Method for guiding band into a rewinder and rewinder thereof

A technology of rewinding machine and strip, applied in the field of rewinding machine, can solve problems such as difficulty in automatic operation and errors, and achieve the effect of simplifying the threading and guiding of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

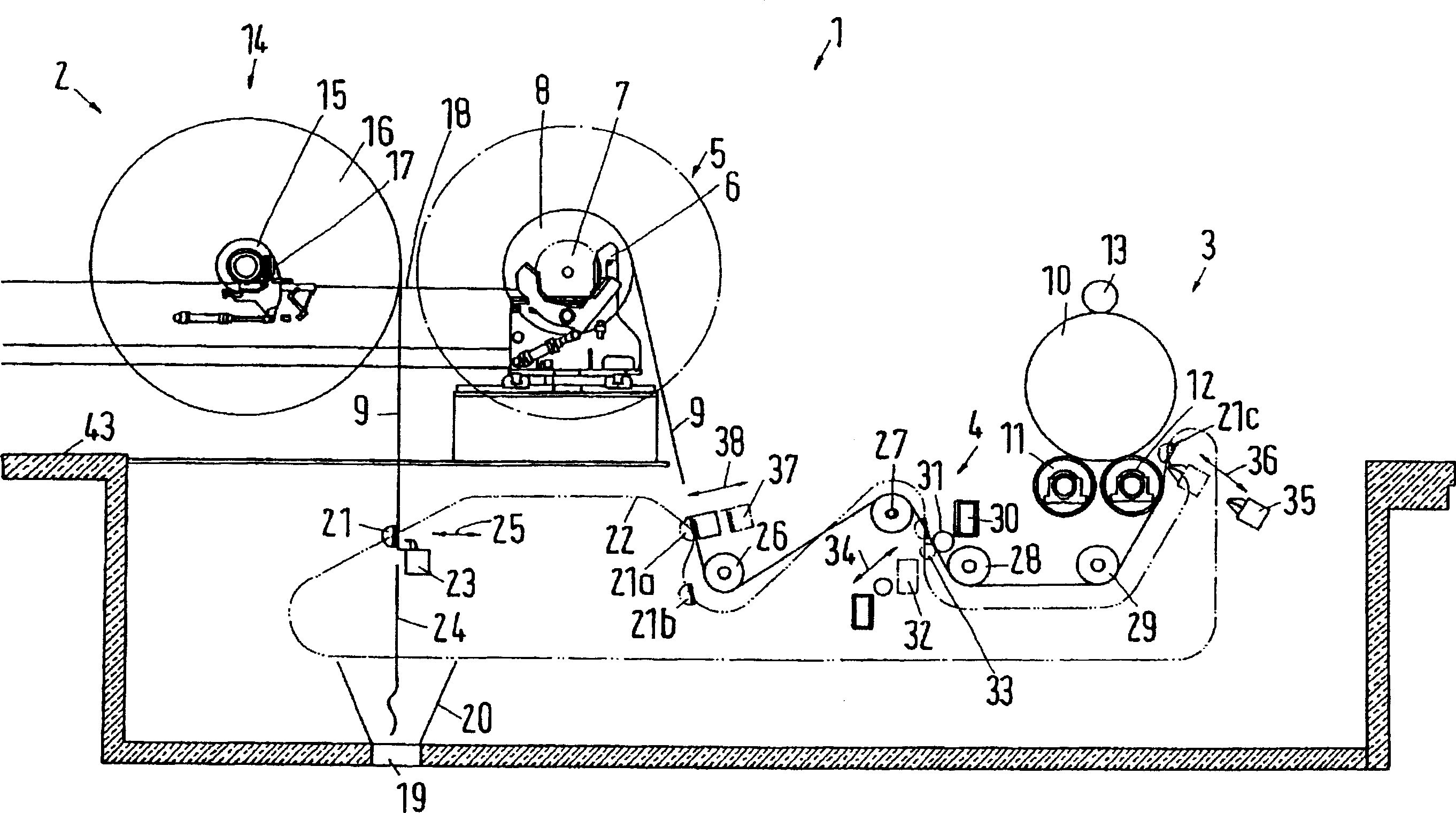

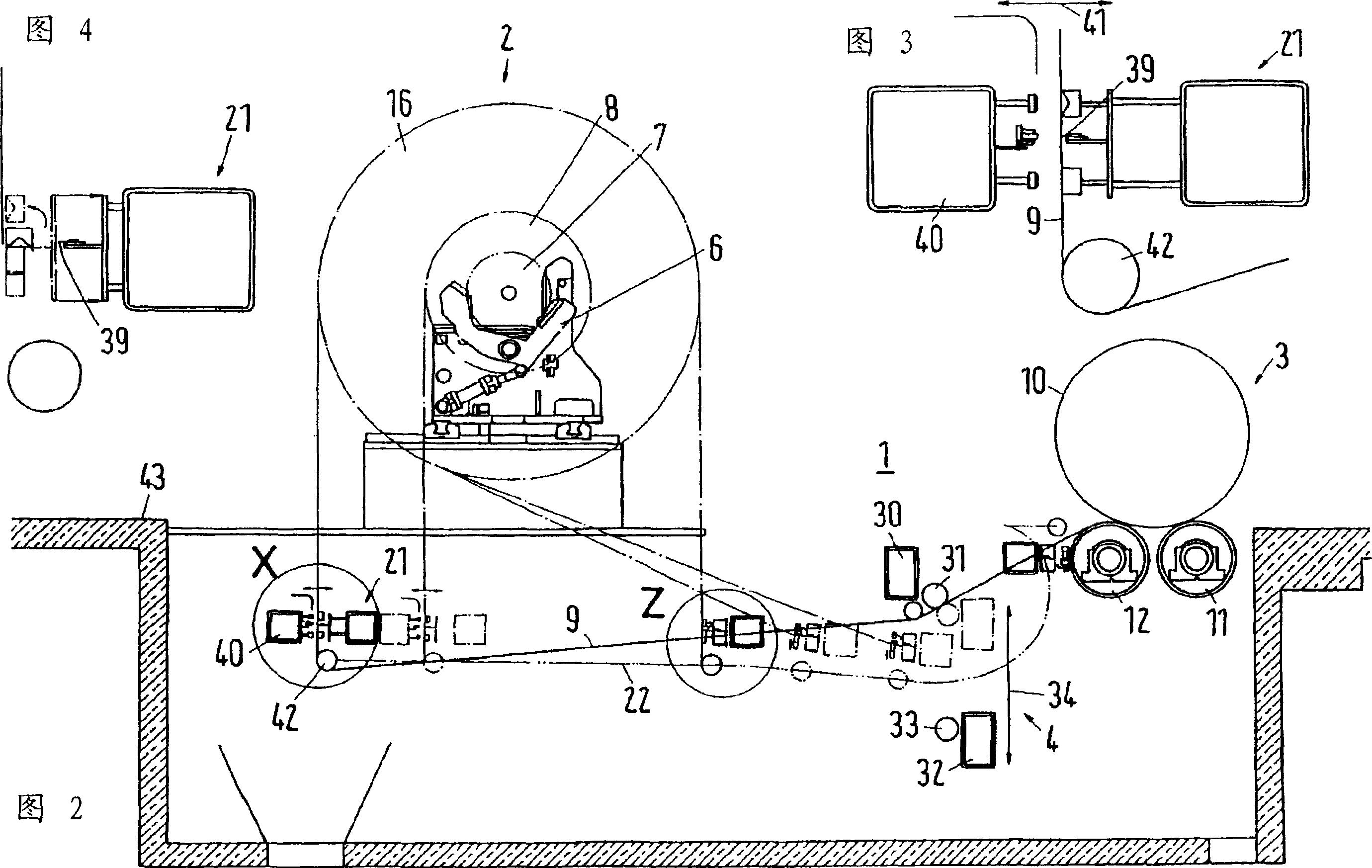

[0036] figure 1 is a schematic diagram of a rewinder 1 with an unwinding station 2 and a winding station 3 . The slitter 4 is arranged between the unwinding station 2 and the winding station 3 .

[0037] There is an unfolding position 5 in the unfolding station. In the unfolded position 5 there is an unfolding bearing 6 on which a reel 7 is rotatably mounted. The original tape roll 8 is wound on the reel 7, from figure 1 Part of it can also be seen. The strip 9 is drawn from the original coil 8, which may also be called a "jumbo coil". The strip 9 is cut into a plurality of strip sections at the slitter 4 and wound into a plurality of rolls 10 at the winding station 3, since these rolls 10 are arranged in a direction perpendicular to the plane of the drawing. pick one, so in figure 1 Only one roll is visible in .

[0038] The unrolling bearing 6 is suitable for relatively high speed operation. For example, the strip 9 may be withdrawn at a speed of 2000 to 3000 m / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com