Non-pneumatic tire

A technology of non-pneumatic tires and tread parts, applied in the field of rubber tires, can solve the problems affecting riding comfort, control stability, untargeted performance, weakening the strength of the carcass, etc., to ensure riding comfort and control stability. performance, improved comfort and handling stability, reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the drawings and specific embodiments.

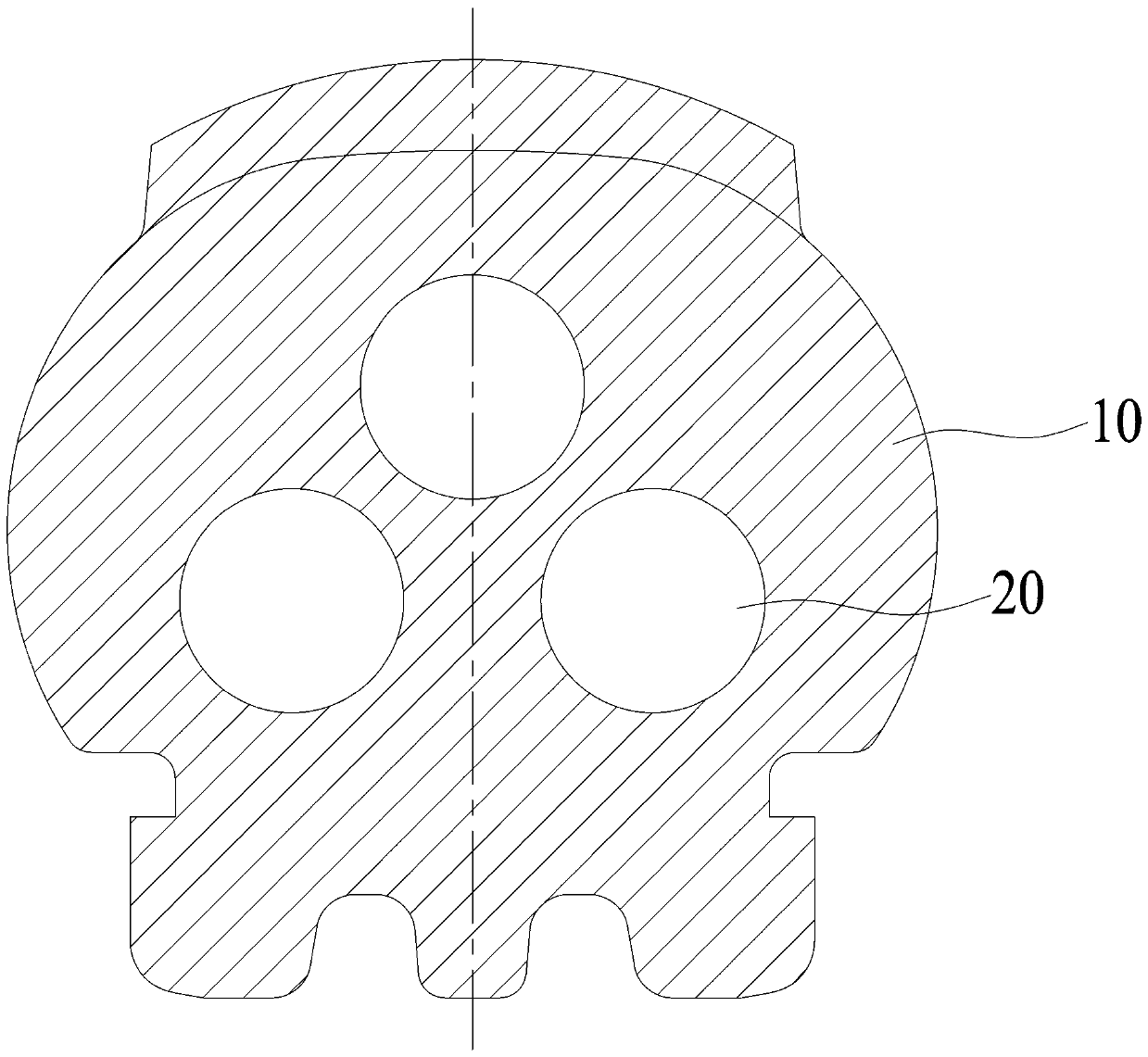

