Key switch structure

A switch and structure technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problem of difficult to achieve long stroke, and achieve the effect of increasing the stroke length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] (constitute)

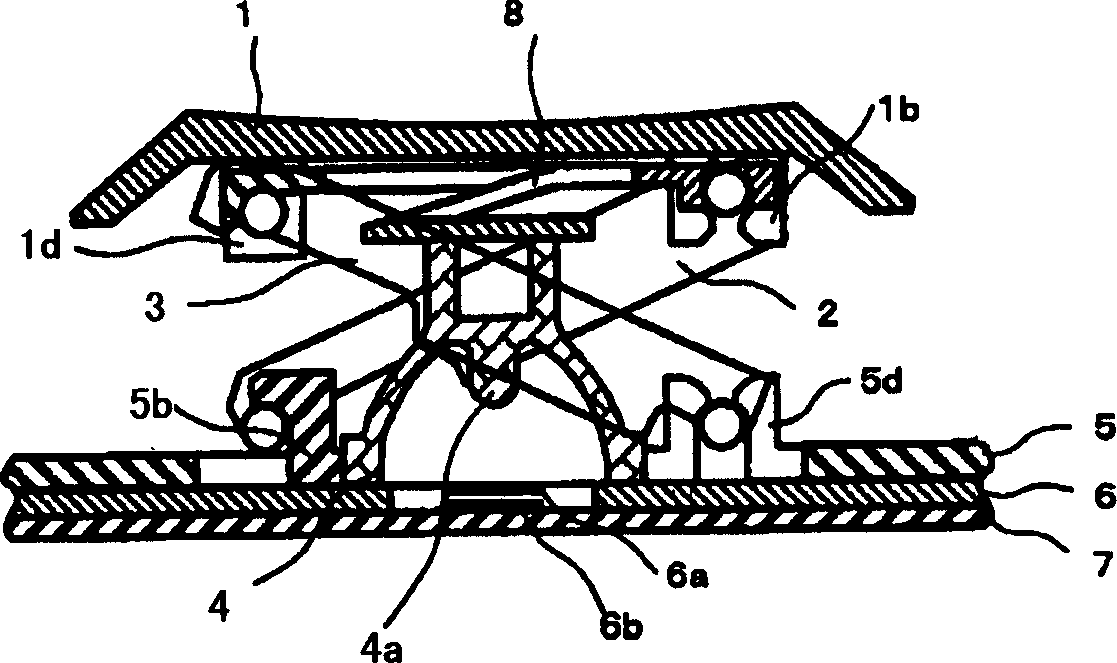

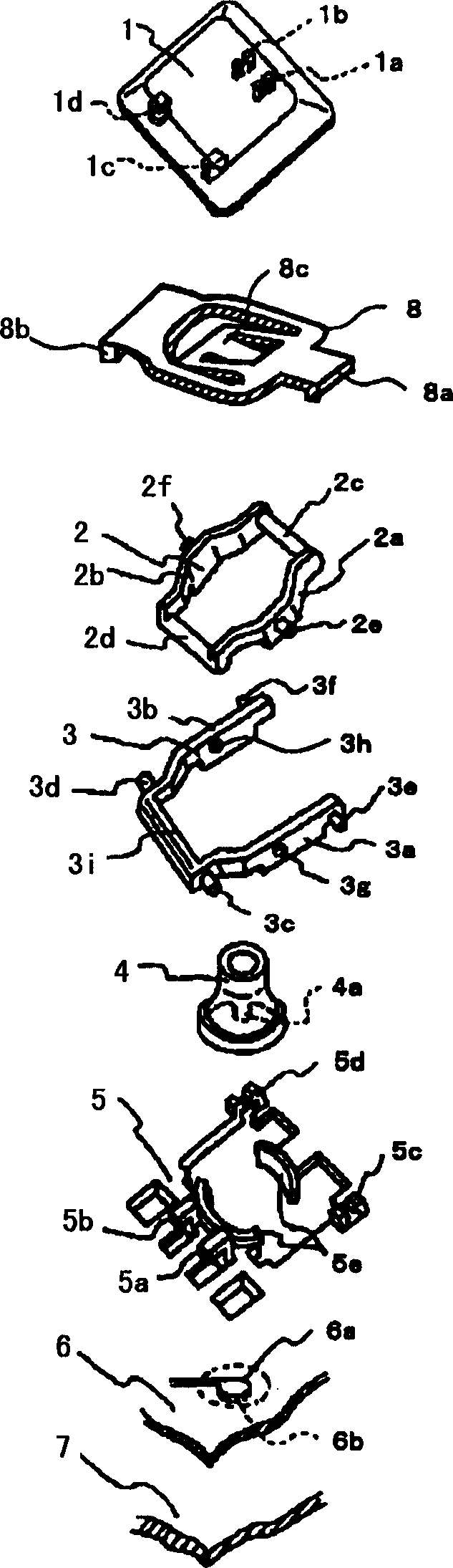

[0028] figure 1 It is a structural diagram showing the key switch of the embodiment, figure 2 It is an exploded perspective view showing the push switch of the embodiment.

[0029] The key switch of the embodiment is composed of a key tip 1 , a first link member 2 , a second link member 3 , a cup rubber 4 , a case 5 , a contact piece 6 , a base plate 7 and a spring portion 8 .

[0030] On the key top end portion 1, there are provided rotation support portions 1a, 1b that rotatably support one end of the first link member 2, and figure 1 In the horizontal direction, the sliding support portions 1c, 1d at one end of the second link member 3 are slidably supported.

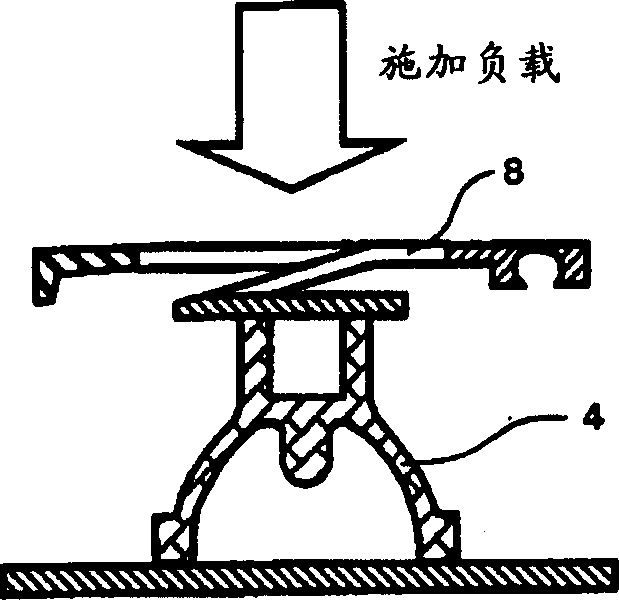

[0031] As shown in the figure, the spring part 8 is formed by, for example, stamping and bending an aluminum plate to provide fixing parts 8a, 8b and a spring 8c. In this way, the fixing portion 8a is disposed on the first connecting rod 2c described later of the first link member 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com