Automatic universal board loading machine

An automatic loading machine, general-purpose technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of high physical strength, low work efficiency, insufficiency, etc., and achieve the effect of increasing the stroke length, being practical and convenient, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

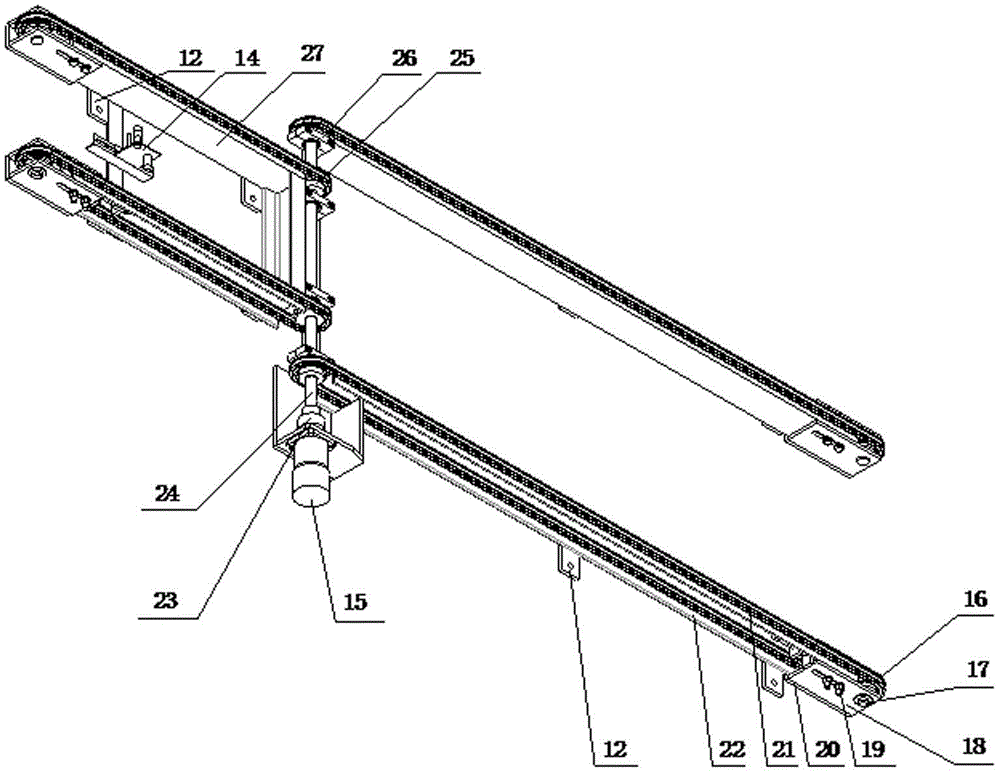

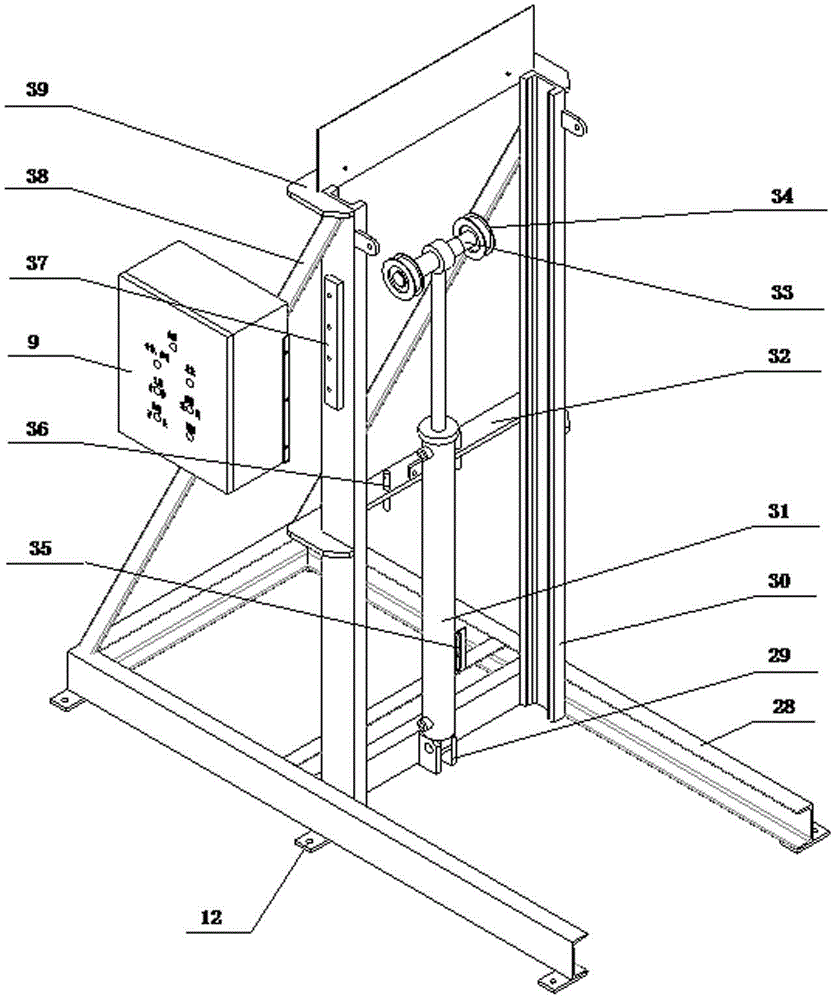

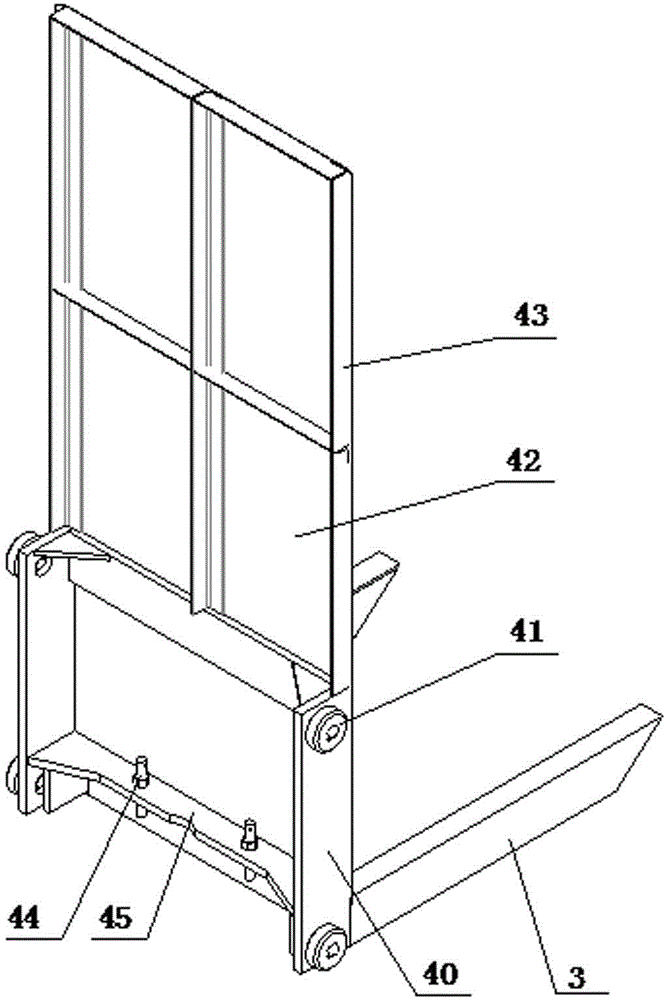

[0029] Below in conjunction with accompanying drawing, the structure of the universal type automatic plate loading machine of the present invention is described in detail.

[0030] see Figure 1 to Figure 9 , the overall structure of the general-purpose automatic plate loading machine of the present invention is that a door frame 4 is fixed on the foundation plate 12, and the door frame 4 is used as the installation frame of each component, and the door frame 4 is provided with two columns 30 up and down along the door frame 4. The movable sliding frame 5 is provided with a ground rail 1 between the two bases of the door frame 4, and the small end of the ground rail 1 stretches into the front of the sliding frame fork 3, and a scraper frame 10 is established on the two columns 30 of the door frame 4, On the scraper rail of the scraper frame 10, a double-layer trimmer 6 is provided through the rail 7 of the scraper frame. There is a board frame 13 under it, an oil station 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com