Surface treatment method of low temperature plasma of granular material and device thereof

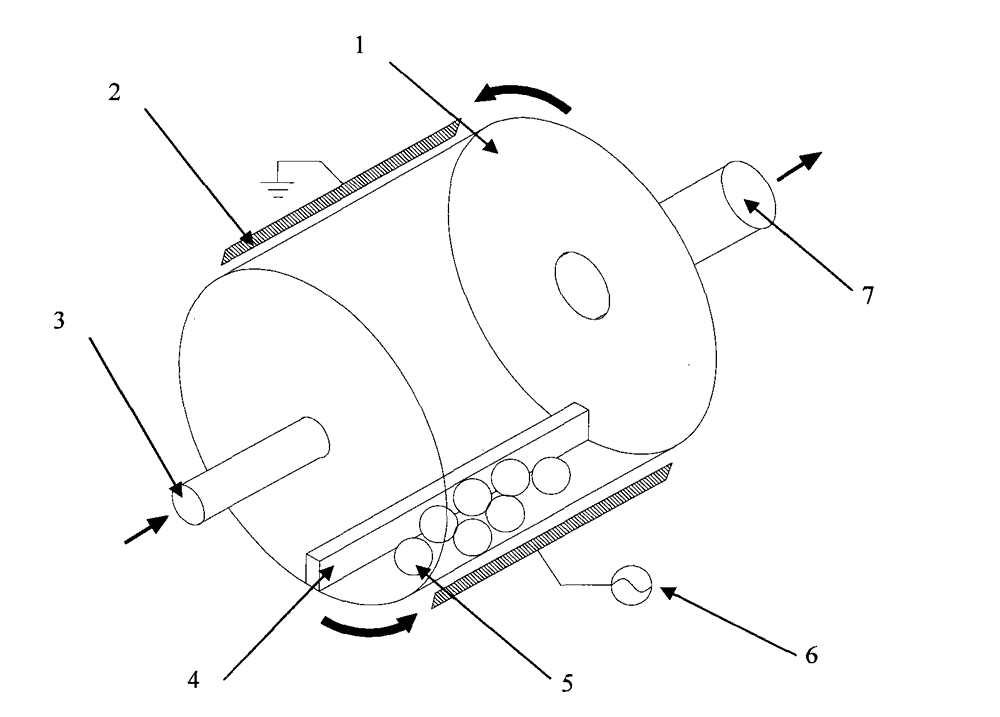

A low-temperature plasma and surface treatment device technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of poor treatment uniformity, poor treatment effect, low treatment efficiency, etc., and achieve simple loading and unloading, convenient operation, and high treatment efficiency high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Low-temperature plasma cleaning treatment on the surface of solder balls

[0024] Weigh 100 grams of tin balls, introduce them into the drum 1, and seal the drum 1. Vacuumize the inside of the drum 1 to 5 Pa, feed oxygen quantitatively, and maintain the vacuum in the drum 1 at 40 Pa. Turn on the drum 1 to rotate and apply a high-frequency electric field to form plasma in the drum 1, maintain a discharge power of 100W, and stop vacuuming and gas feeding after 20 minutes of processing time. Fill the drum 1 with pure air to make the pressure inside and outside the drum 1 equal, then open the drum 1, take out the processed materials, and the treatment is over.

Embodiment 2

[0025] Embodiment 2: Low-temperature plasma activation treatment of plastic parts

[0026] The material of the plastic parts is polypropylene (PP), and the three-dimensional dimensions of the parts are length: 8mm, width: 5mm, height: 4mm.

[0027] 2 grams of plastic parts are weighed, introduced into drum 1, and drum 1 is sealed. Vacuumize the inside of the drum 1 to 5 Pa, feed oxygen quantitatively, and maintain the vacuum in the drum 1 at 40 Pa. Turn on the drum 1 to rotate and apply a high-frequency electric field to form plasma in the drum 1, maintain a discharge power of 150W, and stop vacuuming and gas feeding after 30 minutes of processing time. Fill the drum 1 with pure air to make the pressure inside and outside the drum 1 equal, then open the drum 1, take out the processed materials, and the treatment is over

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap