Method and device for treating base bored

A substrate processing method and substrate processing device technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of difficulty in dispersing to the surface of the substrate, difficulty in dispersing, uneven treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The best embodiments of the present invention will be described below with reference to the accompanying drawings.

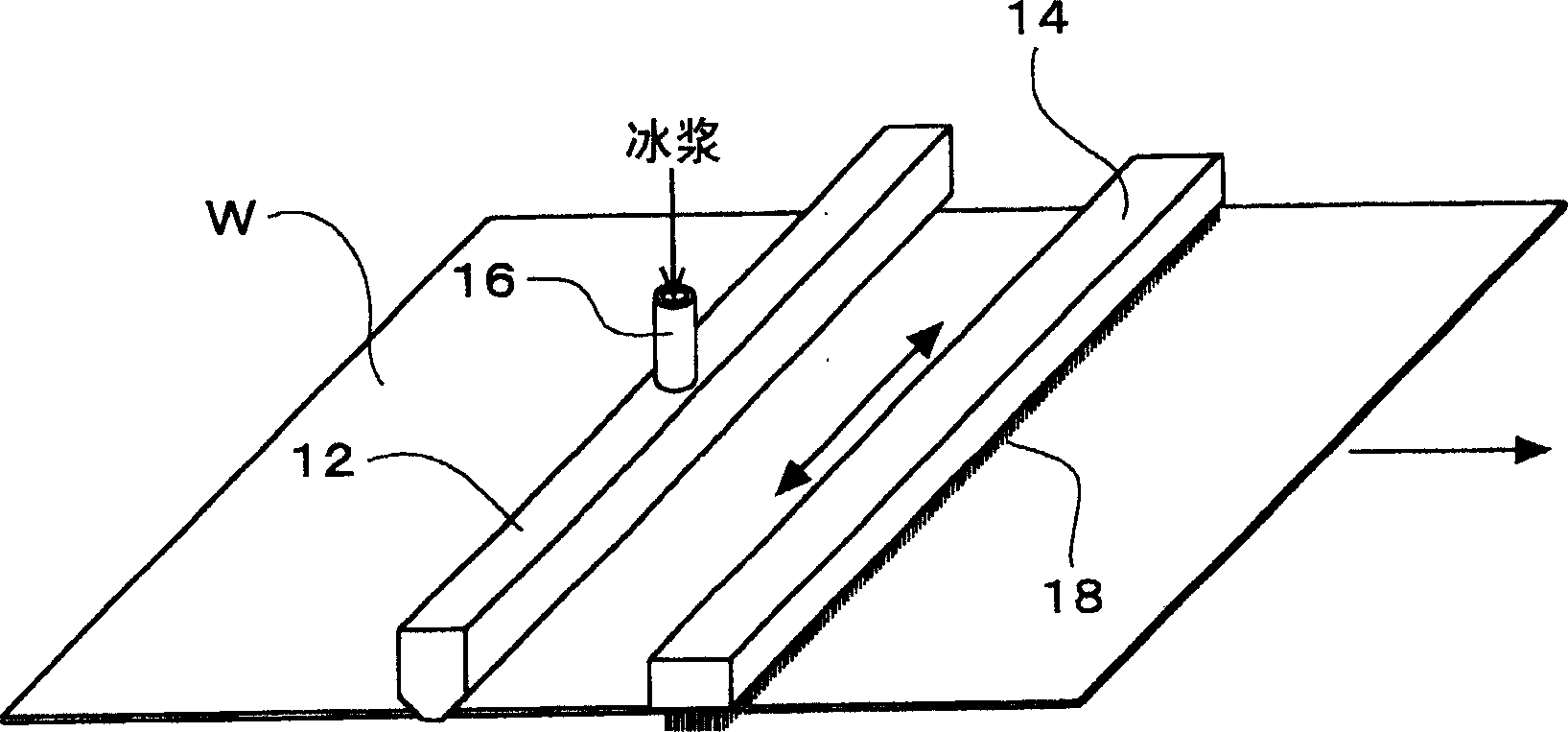

