Fabric presser of sewing machine

A sewing machine and medium pressure technology, which is applied to the sewing machine control device, sewing machine components, and program-controlled sewing machines, etc., can solve the problems such as the inability to maintain the height of the intermediate presser foot, the large stroke of the intermediate presser foot, and the change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]

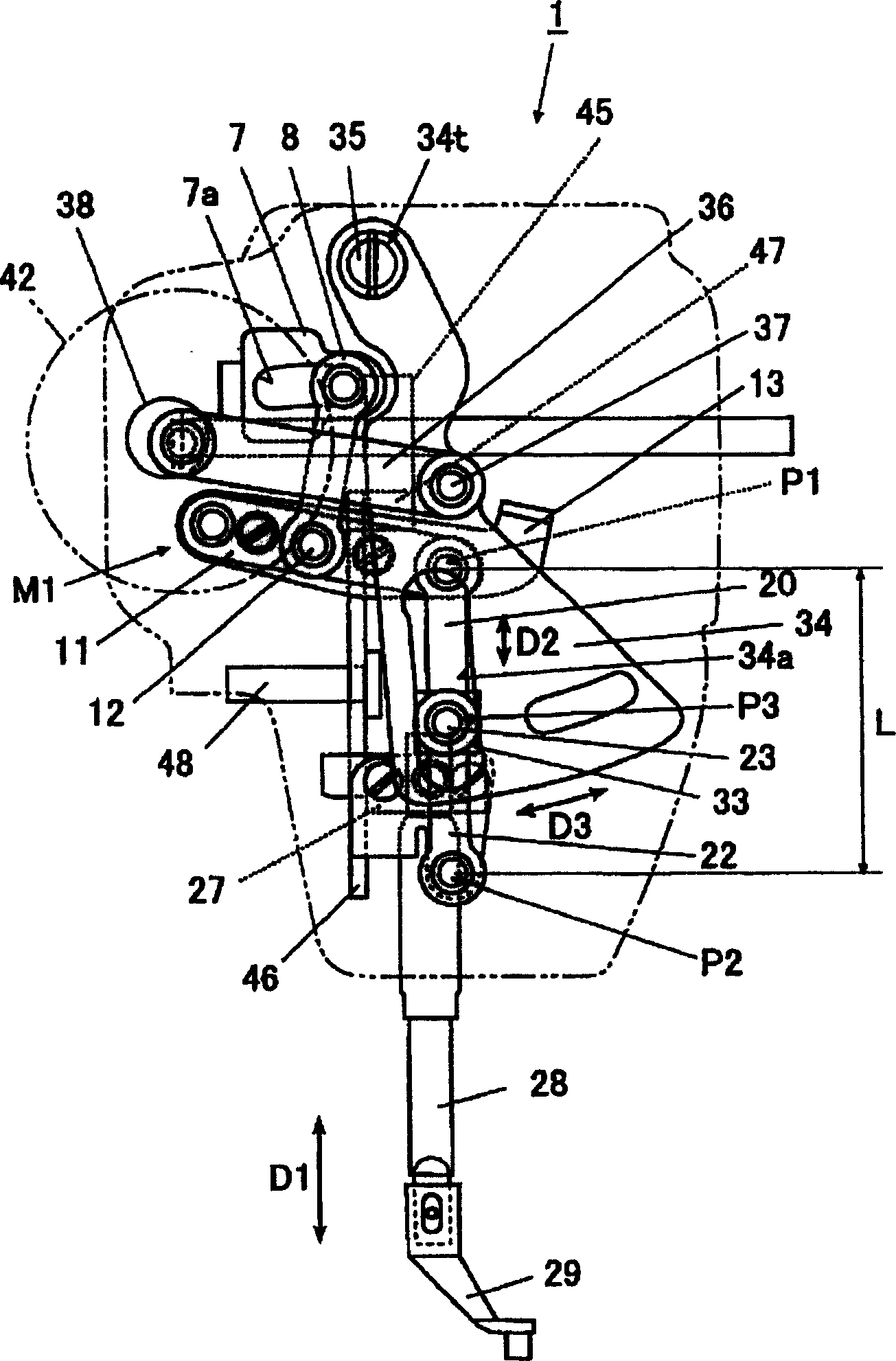

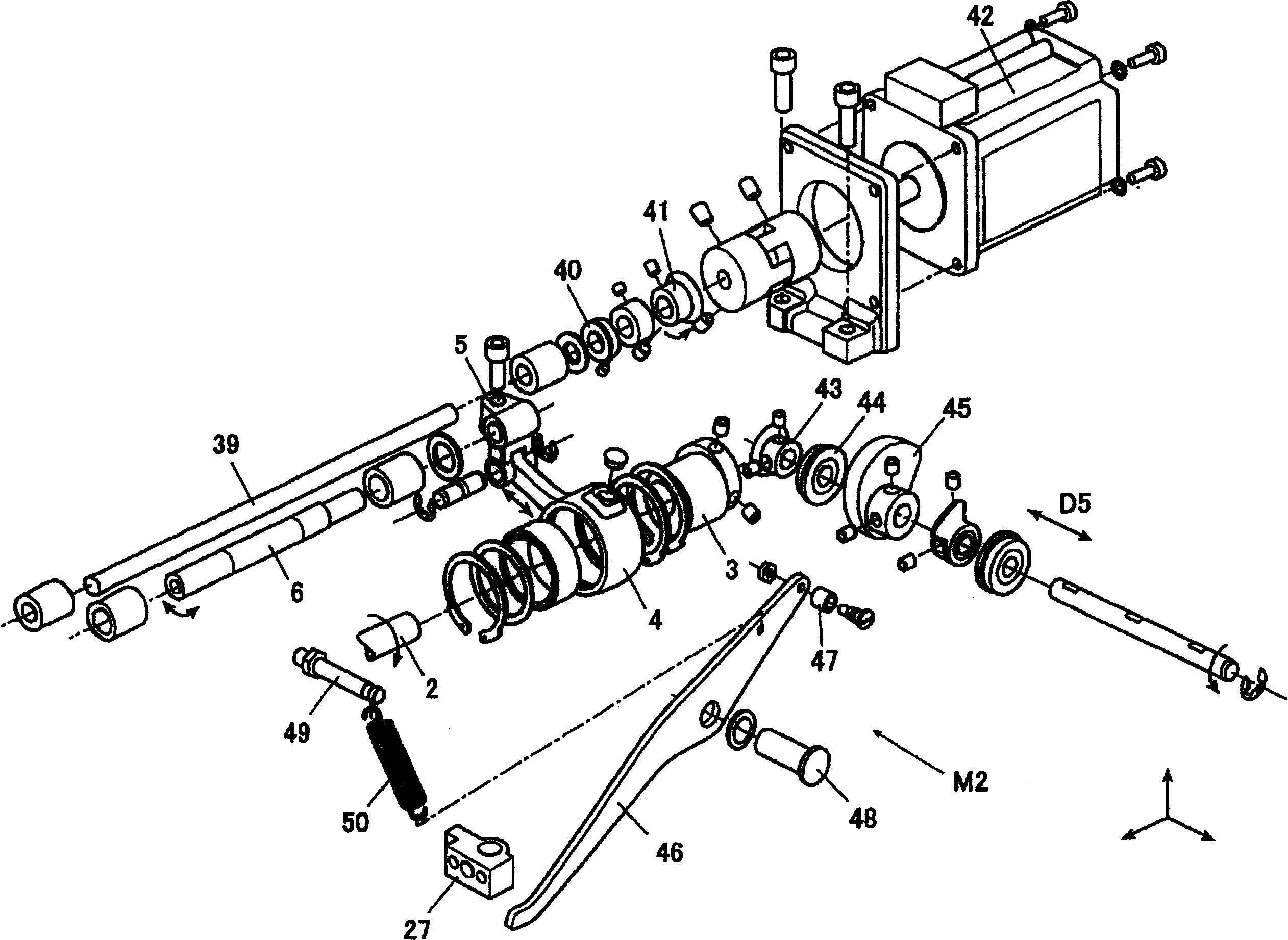

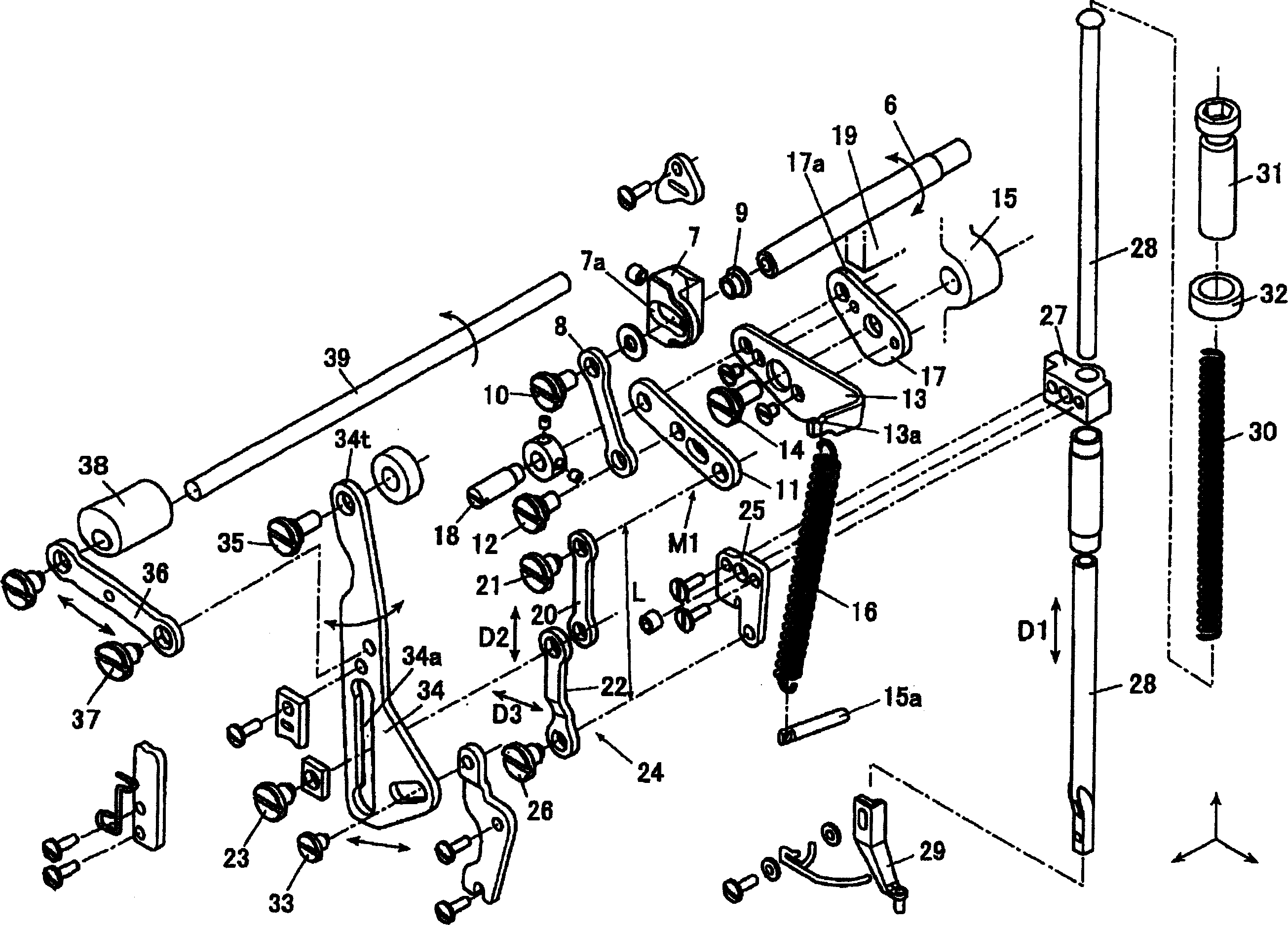

[0054] Such as Figure 1 ~ Figure 3 As shown, the middle cloth pressing device 1 is arranged on the upper shaft 2, and the upper shaft 2 drives the needle bar provided with the machine needle at the front end to move in the up and down direction. The eccentric cam 3 is fixed on the upper shaft 2, and the connecting link 4 is connected on the eccentric cam 3. The rocking shaft abutment 5 is connected to the connecting rod 4 , and one end of the rocking shaft 6 is connected to the rocking shaft abutment 5 .

[0055] At the other end of the rocking shaft 6, a base end portion of an intermediate presser adjusting arm 7 for adjusting the movement amount of the intermediate presser in the vertical direction D1 is fixed. A grooved cam 7 a is formed on the intermediate presser adjusting arm 7 . The grooved cam 7a is an arc-shaped long hole, and the desired position of the grooved cam 7a and one end of the first link 8 are rotatably fixed by the adjusting nut 9 and the seg...

Embodiment 2

[0094]

[0095] The intermediate cloth pressing device 1G of the second embodiment can retract the intermediate presser foot 29 to the retracted height position P5 with a smaller force than that of the first embodiment. In addition, in the middle cloth pressing device 1G, the moving link 36 is changed to a moving mechanism 51, and this moving mechanism 51 also functions as a releasing mechanism for releasing the elastic force applied to the second link 11 by the coil spring 16. Regarding other parts , since they have the same configuration as in Embodiment 1, they are marked with the same symbols and descriptions thereof are omitted.

[0096] Such as Figure 9 As shown, the moving mechanism 51 has a rotating link 52 whose one end is connected to the movable shaft 39 , and an adjustment mechanism whose one end is connected to the other end of the rotating link 52 and the other end is connected to the guide member 55 . Connecting rod 53.

[0097] The adjustment link 53 has o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com