Hermetic compressor

A compressor, closed technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of reducing compressor efficiency, increasing compressor input power, etc., reducing sliding surface, improving Efficiency, the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

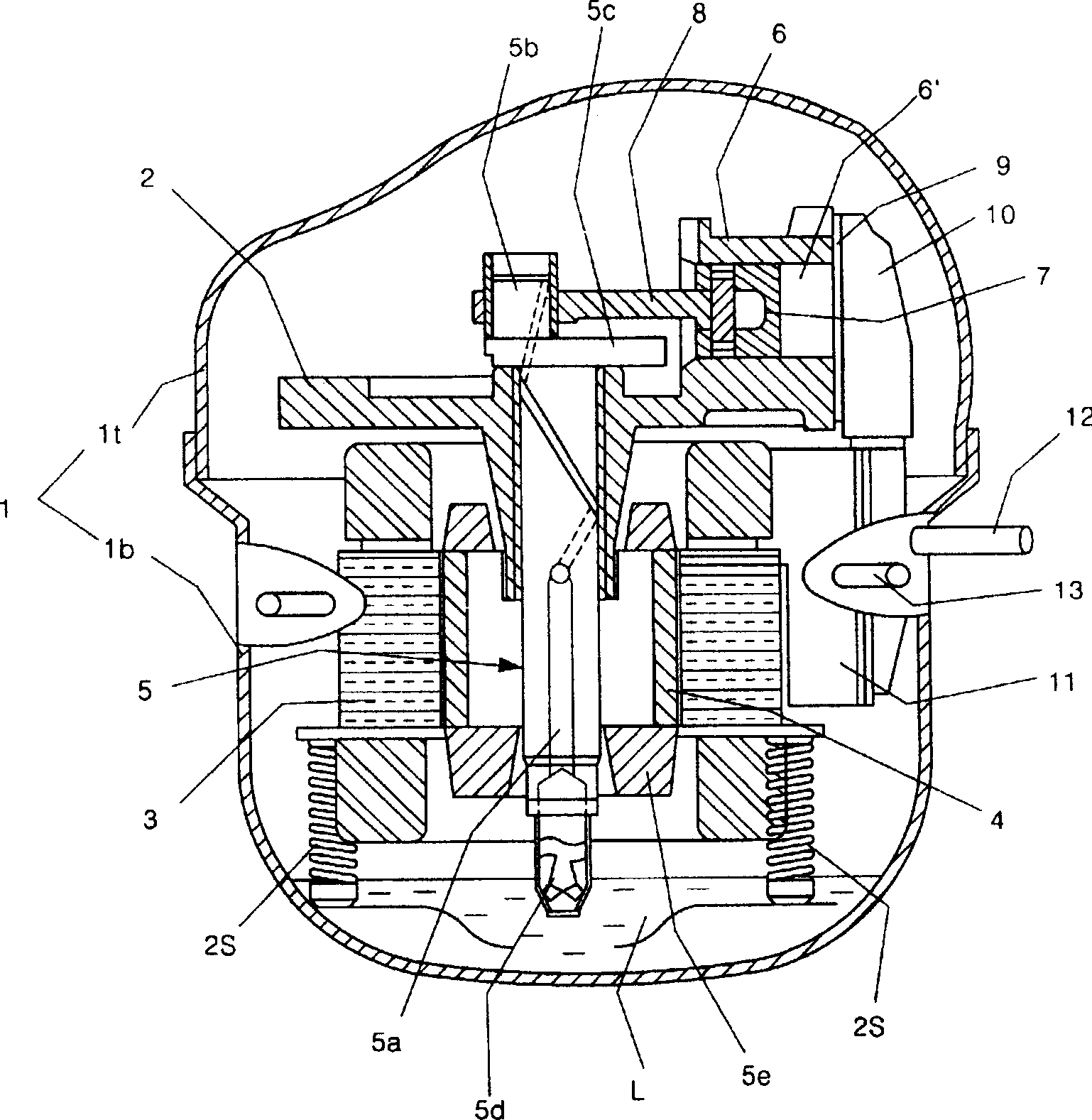

[0041] Embodiments of the hermetic compressor of the present invention will be described in detail below with reference to the accompanying drawings.

