Material treatment device with plasma jet array cooperating with mechanical rotational motion

A technology of plasma and rotary motion, applied in the direction of plasma and electrical components, can solve the problems of small working area, large area of material and uniform processing, etc., and achieve the effect of uniform processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

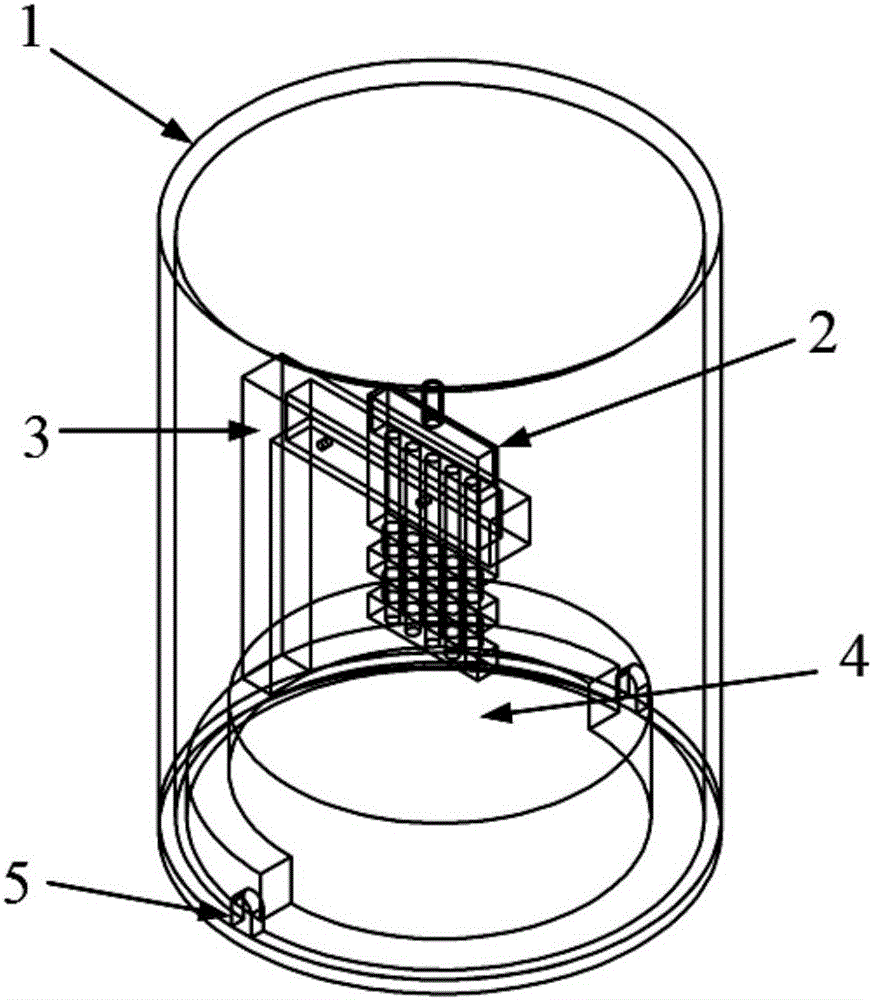

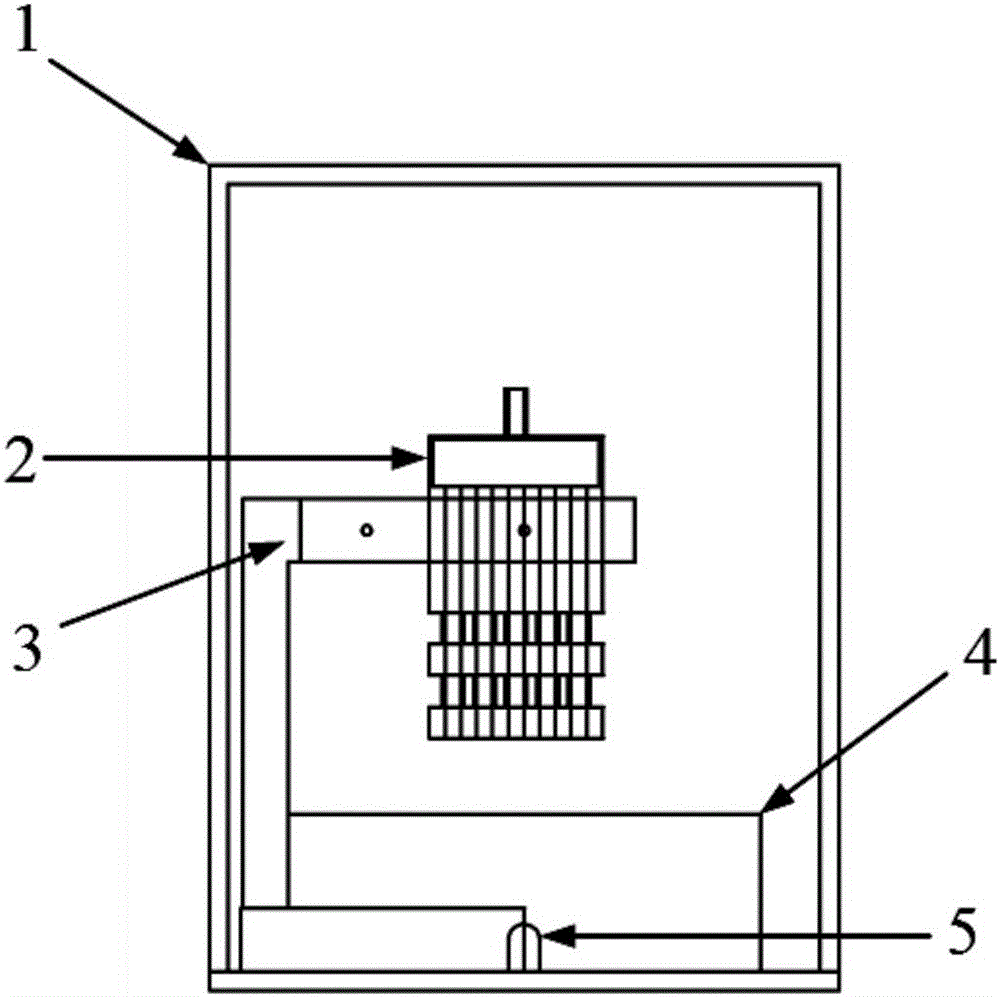

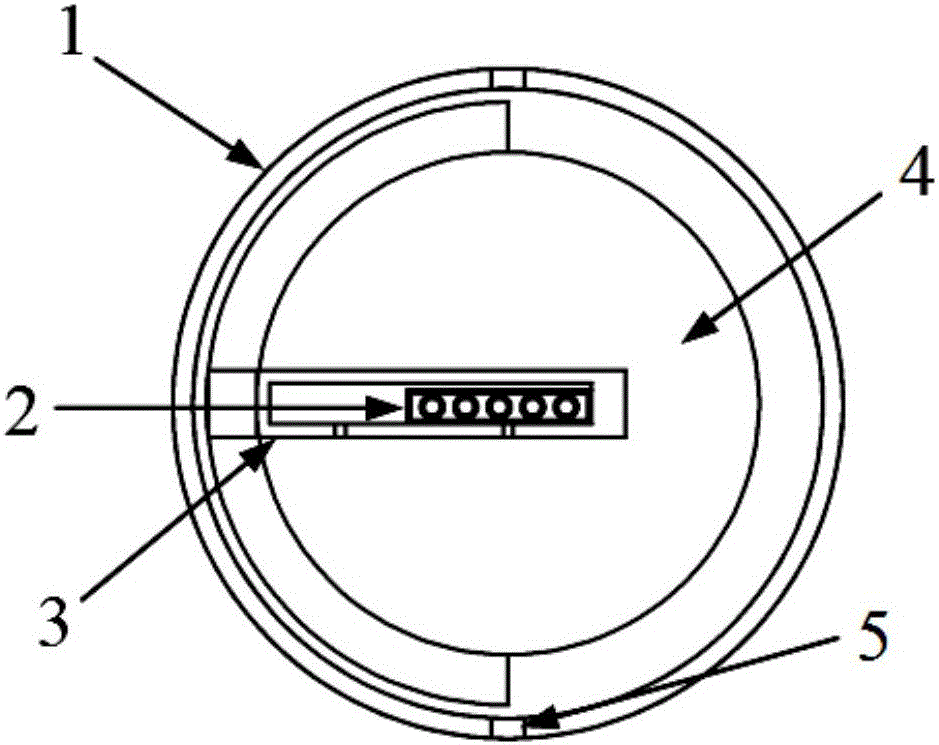

[0024] refer to Figure 1 to Figure 3 , the material processing device of the present invention in which the plasma jet array cooperates with the mechanical rotation movement includes a cavity 1 , a jet array 2 , a support 3 , and a stage 4 . Among them, the multiple uniform plasma jets generated by the jet array 2 are coupled into a large-area uniform low-temperature plasma through the interaction between charged particles; , multi-dimensional adjustment of position and spacing; an electric turntable with adjustable speed is integrated in the stage 4, which can realize the uniform rotational movement of the material to be processed; plasma generation and material processing can be carried out in the cavity 1 according to actual needs . Finally, large-area and uniform treatment of materials with plasma can be achieved.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com