Surface mounting machine

A surface mount machine and a technology for installation, applied in the direction of electrical components, electrical components, etc., can solve the problems of surface mount machine height increase, limited miniaturization, and restriction of the moving range of the adsorption head, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

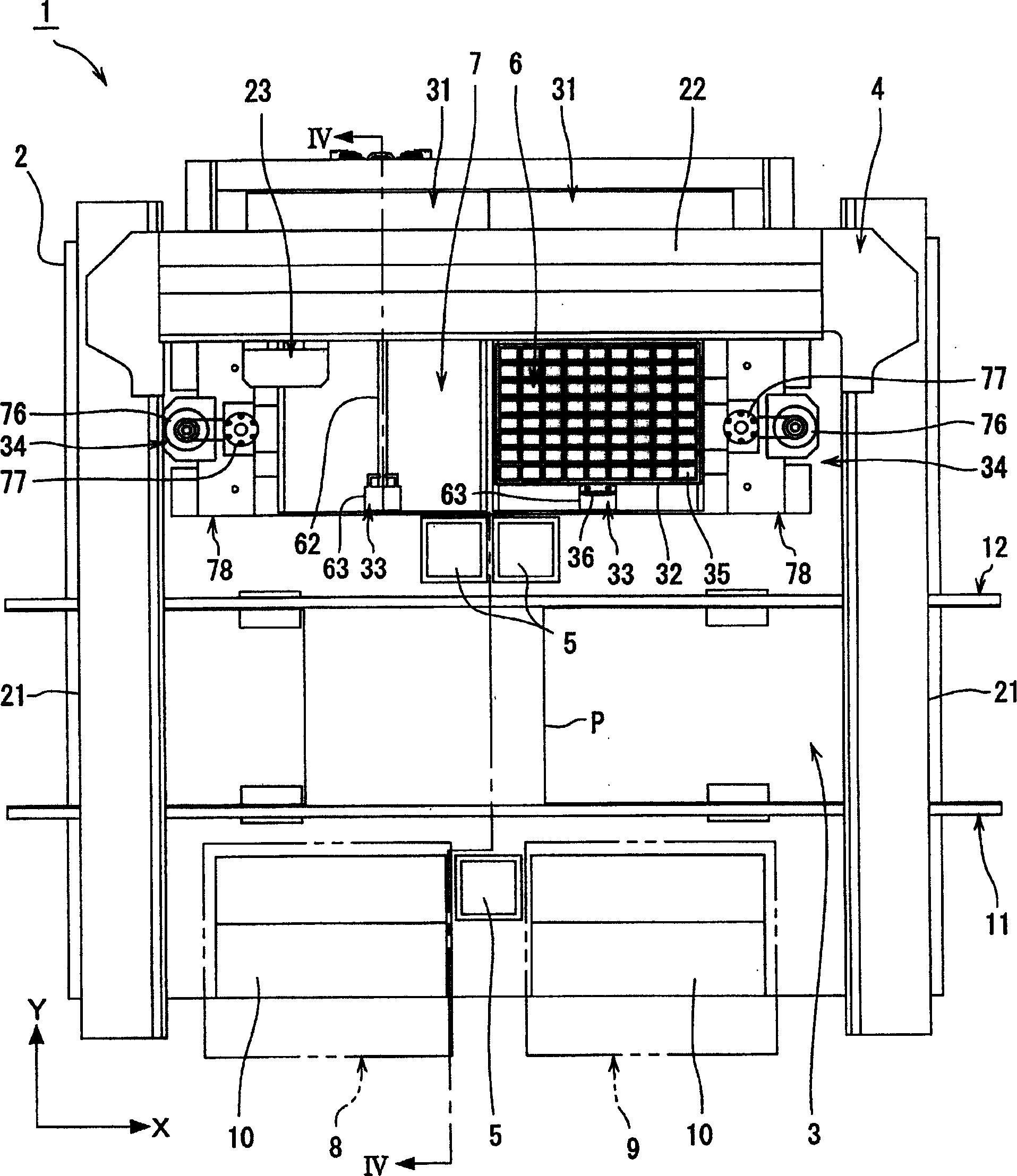

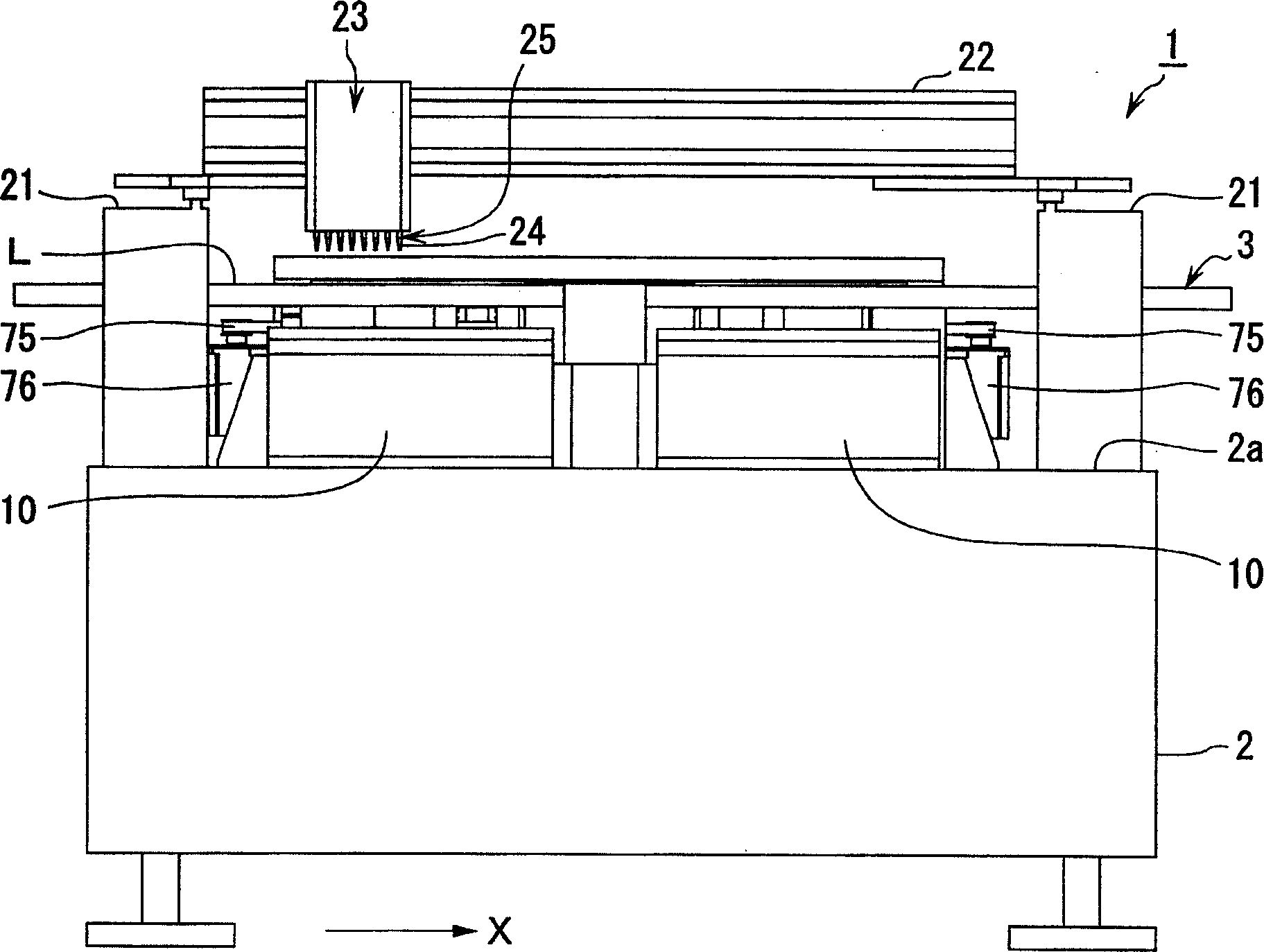

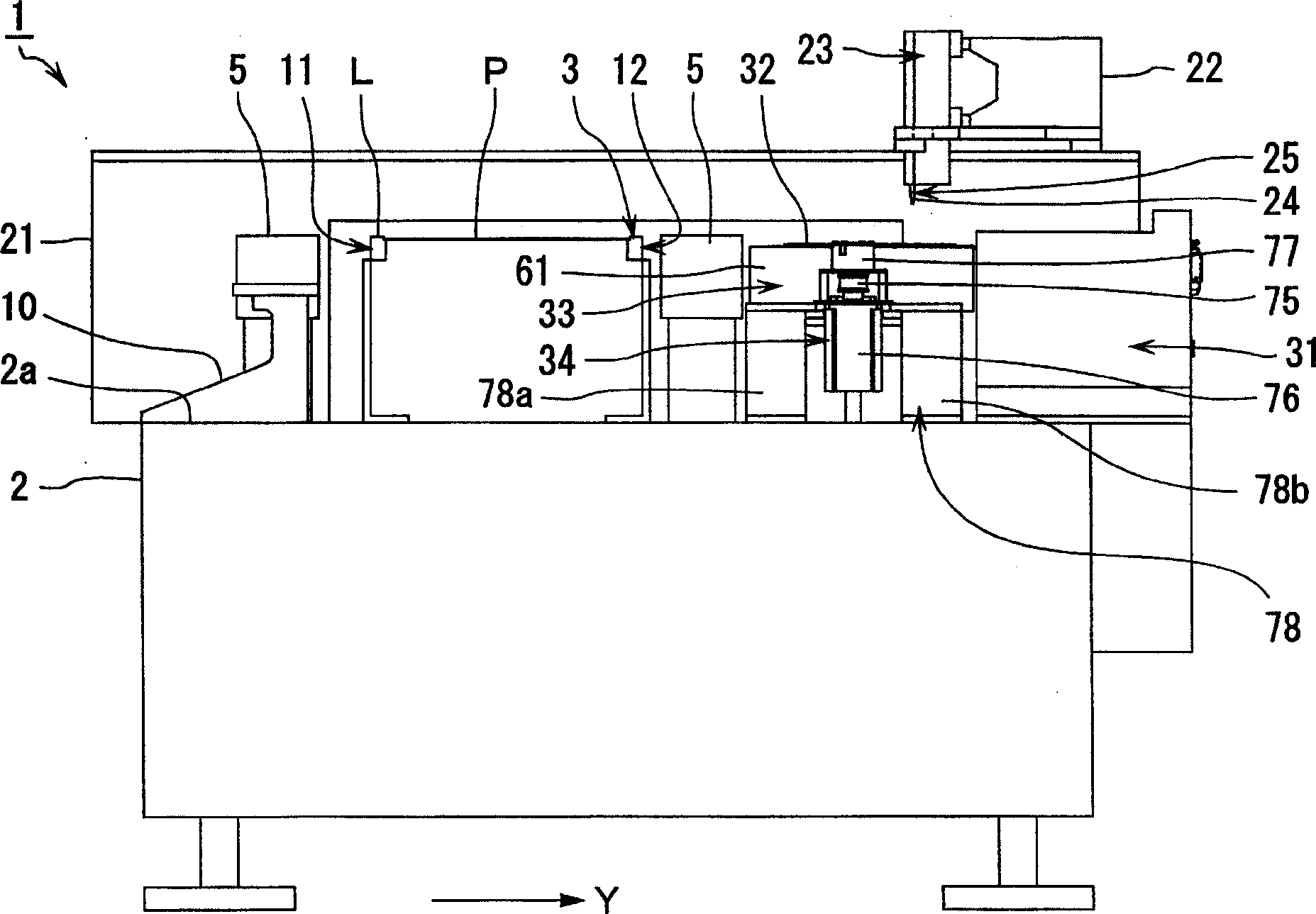

[0060] Use below Figure 1 to Figure 14 One embodiment of the surface mounting machine according to the present invention will be described in detail.

[0061] figure 1 It is a top view of the surface mounting machine involved in the present invention; figure 2 is its front view; image 3 is its side view; Figure 4 is along figure 1 Sectional view