Pattern forming method and pattern forming apparatus

A pattern and linear technology, applied in the field of forming patterns on the substrate, can solve the problems such as difficult to form lattice patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

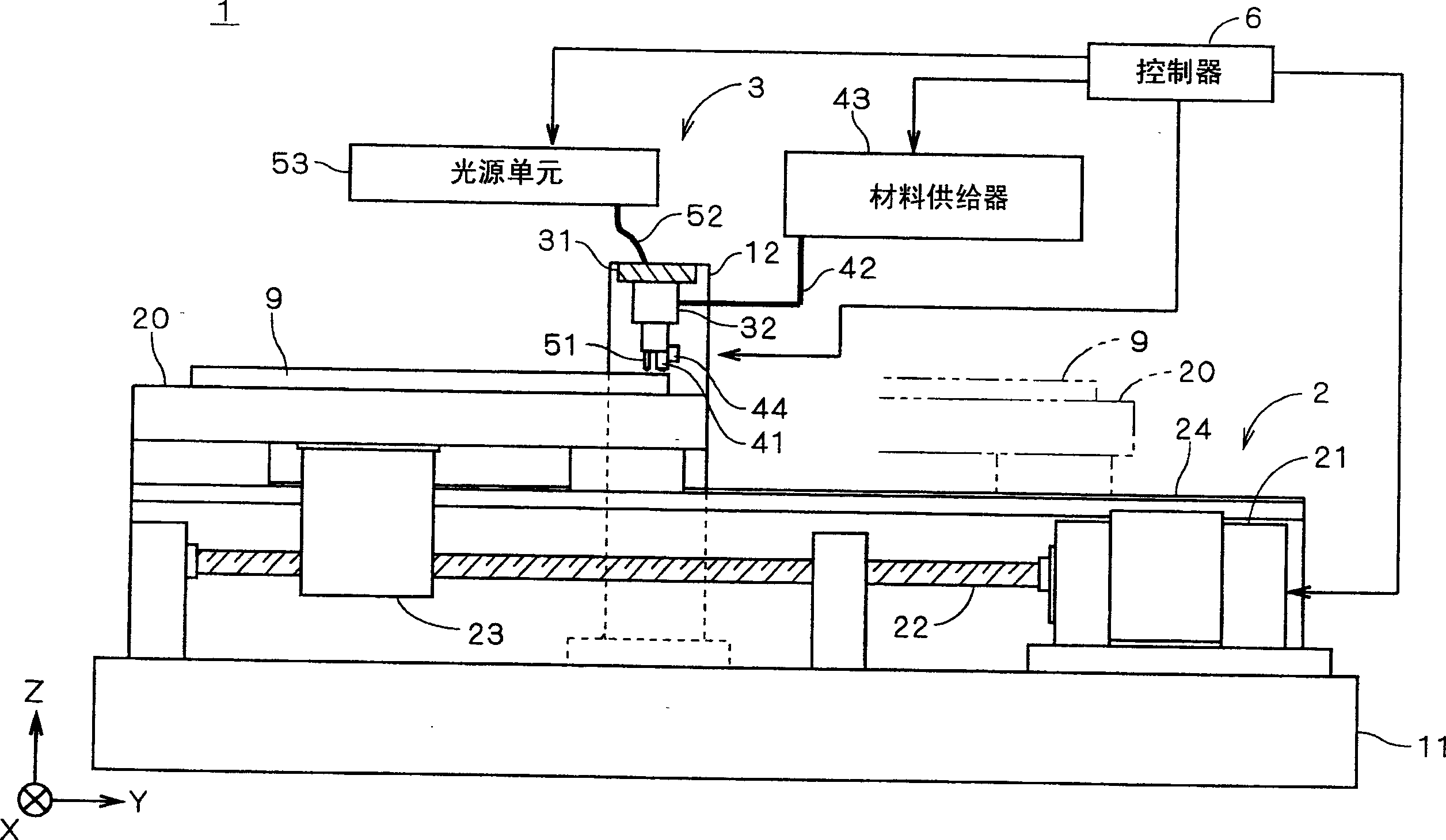

[0027] figure 1 is a configuration view of a patterning device according to a first preferred embodiment of the present invention. The pattern forming device 1 is a device for forming a pattern corresponding to a plurality of isolation ribs on a plasma display glass substrate (hereinafter referred to as "substrate") 9, and the substrate 9 on which the pattern is formed is formed by other methods. Becomes the panel (usually the rear panel) that is a component of a plasma display.

[0028] The pattern forming device 1 includes a stage moving mechanism 2 provided on a base 11 . Then, the workbench 20 for fixing the substrate 9 can be moved along the main surface of the substrate 9 (i.e. figure 1 shown in the Y direction) to move. In addition, the frame 12 is fixed on the base 11 to traverse the working platform 20 . Furthermore, the head 3 is connected to the frame 12 .

[0029] The table moving mechanism 2 includes a motor 21 connected with a ball screw 22 , and also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com