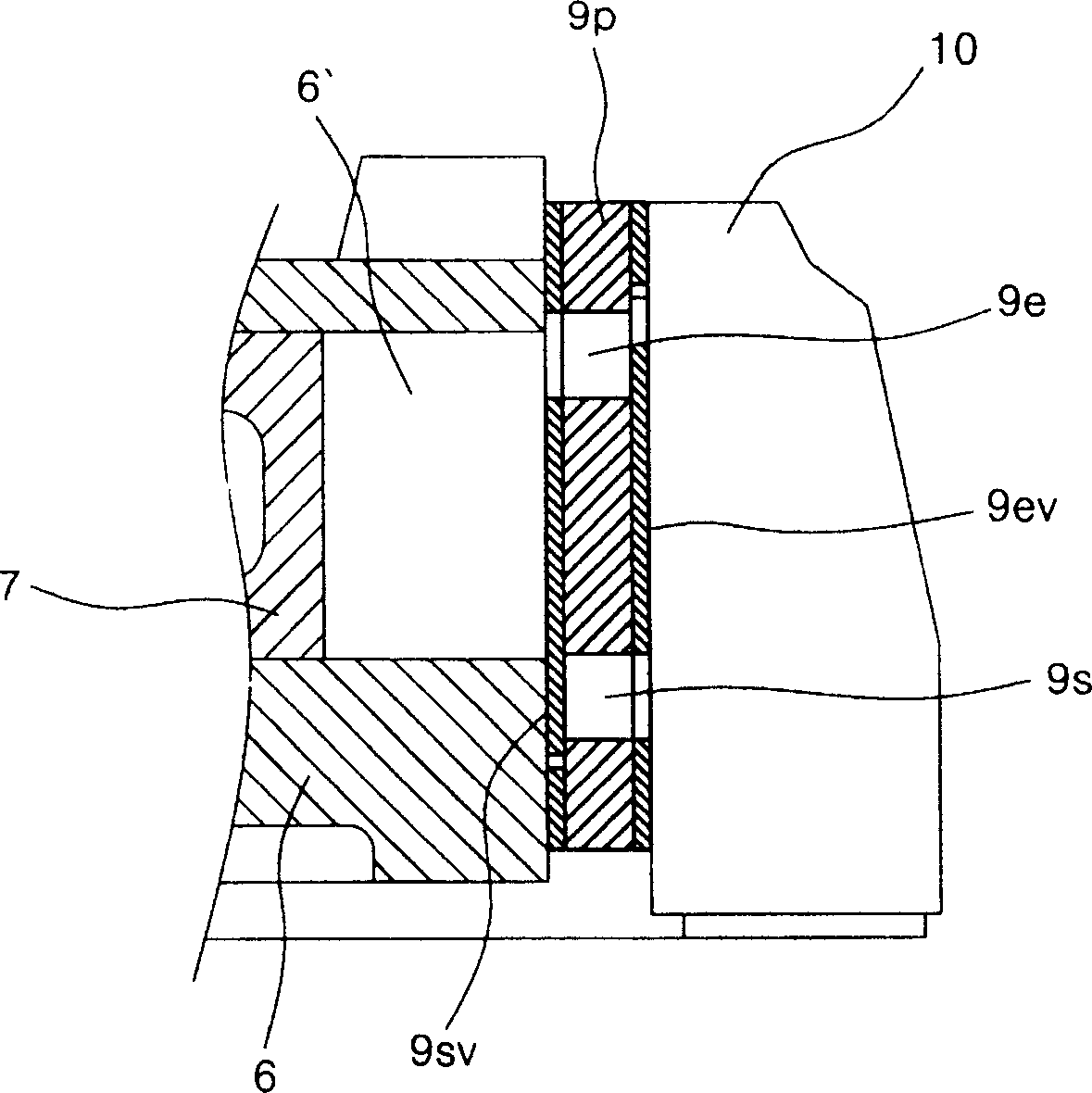

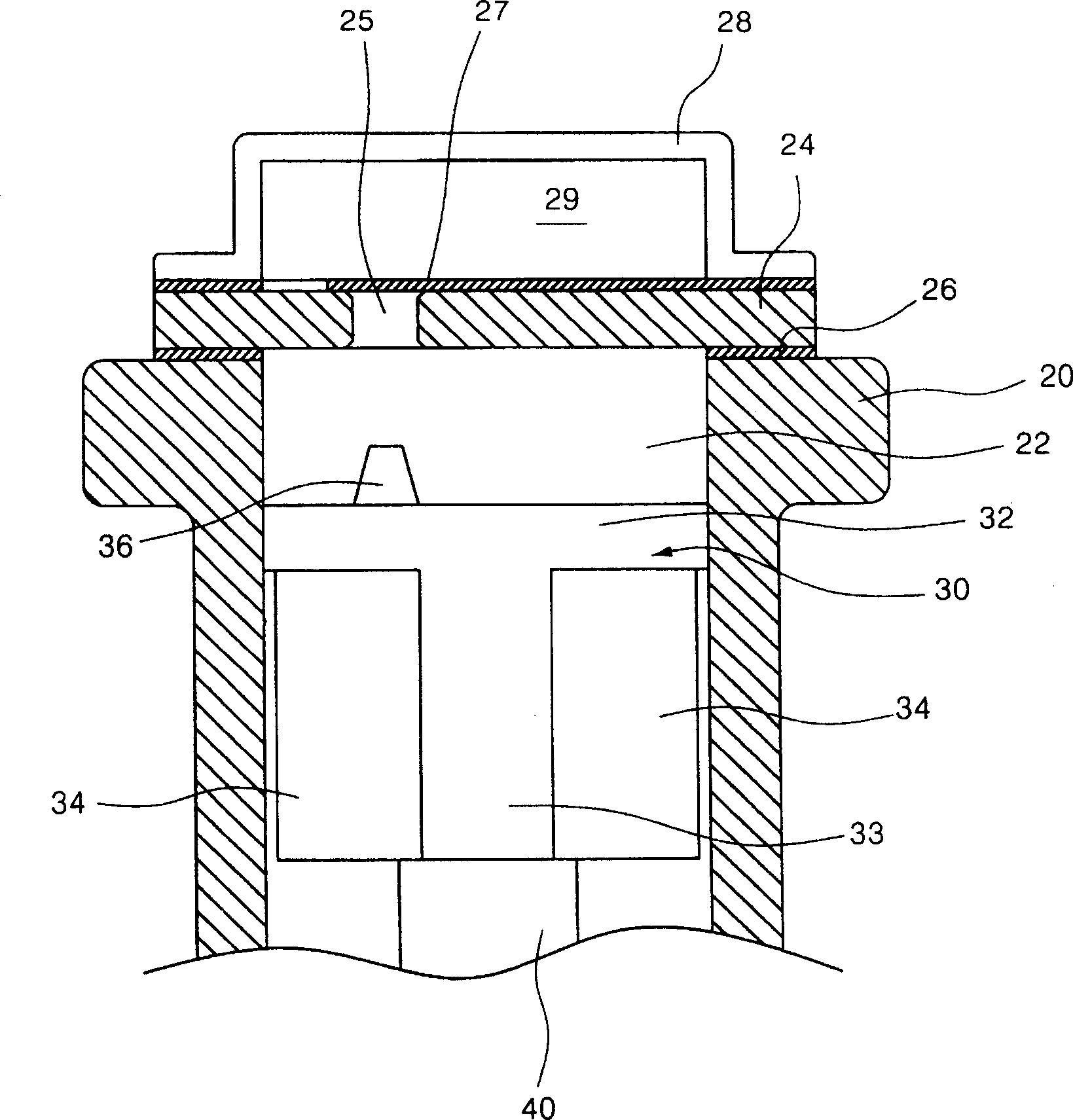

[0042] image 3 shows a cross-sectional view of the middle portion of an embodiment of the hermetic compressor of the present invention; Figure 4 shows the oblique view of the piston structure that constitutes the embodiment of the present invention; Figure 5 A cross-sectional view reflecting the structure of a piston constituting an embodiment of the present invention; Figure 6 A cross-sectional view showing the relationship between the volume space and the discharge hole of an embodiment of the present invention is shown in .

[0043] According to above-mentioned each figure, the frame that airtight container interior is provided with cylinder 20 is housed. A compression chamber 22 is formed through the front and back of the cylinder 20 . In order to block one side of the compression chamber 22, a valve groove 24 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com