Double-speed segmented contact of ultrahigh voltage

An ultra-high voltage and switching technology, which is applied in the field of double-speed breaking contacts of ultra-high voltage switches, can solve the problems affecting the service life of equipment, power consumption, and increase production costs, so as to reduce the volume of the operating mechanism, shorten the arcing time, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

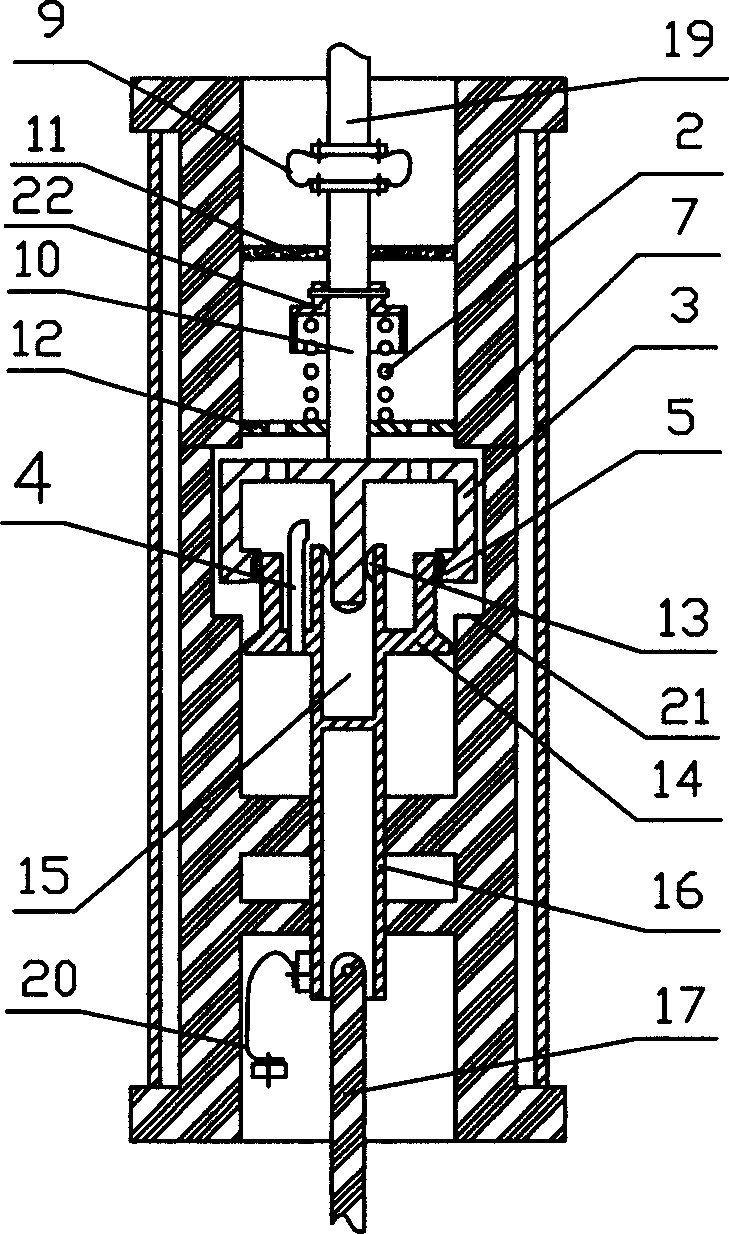

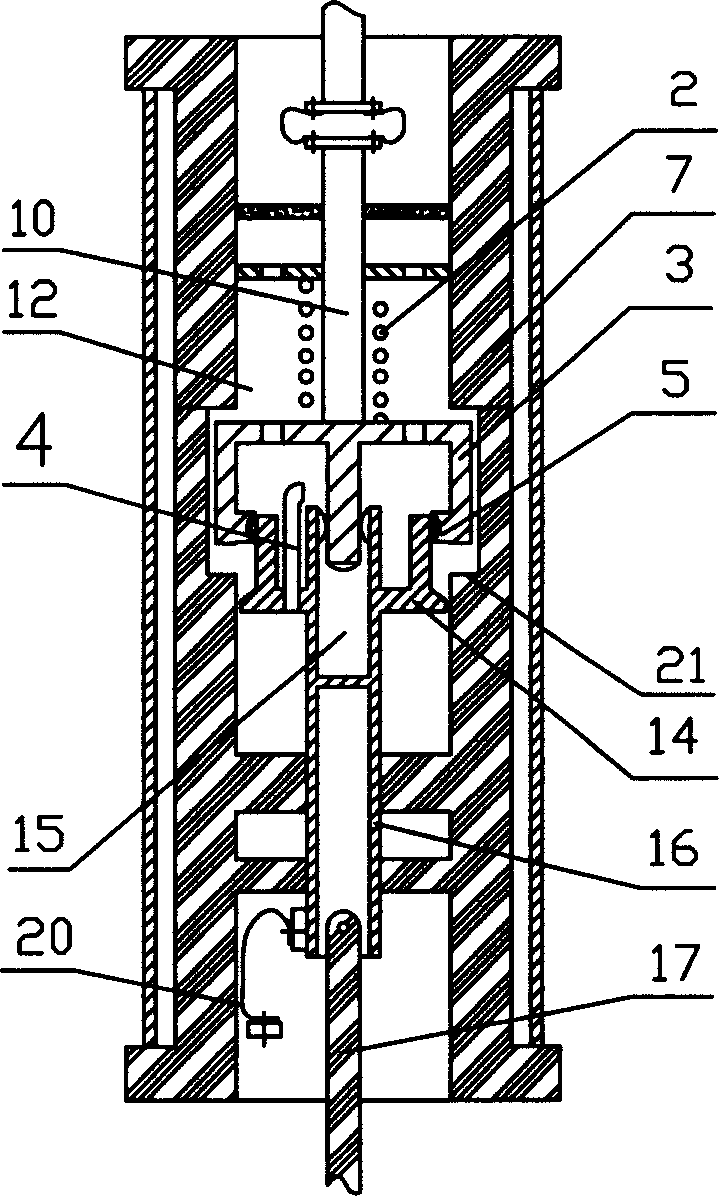

[0017] Such as figure 1 As shown, the UHV switch double-speed breaking contact of the present invention includes an insulating cylinder 7 and a static contact 3 arranged in the insulating cylinder 7, the static contact 3 and the insulating cylinder 7 are connected by a spring 2, and the static contact 3 There is a load static contact 5 on the contact surface with the moving contact 14, and the inner wall of the insulating cylinder 7 has a blocking step 21 for preventing the movement of the static contact 3. The static contact 3 has a disc-shaped static contact base with a through hole, the center of the static contact base has a columnar arc-extinguishing contact, and multiple load static contacts 5 are distributed around the base ; Correspondingly, the moving contact 14 has a disc-shaped moving contact base, the moving contact base has an arc blowing tube 4 that runs through it, and the upper end of the arc blowing tube 4 faces the arc extinguishing contact of the static cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com