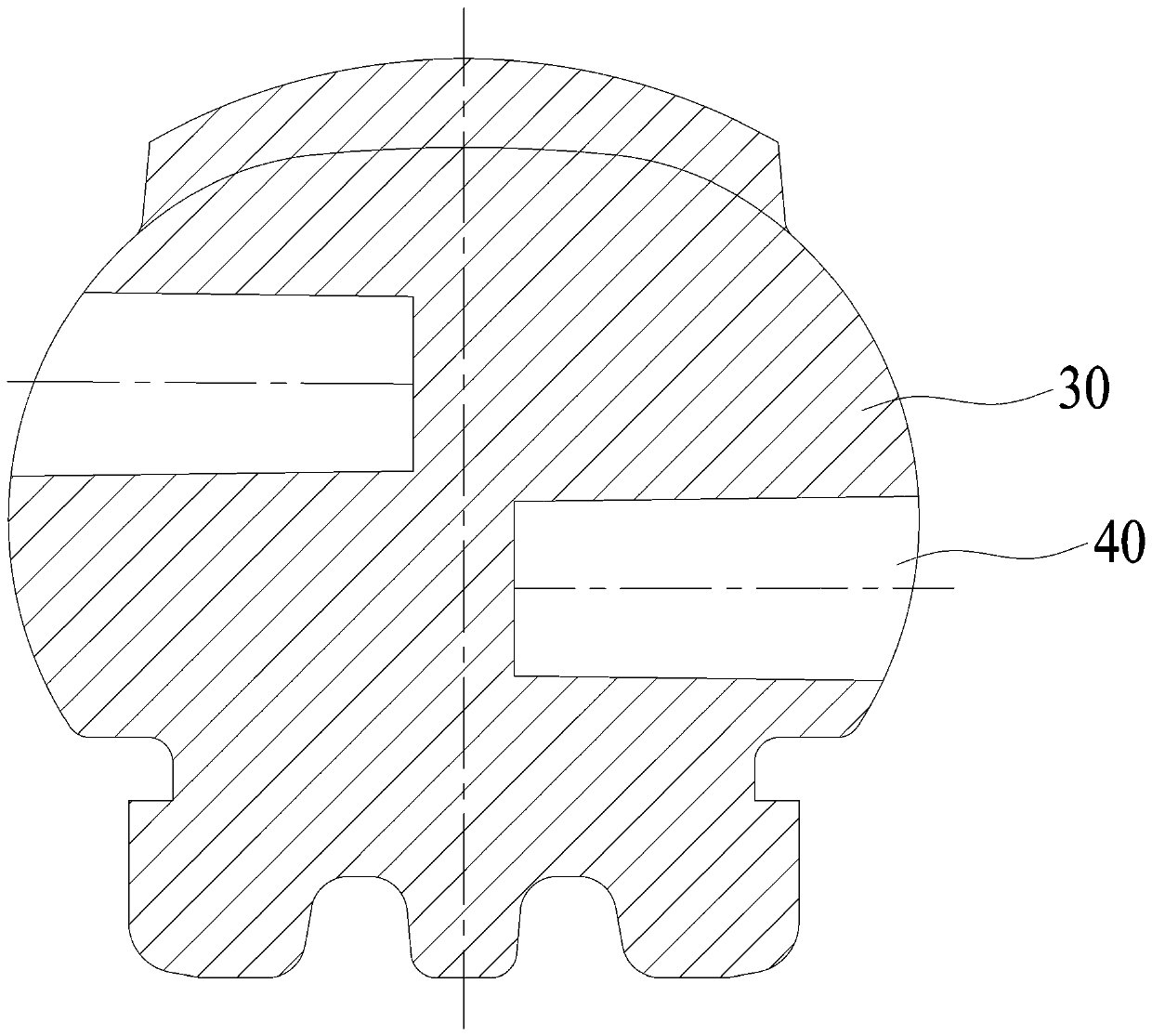

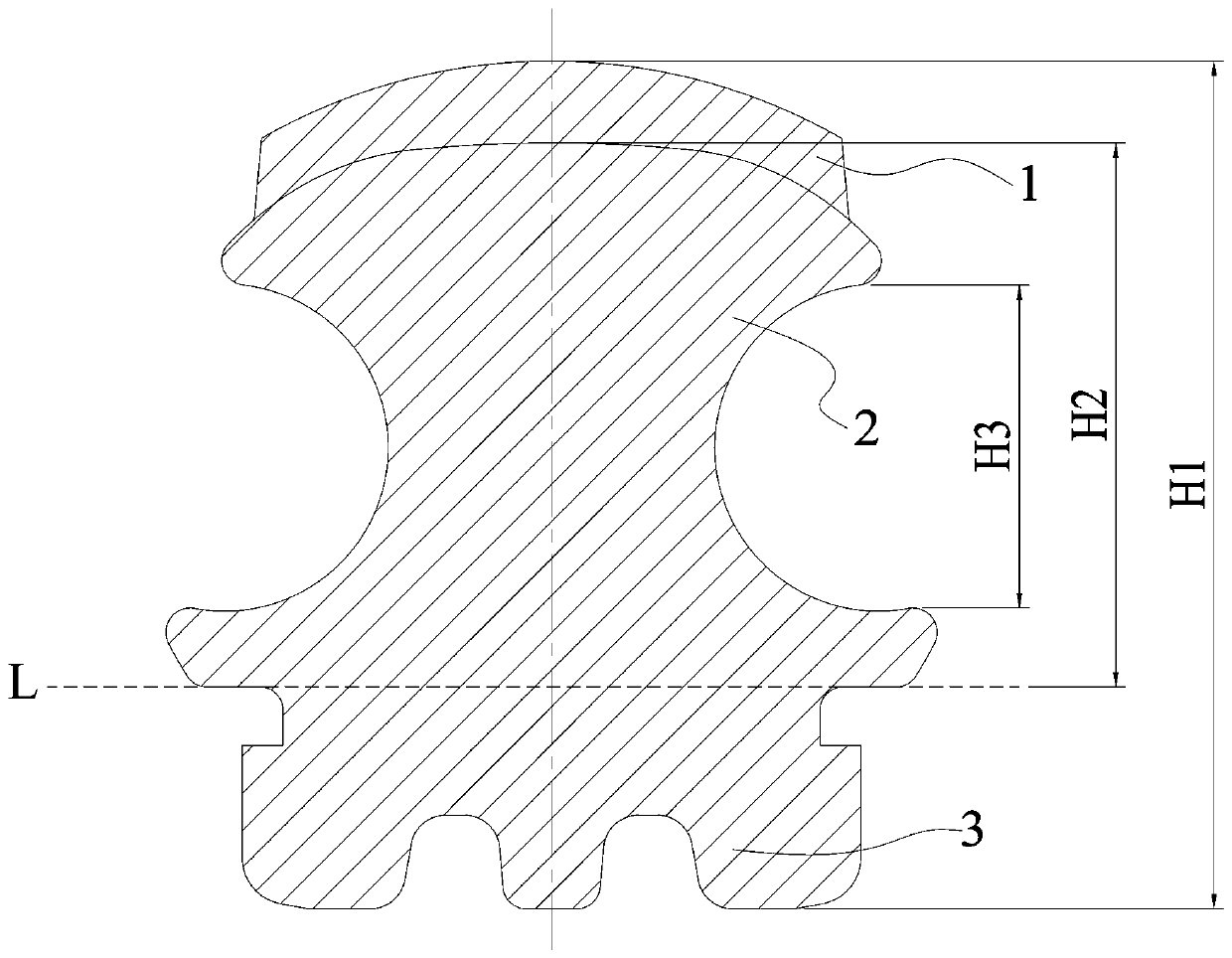

[0043] See Figure 3 to Figure 9 As shown, the non-pneumatic tire disclosed in the present invention is made of rubber material, such as image 3 As shown, the vertical direction is defined as the tire radial direction, and the lateral direction is defined as the tire axial direction; Figure 5 As shown, CL stands for the center line of the tread, the left side of the tread center line CL is defined as the lower tire profile, and the right side of the tread center line CL is defined as the upper tire profile.

[0044] Such as image 3 As shown, the non-pneumatic tire includes a tread section 1, a middle section 2 and a bottom section 3. The tread section 1 is configured with a pattern and is in contact with the ground. The bottom section 3 is mounted on the rim. The upper end of the middle section 2 is connected to the tread section 1 and the lower end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com