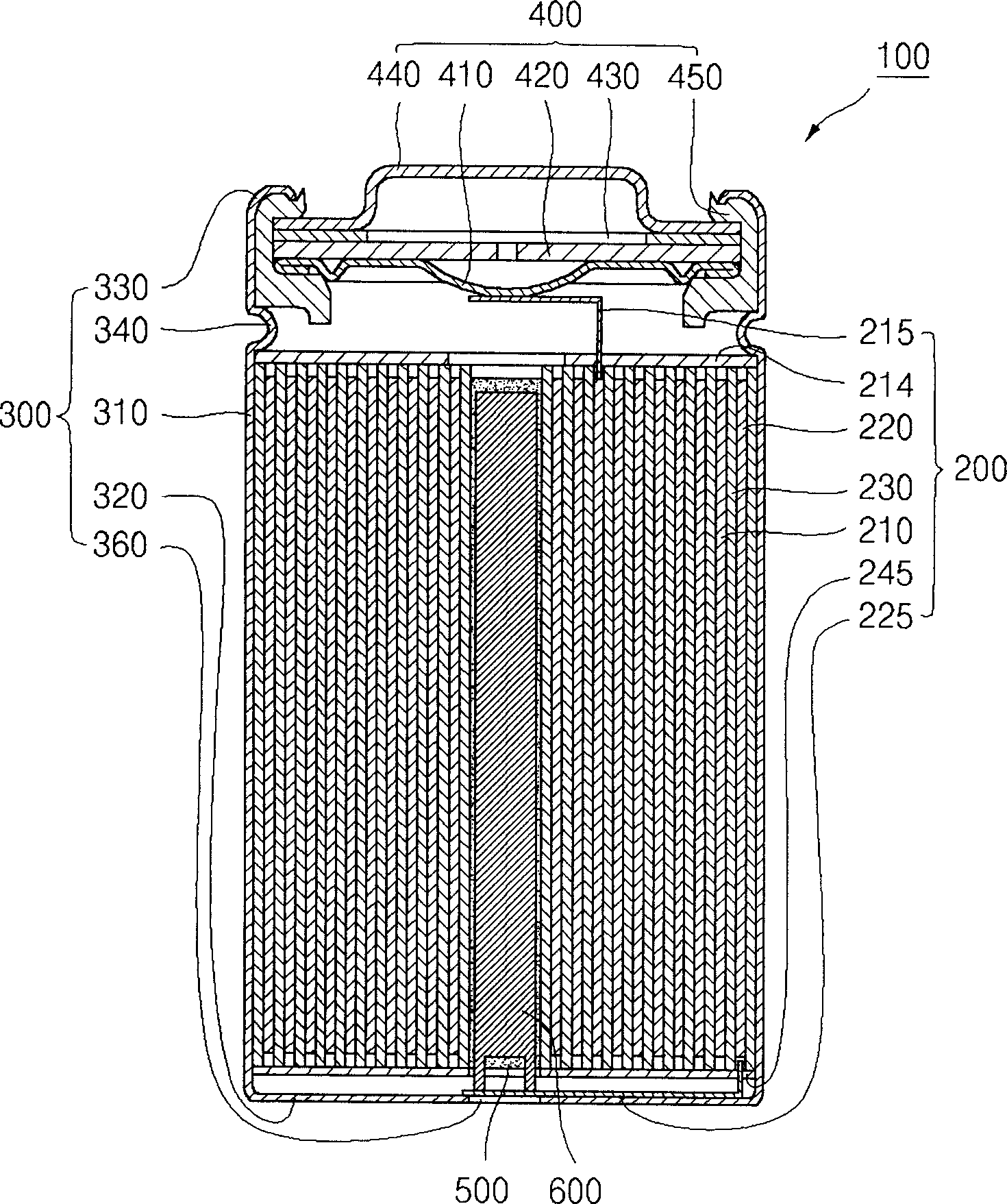

[0025] Figure 1a is a perspective view of a cylindrical lithium rechargeable battery 100 according to an exemplary embodiment of the present invention, Figure 1b for along Figure 1a Cross-sectional view of line "1a-1a" shown.