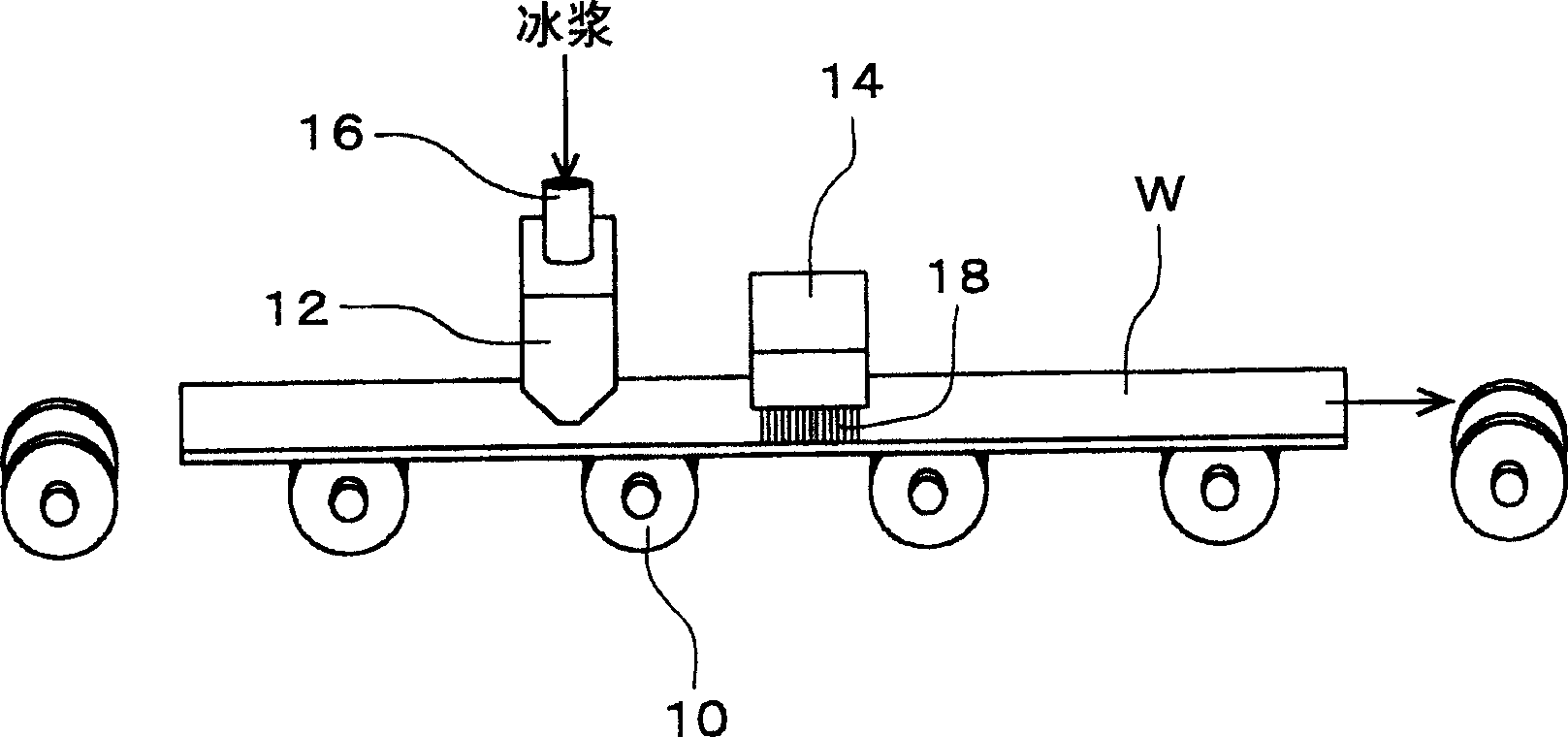

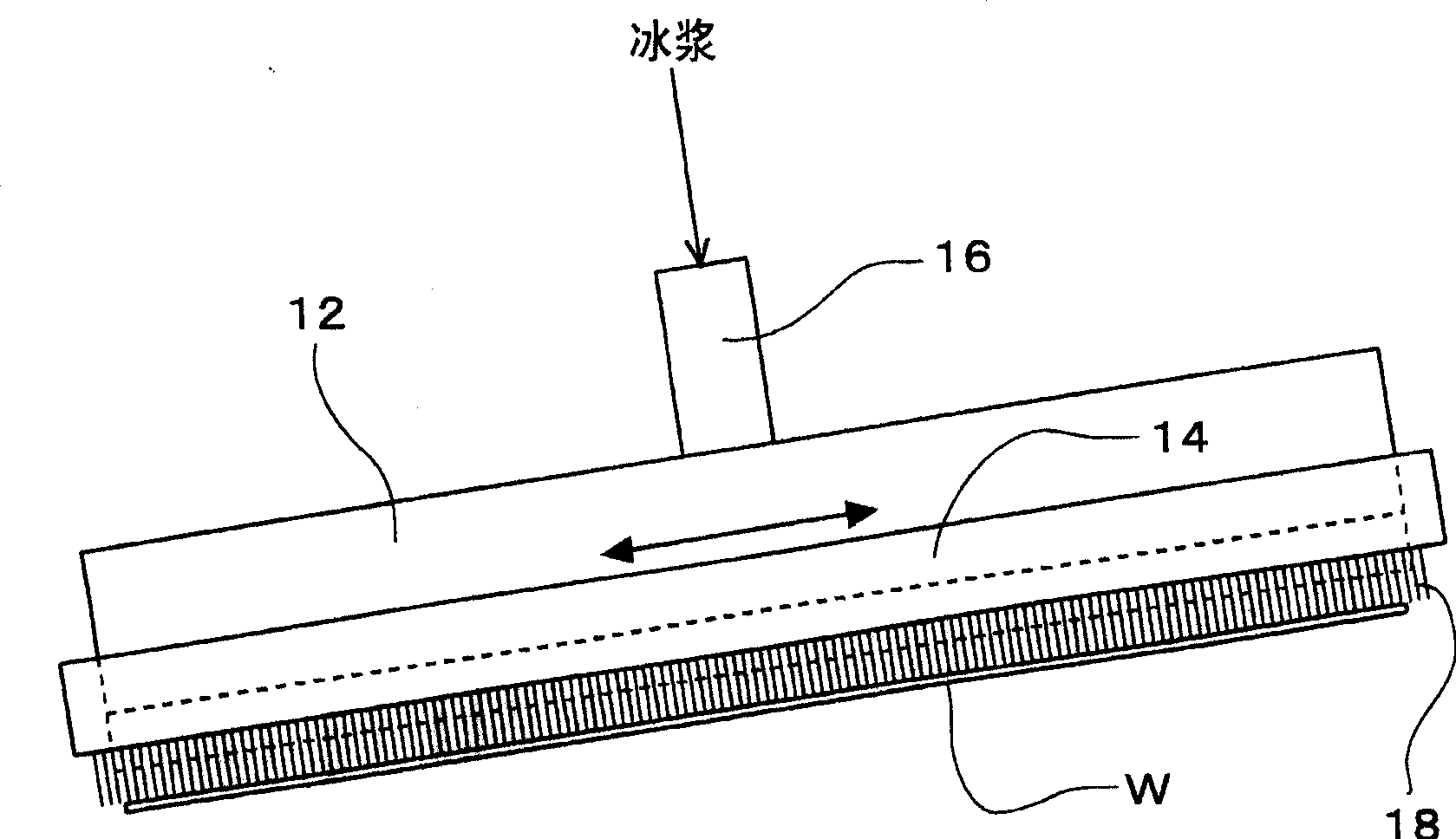

[0064] Figure 1 to Figure 4 An example of an embodiment of the present invention is shown. figure 1 It is a perspective view showing a main part of a substrate processing apparatus, and a schematic configuration of a substrate cleaning apparatus in this example, figure 2 is its front view, image 3 is its side view, Figure 4 It is a schematic cross-sectional view showing the configuration of an ice making and liquid delivery unit which is one of the components of the substrate cleaning apparatus.

[0065] This substrate cleaning apparatus includes: a roller conveyor composed of a plurality of transport rollers 10 arranged in parallel to each other, supports the substrate W in an inclined posture, and transports the substrate W in a direction perpendicular to the inclined direction and in a horizontal direction ( figure 1 as well as image 3 (not sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap