Retraction type safety syringe

A technology for safe injection and injection needles, which is applied in the field of retractable safe injection syringes, and can solve the problems of not having to replace the injection needles, being unable to achieve a wide range of applications, and having no safe retraction and storage of the injection needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

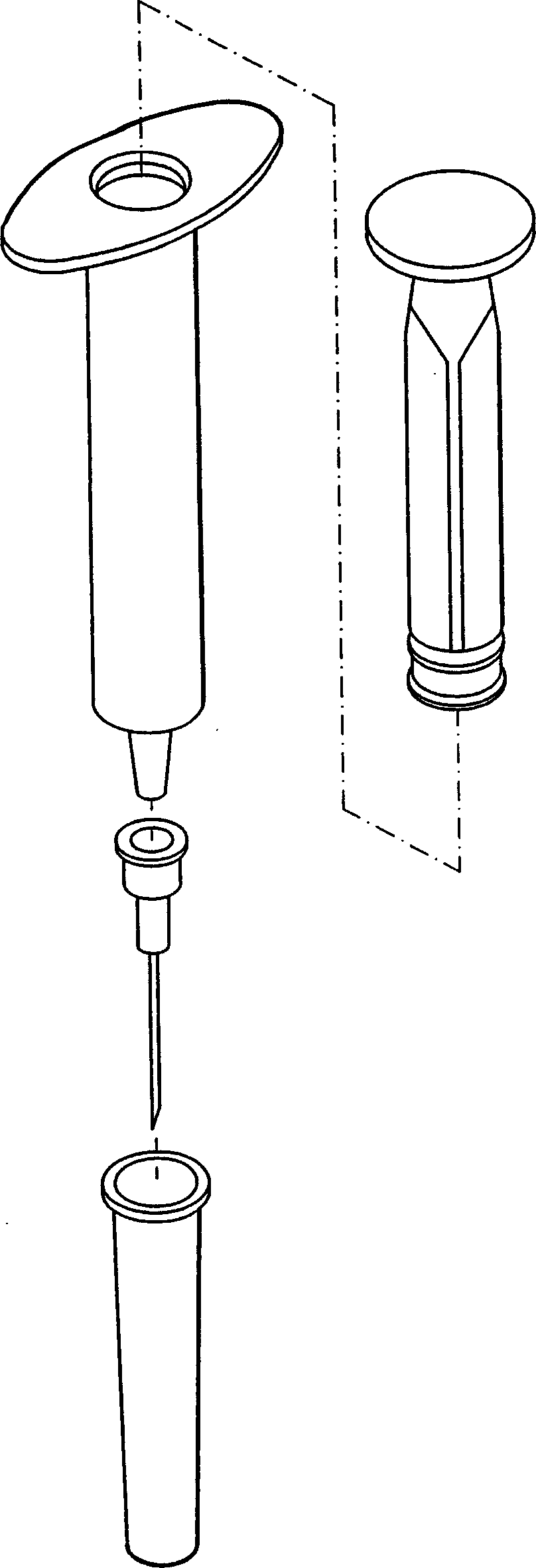

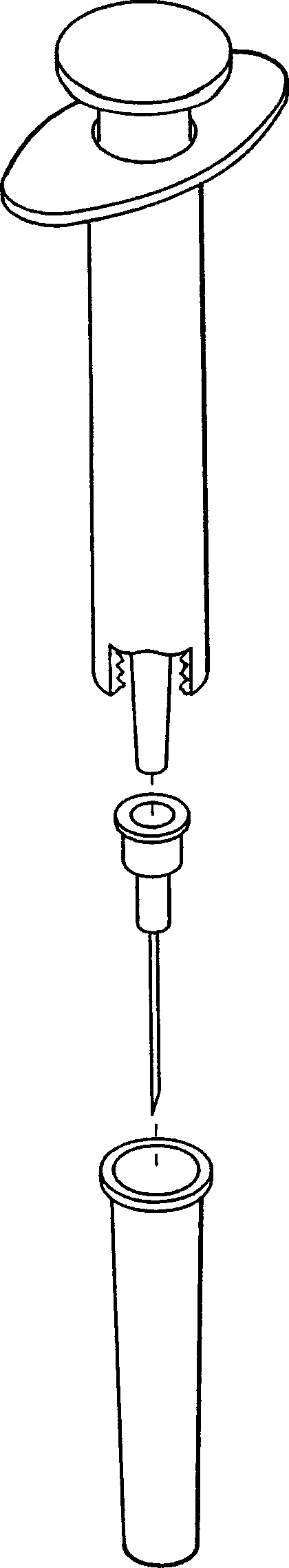

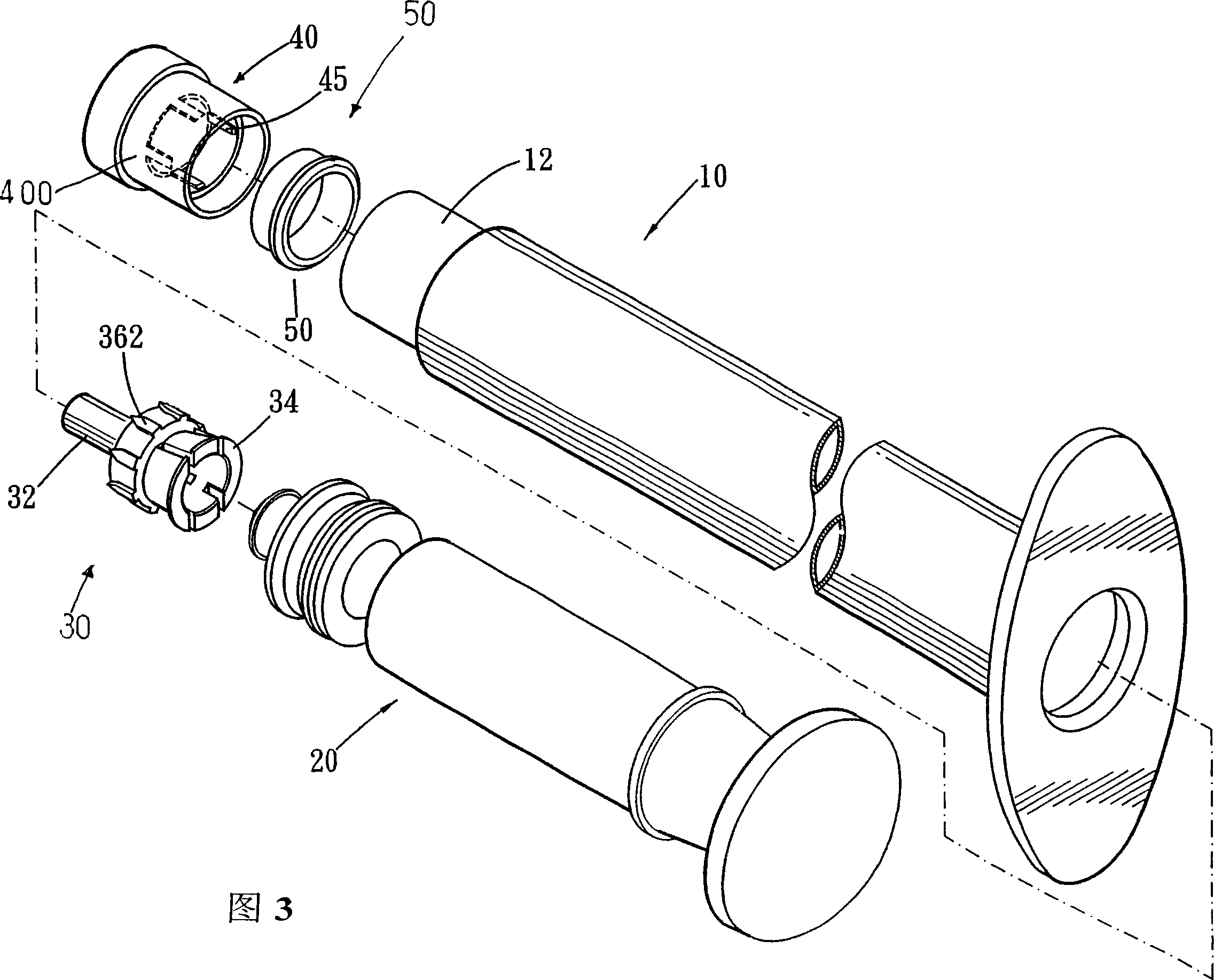

[0027] Please refer to Figures 3 to 6, the retractable safety injection syringe of the present invention mainly includes an outer cylinder 10, a cap sleeve 40, a connecting seat 30, a push rod 20 and an injection needle 90, wherein the outer cylinder 10 is a hollow tube, and the inner cavity of the outer cylinder 10 protrudes radially near the front end to form a protruding ring 13 , so that the inner cavity of the outer cylinder 10 forms a front cavity 12 and a rear cavity 14 .

[0028] The cover sleeve 40 is a tubular body formed by thermal fusion bonding of the cylinder body 400 and the sealing ring 50, and is tightly fitted in the front chamber 12; The anterior cavity 12 of the front cavity is an interference fit for fixing the cap sleeve 40; the sealing ring 50 is a tubular body formed from an elastic material (such as rubber), and the outer circumference of the sealing ring 50 is connected to the outer cylinder 10 The close fit of the inner wall of the front chamber 12 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com