Optical disk device

An optical disc device and optical technology, which is applied to the configuration/installation of heads, recording/reproducing by optical methods, instruments, etc., can solve the problems of increasing operating hours, affecting the simplification of assembly, etc., so as to reduce operating hours and prevent falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

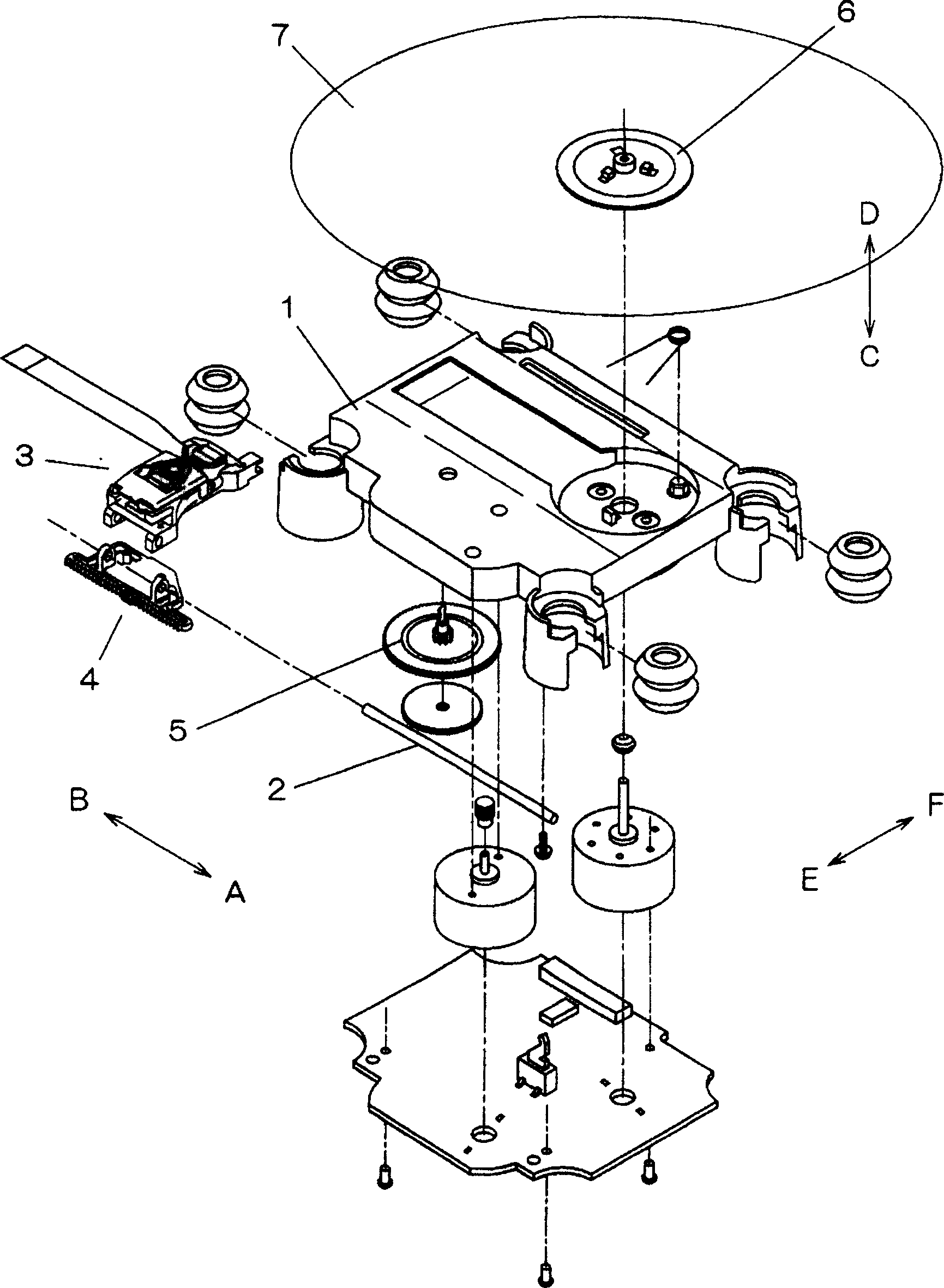

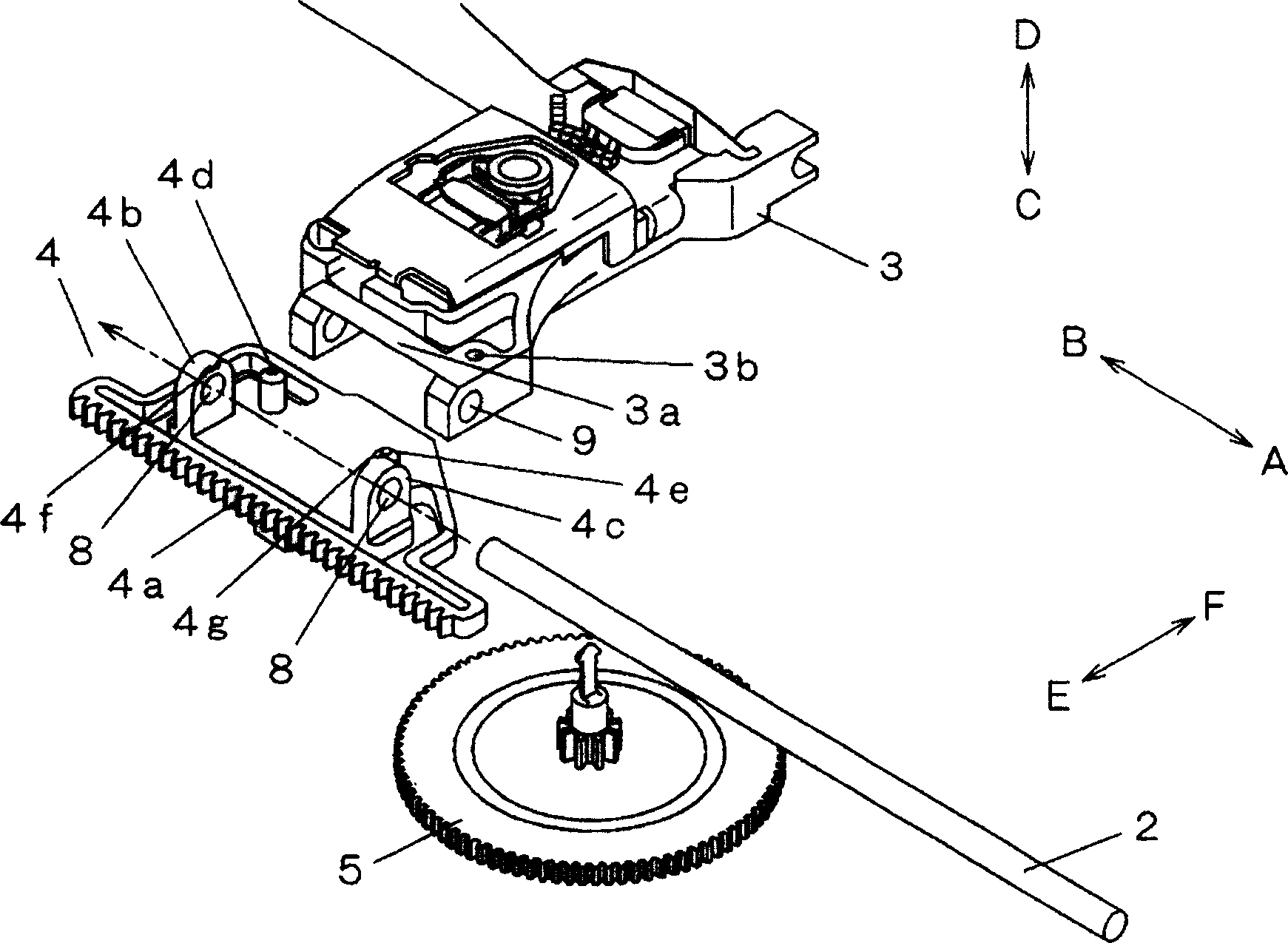

