Energy recovery apparatus and method for plasma display panel

An energy recovery and energy technology, applied in identification devices, static indicators, instruments, etc., can solve the problems of high manufacturing cost and high internal voltage, and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

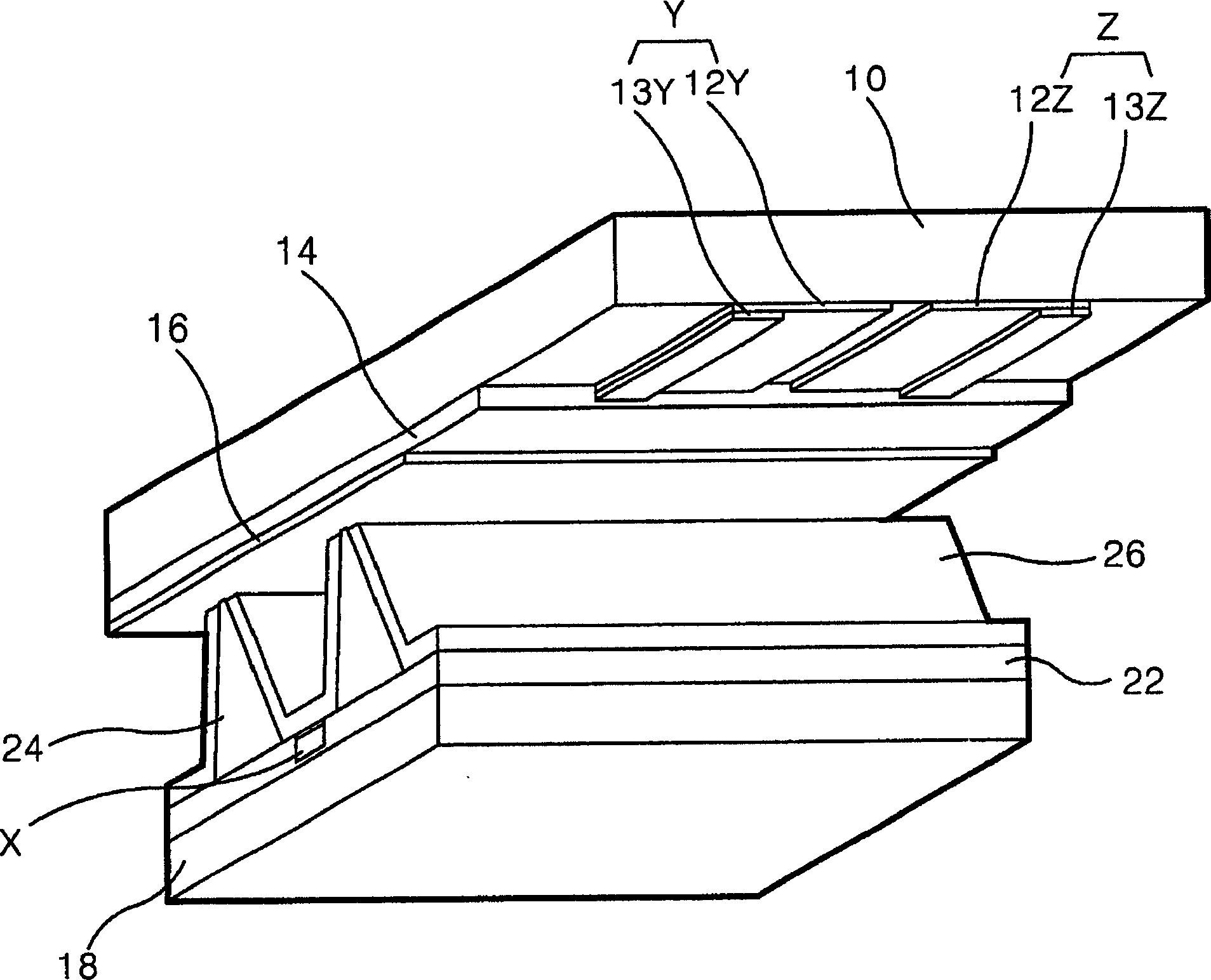

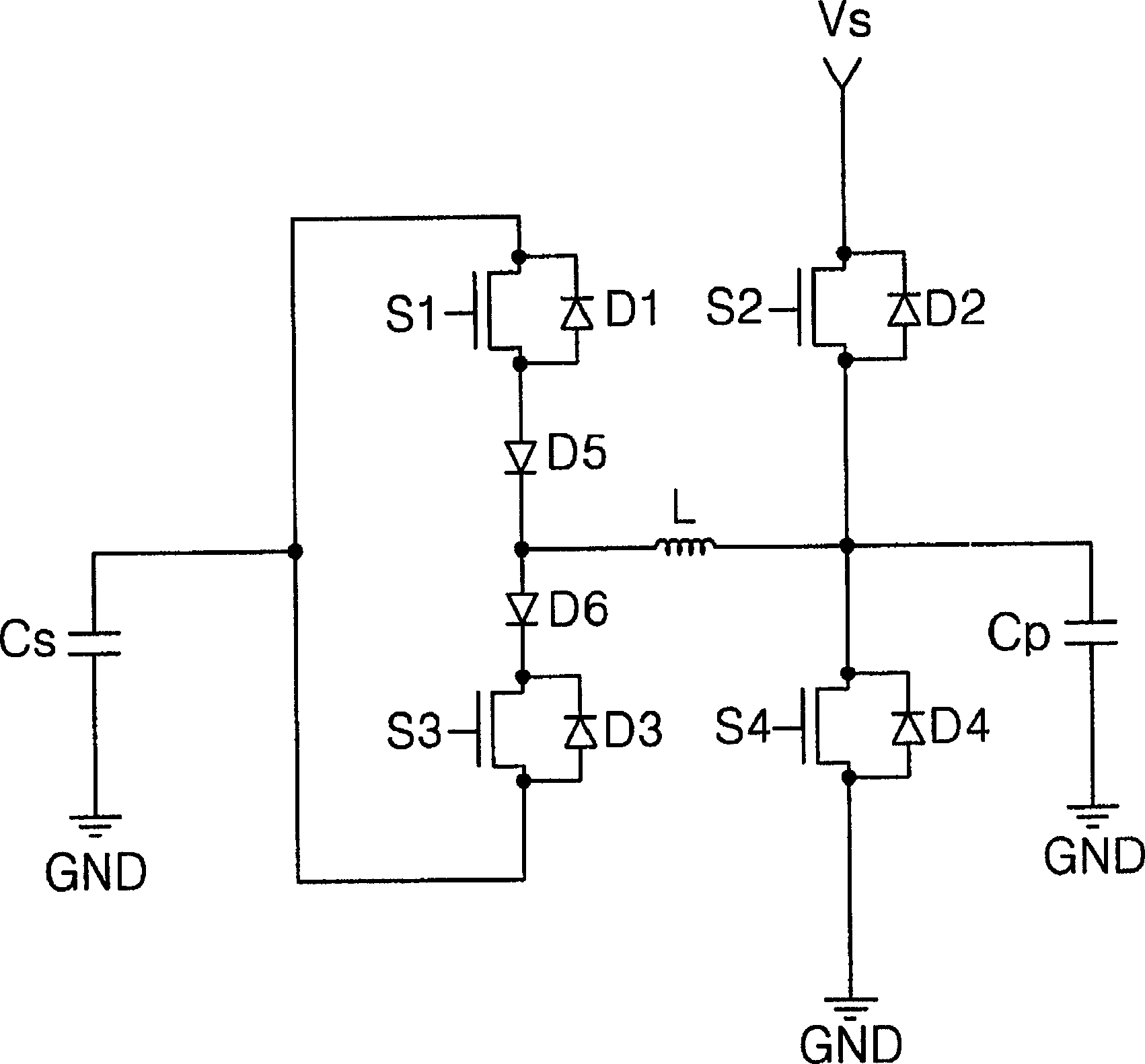

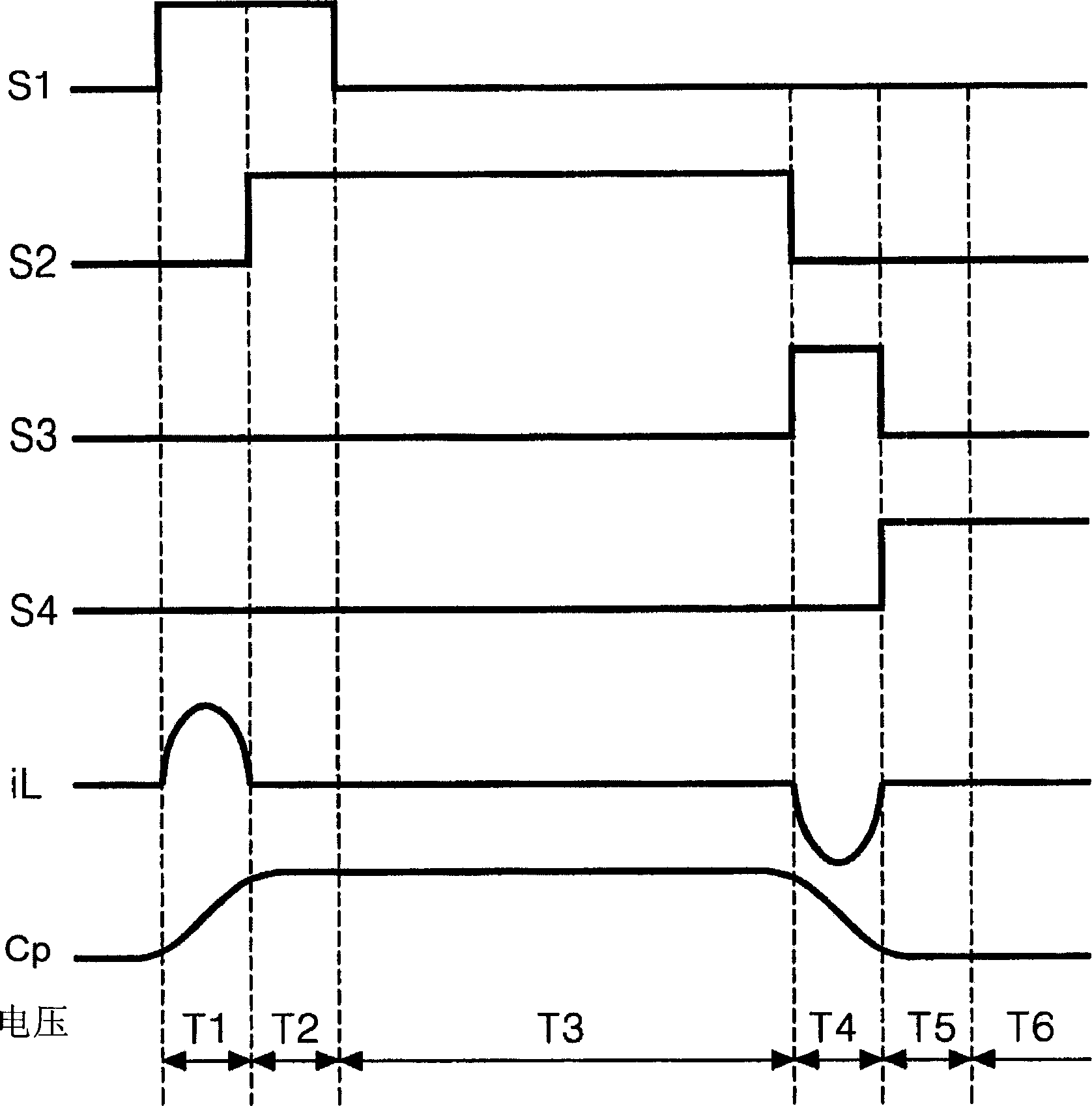

[0033] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the accompanying drawings.

[0034]In order to achieve the above object, according to one aspect of the present invention, the provided energy recovery device includes a capacitive load equivalently formed between the scan electrode and the sustain electrode, which is used to recover the energy charged into the capacitive load and restore the recovered energy An energy recovery unit provided again to the capacitive load, an energy supply unit disposed between the energy recovery unit and the capacitive load, wherein the energy supply unit relays energy between the energy recovery unit and the capacitive load, and supplies the capacitive load a reference voltage to generate a stable discharge in a capacitive load, and an energy relay unit disposed between the energy recovery unit and the energy supply unit for connecting the energy recovery unit and the energy supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap