Nano bullet proof tyre and its manufacturing method

A technology for bulletproof tires and production methods, applied to tire parts, tires, non-pneumatic tires, etc., can solve the problems of high material cost, poor heat resistance, and small application range, and achieve long service life and good heat resistance , is beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

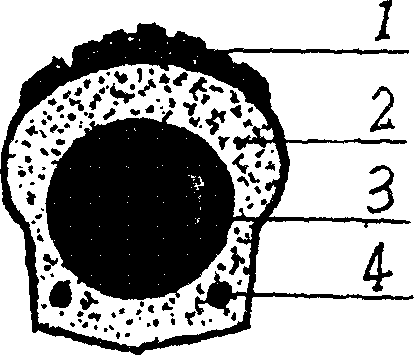

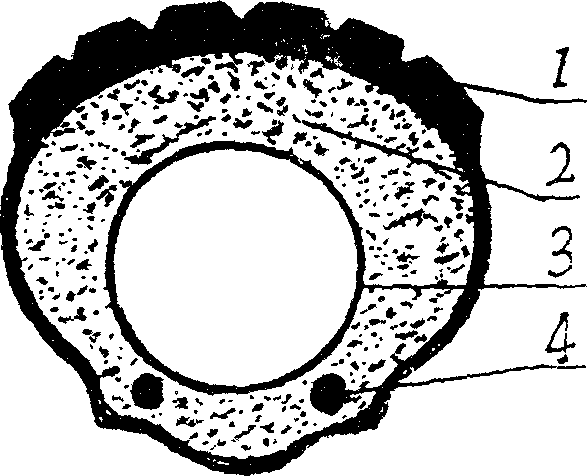

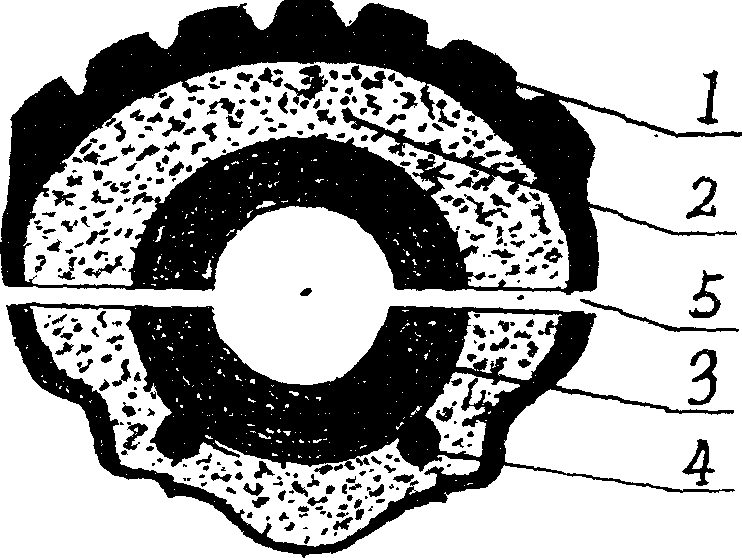

[0016] Such as Figure 1 to Figure 8 As shown, first take the special inner tube 3 and bead 4 and set them in the tire mold on the centrifugal molding machine. The bead of forklift, battery car, agricultural vehicle, automobile and other motor vehicle tires can be made of steel wire material, and the bead is set on the inner side of the upper and lower molds. Each tire is preferably 2, and the inner tube can be used. Rubber tires or leftovers in production are crushed and processed, and can also be made of other materials. The shape, size, carcass thickness, hardness and number of strips can be determined according to the needs of different tires. The inner tube and bead are set After finishing, close the mold, start the centrifugal molding machine, and then according to different tires, use one-step polyurethane raw materials of one formula for centrifugal molding or use two different formulas of polyurethane raw materials for two-step pouring centrifugal molding, baby carriag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com