Image forming device and controlling method thereof

A control method and image technology, applied in the direction of electrical recording technology using charge graphics, equipment and instruments using electrical recording technology using charge graphics, to achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0026] Figure 4 The schematic structure of the fixing device in the image forming apparatus of this embodiment is shown, Figure 5 A portion of the device is shown enlarged.

[0027] In this fixing device, a fixing film 4 as an example of a heat-conducting rotor is used, and a ceramic heater 1 as a heating element is embedded in a film guide 2 as a supporting member. The ceramic heater 1 is contacted and supported by the heater attachment surface 3 of the film guide device 2 .

[0028] In this embodiment, on an alumina substrate with a total length of 270mm, a width of 7.8mm, and a thickness of 1.0mm, the silver-palladium resistance heating element is printed in such a way that it becomes 24Ω in the center of the length direction to form a ceramic heating element of 219mm. Device 1. The inner diameter of the endless belt-shaped fixing film 4 heated by the ceramic heater 1 is 24mm, and the base material thickness of polyimide is about 40 μm, and an adhesive layer of about 5...

no. 2 approach

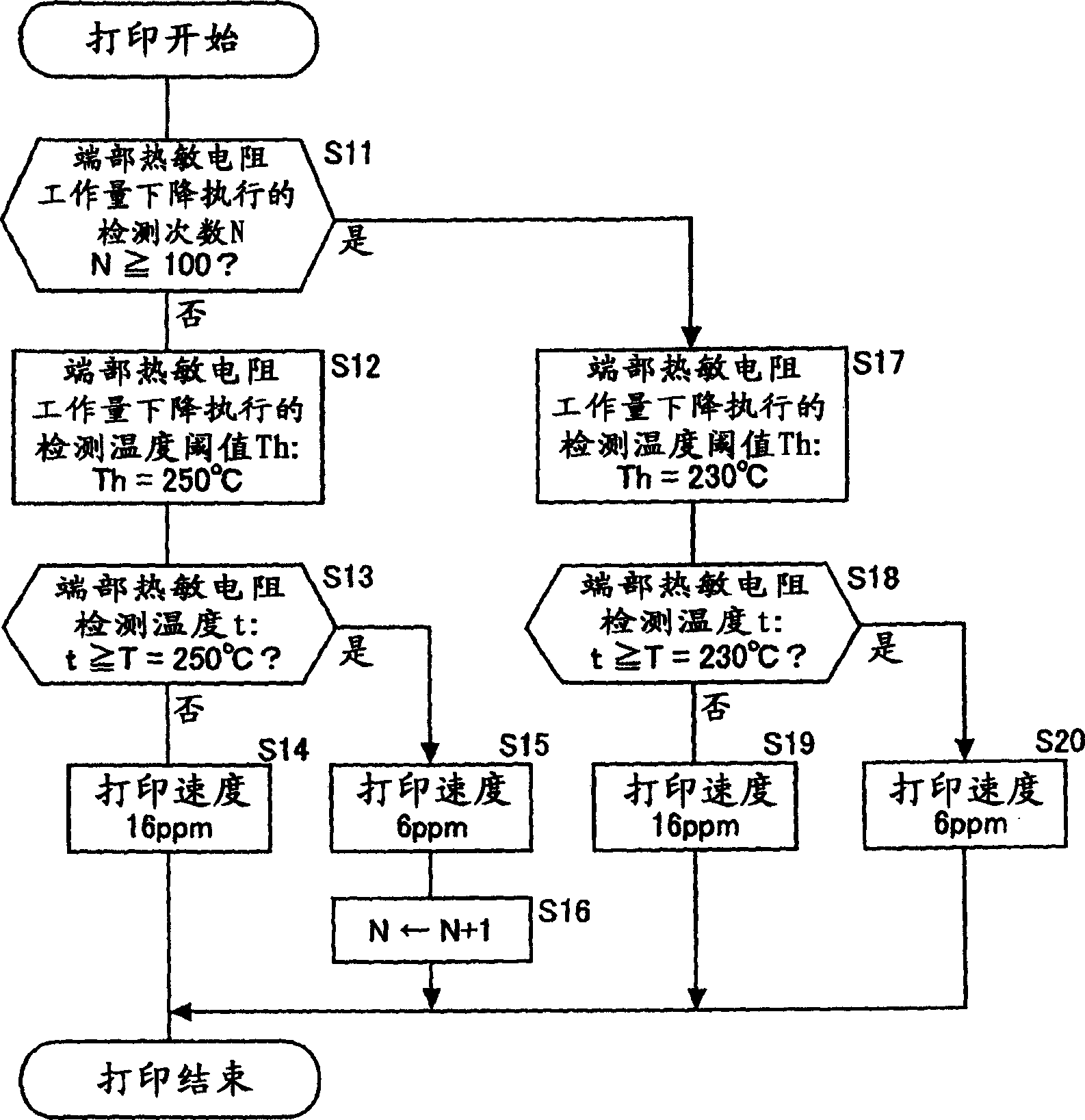

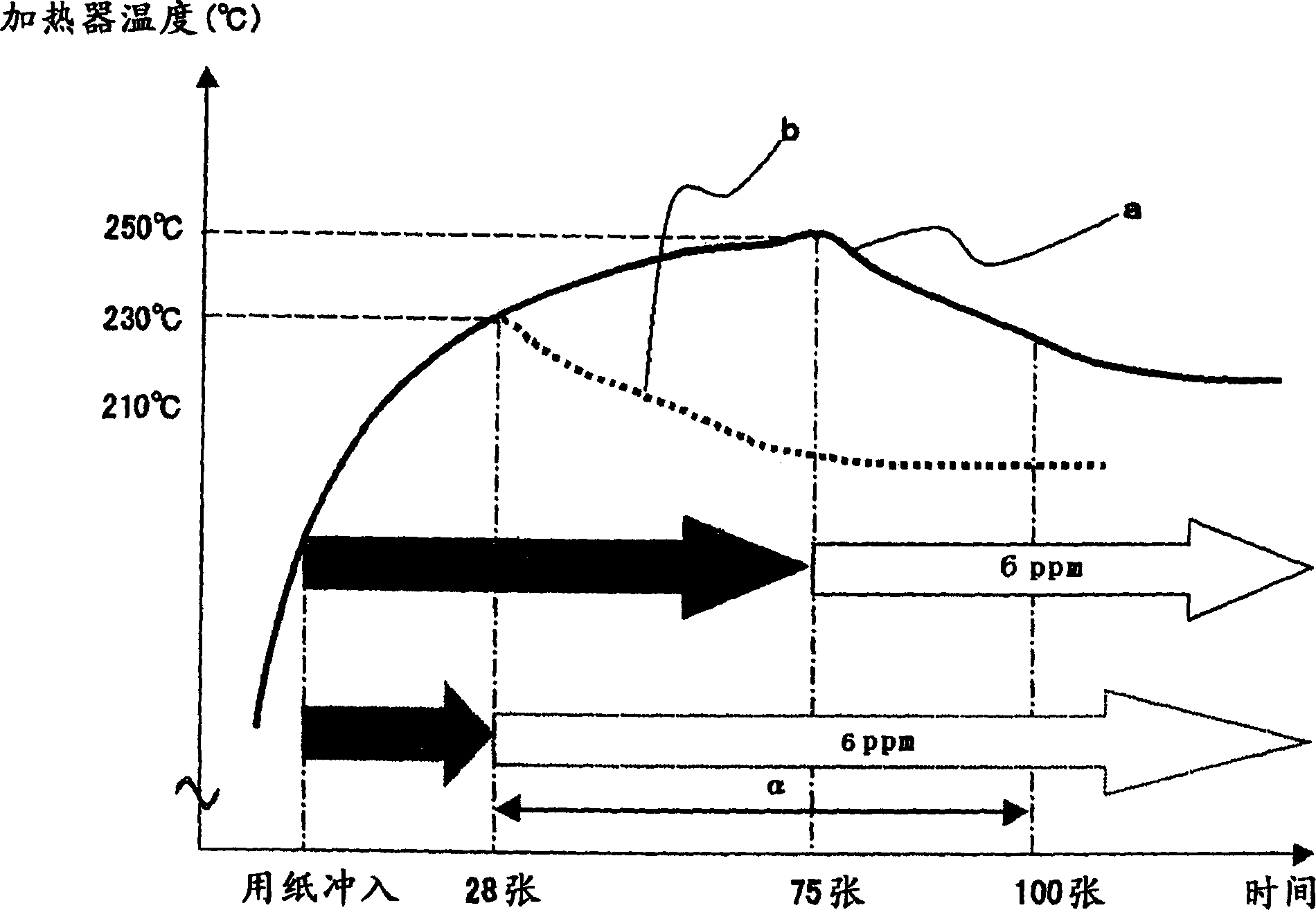

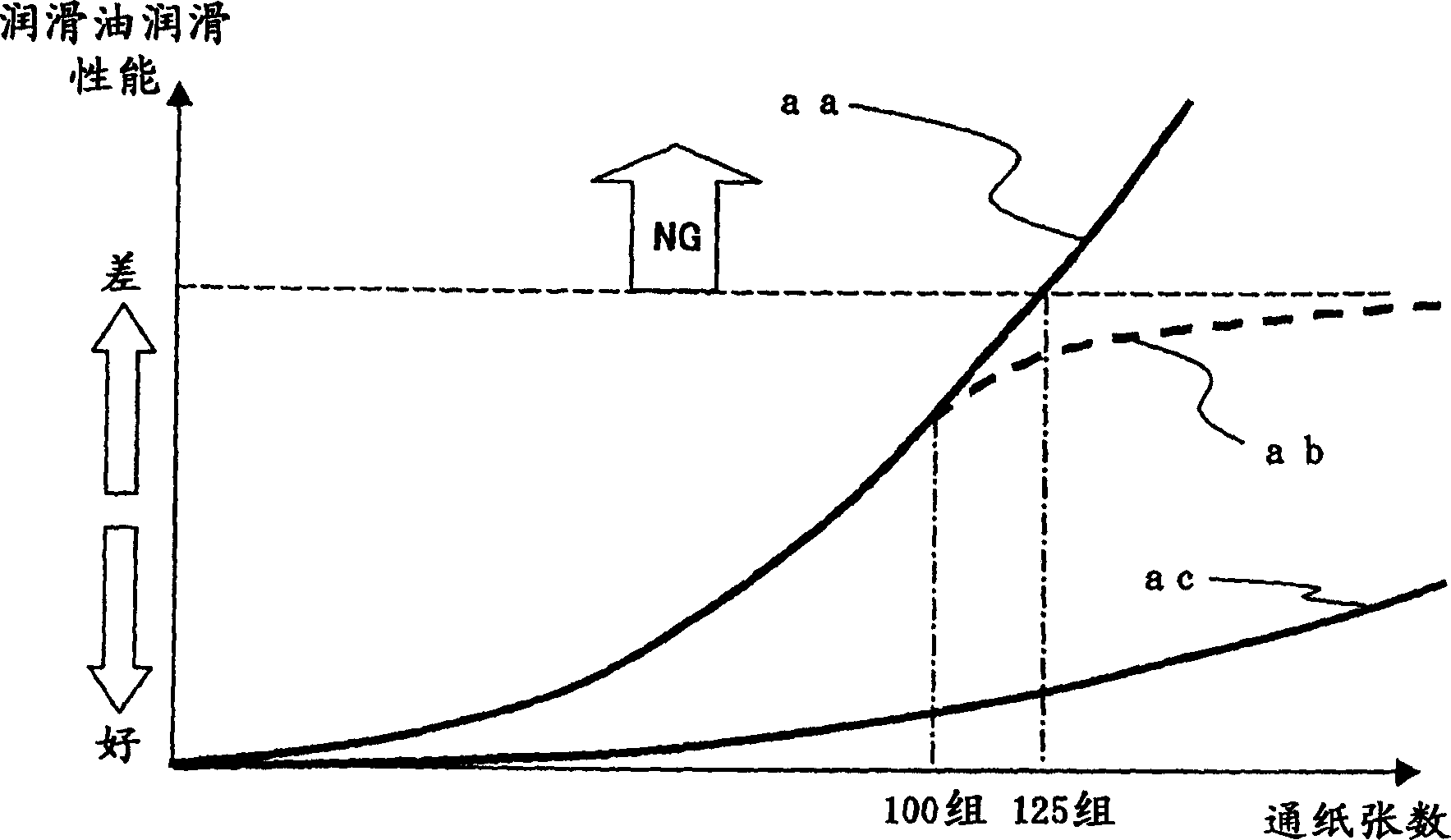

[0046] Since the outline of the fixing device is the same as that of the aforementioned first embodiment, description thereof will be omitted. Figure 7 The flow chart of is schematically showing the control procedure of the image forming apparatus in this embodiment. In addition, Table 2 shows the relationship between the paper passing ratio of the small-sized recording material and the threshold temperature Th at which the thermistor provided at the end lowers the throughput.

[0047] Small size through paper ratio Ax

End of the drop in throughput

Thermistor detection temperature threshold

Ax≥50%

230℃

Ax<50%

250℃

[0048] exist Figure 7 In the process of , when the image forming apparatus main body receives a print signal, it starts a print operation. A unit that detects the length of the recording material P in the width direction, such as a size detection sensor provided in a main body ribbon cassette not shown, dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com