of line IV-IV in ; Figure 5 is a perspective view showing the entire surface mounter according to the present invention; Figure 6 is the top view of the tray feeder; Figure 7 is a perspective view of the tray feeder; Figure 8 is an enlarged perspective view showing the upper end of the lifting device; Figure 9 is a perspective view of the pallet entry and exit device; Figure 10 It is a perspective view of the surface mount machine viewed from the back.

[0062] Figure 11 It is a figure showing the lid part when closing the opening and closing member, Figure 11 (A) is a plan view rotated 180° so that the rear sid...

no. 2 Embodiment approach

[0145] Pan feeders can use Figure 17 and Figure 18 structure shown.

[0146] Figure 17 It is a perspective view which shows another embodiment of a pan feeder, Figure 18 It is an enlarged perspective view showing the upper end portion of the lifting device. In these figures, with the above Figure 1 to Figure 16 The same or equivalent parts described in are labeled with the same reference numerals and detailed descriptions are appropriately omitted.

[0147] Figure 17 and Figure 18 The lifter 34 shown is connected to the upper end of the ball screw shaft 72 via a coupling 91 so as to be coaxial with the drive motor 76 . The drive motor 76 is housed in a case 92 and fixed to the support base 78 via the case 92 . An electromagnetic brake 77 for restricting the rotation of the ball screw shaft 72 is provided in the housing 92 . This electromagnetic brake 77 is the same as the electromagnetic brake used in the first embodiment.

[0148] By configuring the elevating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com