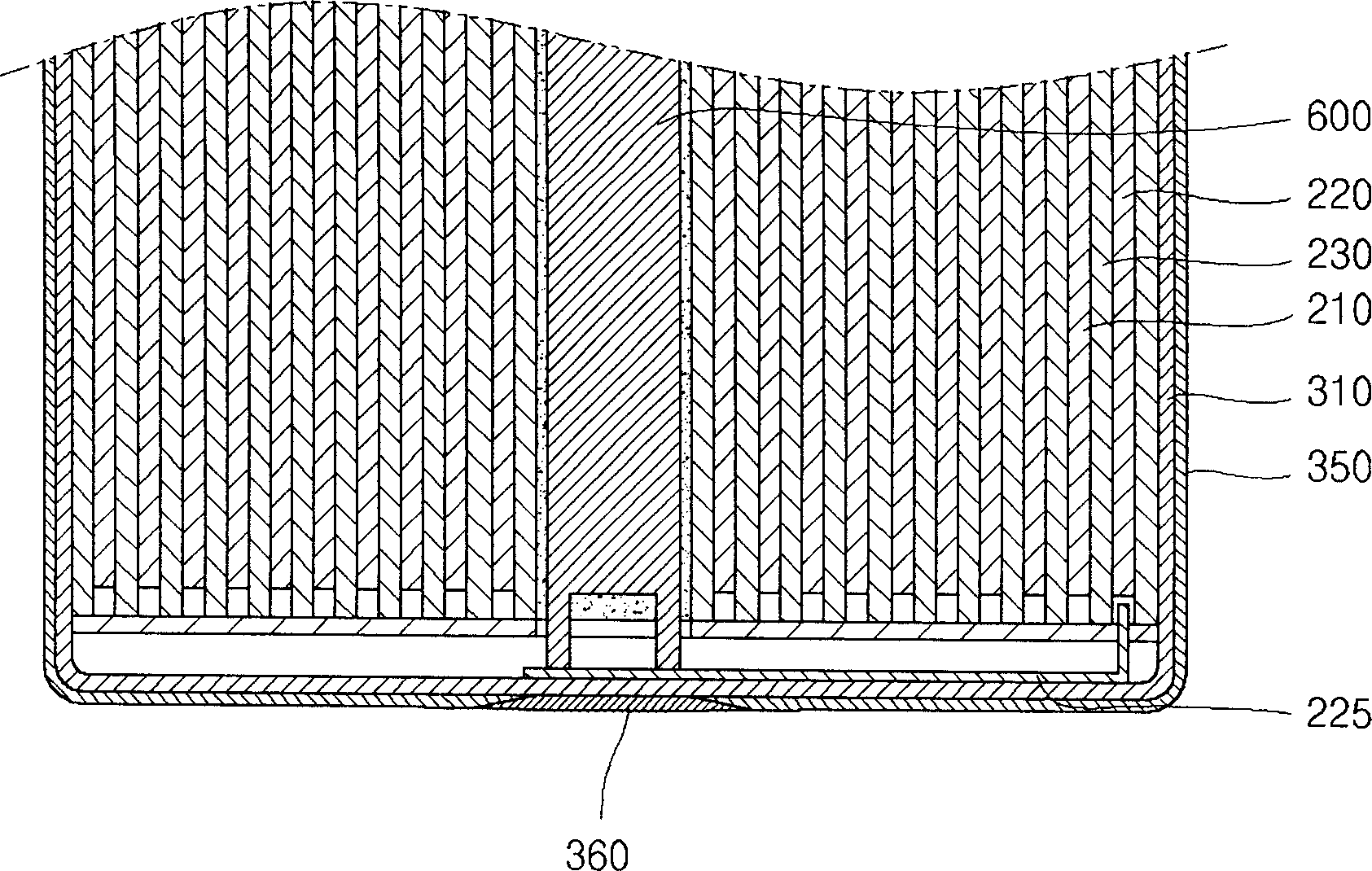

[0026] Such as Figure 1a and 1b As shown, the cylindrical lithium rechargeable battery 100 includes: an electrode assembly 200 generating voltage during charging and discharging, a cylindrical case 300 for accommodating the electrode assembly 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com