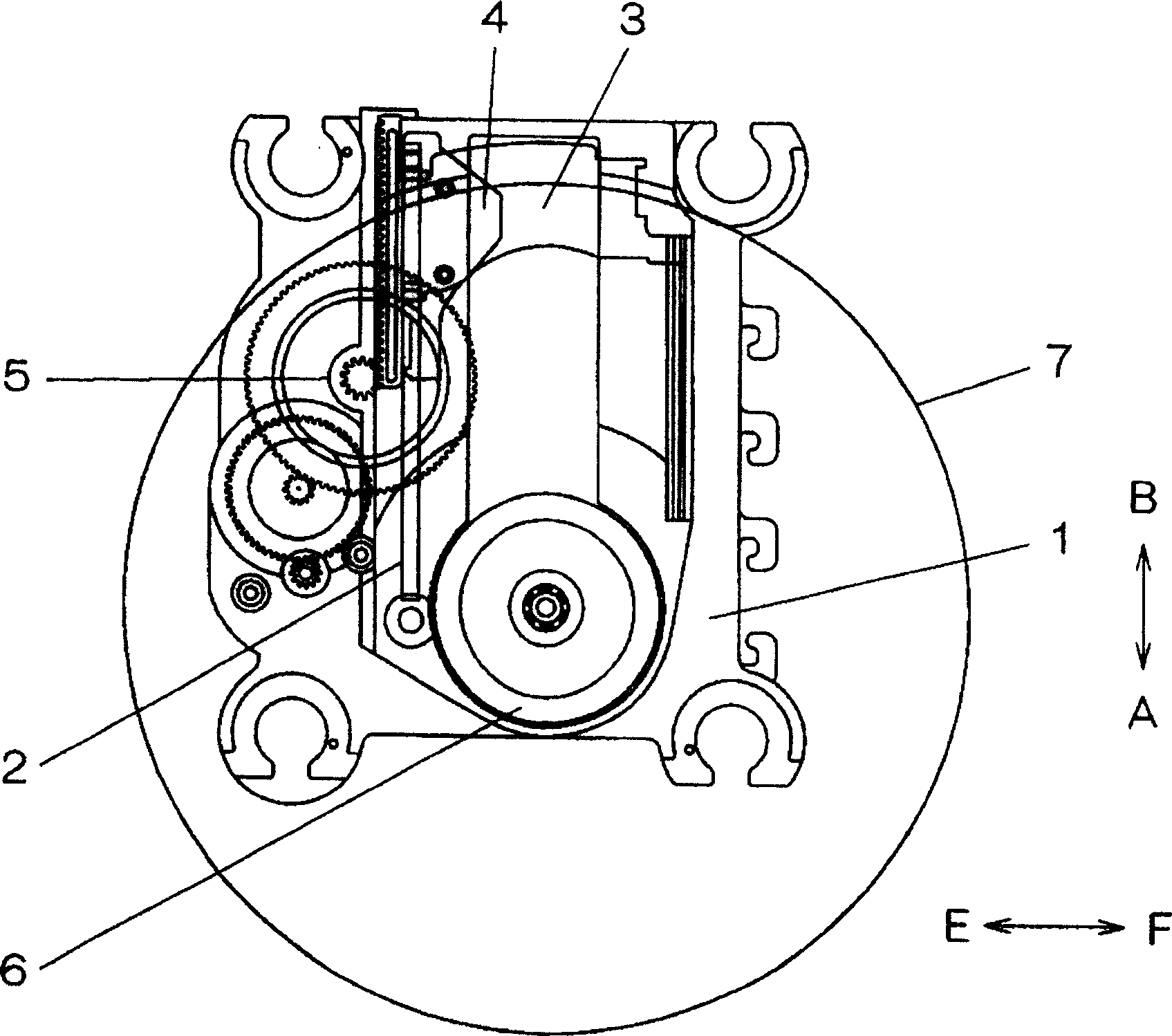

[0022] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an exploded perspective view of the part structure in the device embodiment of the present invention, figure 2 yes figure 1 A zoomed-in perspective view of the vicinity of the optical pickup in the middle, image 3 is a plan view after the device is assembled in the present invention, Figure 4 is a plan view near the turntable in the above embodiment, Figure 5 From Figure 4 The side view indicated by the arrow Z direction in the middle, Figure 6 From Figure 4 The side view shown in the arrow Y direction in the middle, in order to better understand the above description, shows the section near the optical pickup 3 and the rack 4 ( Figure 4 X-X section).

[0023]In the figure, 7 is a recording medium for recording various signals, that is, a disk, 3 is an optical pickup for recording and reproducing signals on the disk 7, and is composed of a lens and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com