Linear actuator

A technology of linear actuators and coils, applied to magnetic objects, machines/engines, electromechanical devices, etc., can solve the problems of difficult to compact devices, inability to manufacture at low cost, and limited scope of use, reducing power consumption, The effect of smooth magnetic transmission and overall compactness of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

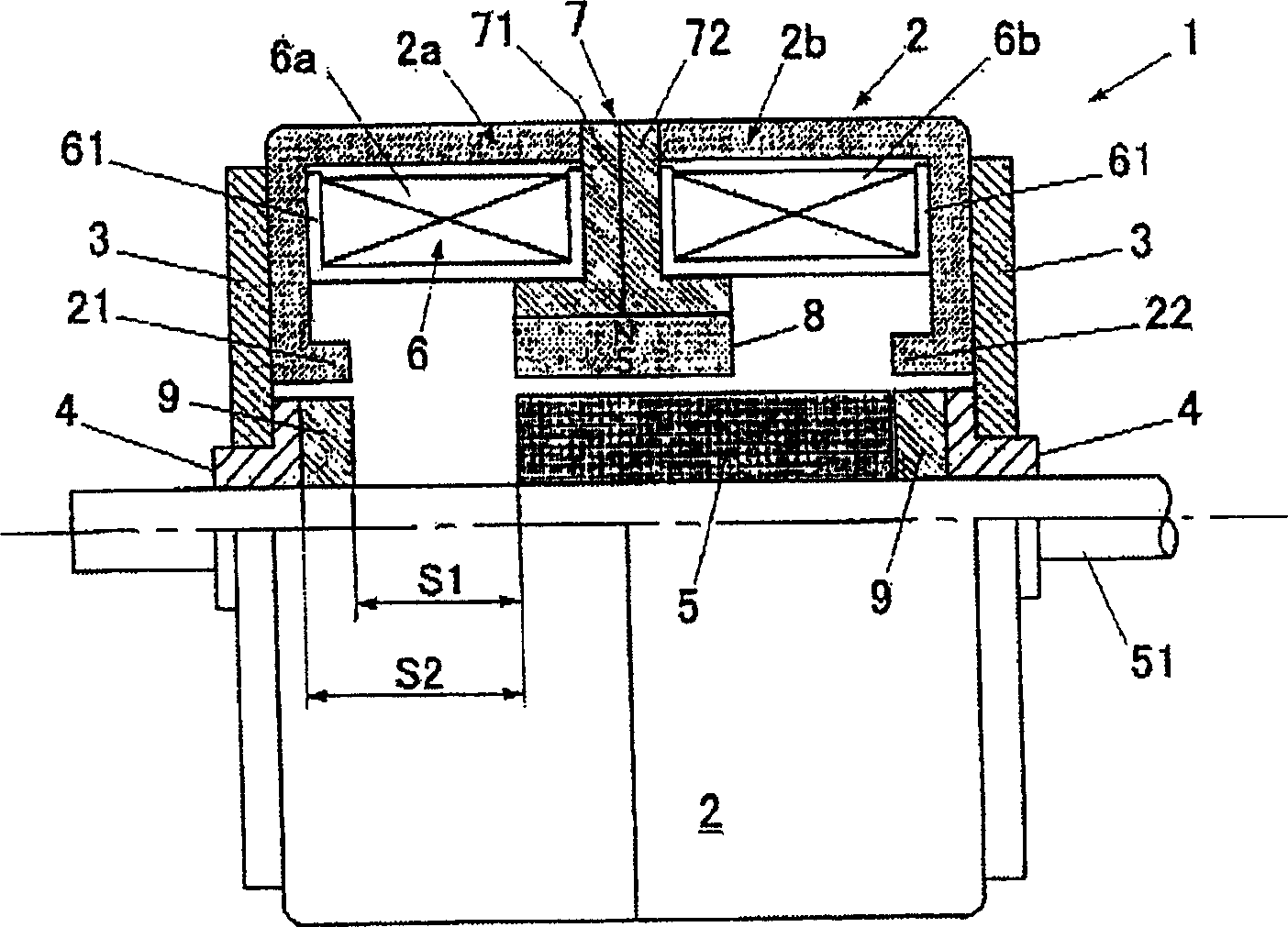

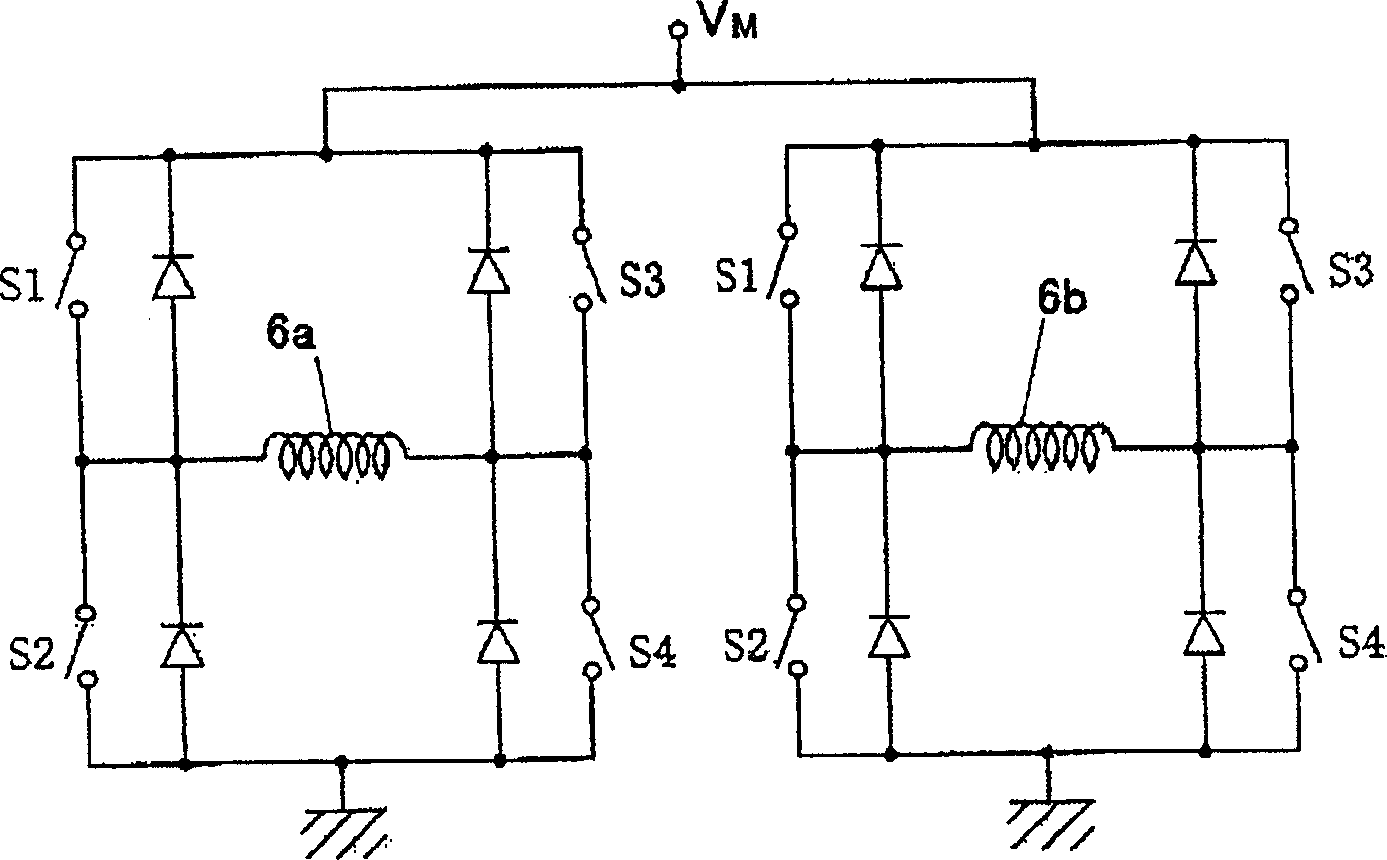

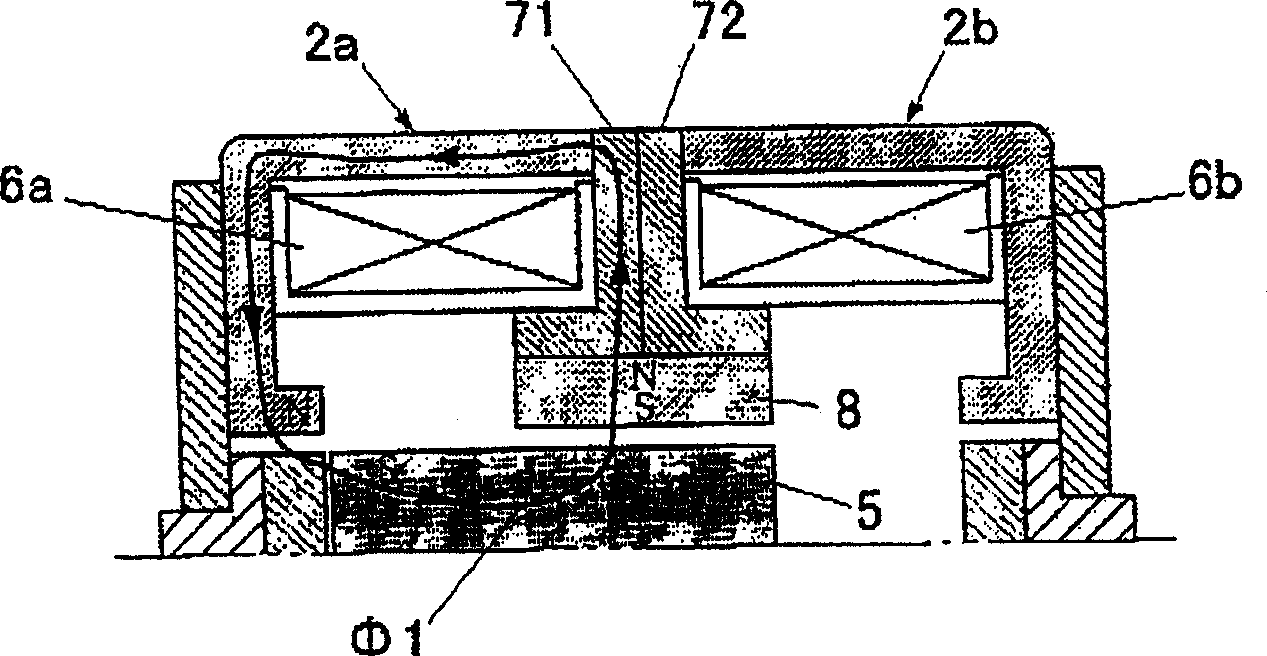

[0017] A linear actuator exemplified by an embodiment of the present invention as a best mode will be described in detail below with reference to the accompanying drawings. figure 1 is the half-section structure diagram of the linear actuator, figure 2 This is an explanatory diagram of the magnetic circuit of the coil. As shown in the figure, reference numeral 1 is a linear actuator including a yoke 2 composed of a cylindrical body forming a main body of the linear actuator and iron, magnetic stainless steel, etc. forming a magnetic circuit, Bearings 4, 4 provided at the centers of flanges 3, 3 arranged on both sides of the yoke 2 and a mover 5 having a shaft portion 51 mounted on the bearings 4 so as to be movable in the axial direction, Coils 6 ( 6 a , 6 b ) wound on a resin bobbin 61 provided on the inner wall of the yoke are arranged in the yoke 2 , and stator magnets 8 made of permanent magnets are arranged between the coils 6 and the mover 5 .

[0018] Said coil 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com