Spinning appuratus and method and hollow guide shaft member for spinning

A technology for guiding shafts and components, applied in spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problems of increased yarn breakage, decreased spinnability, and decreased yarn strength, etc. Achieve the effect of preventing yarn quality decline and yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

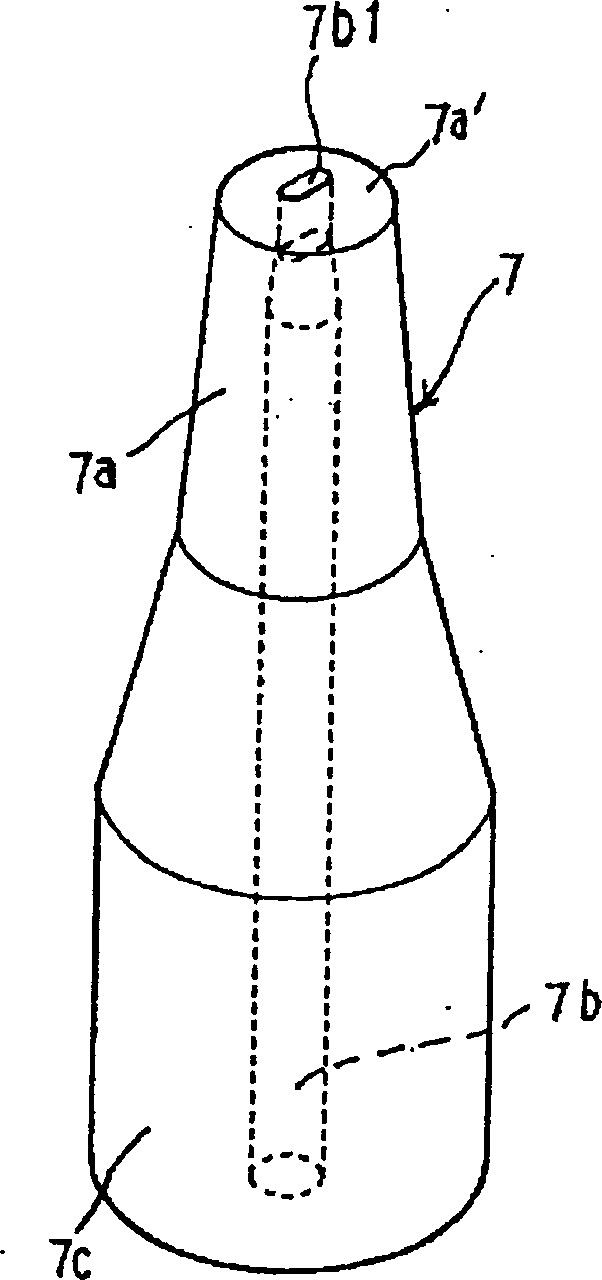

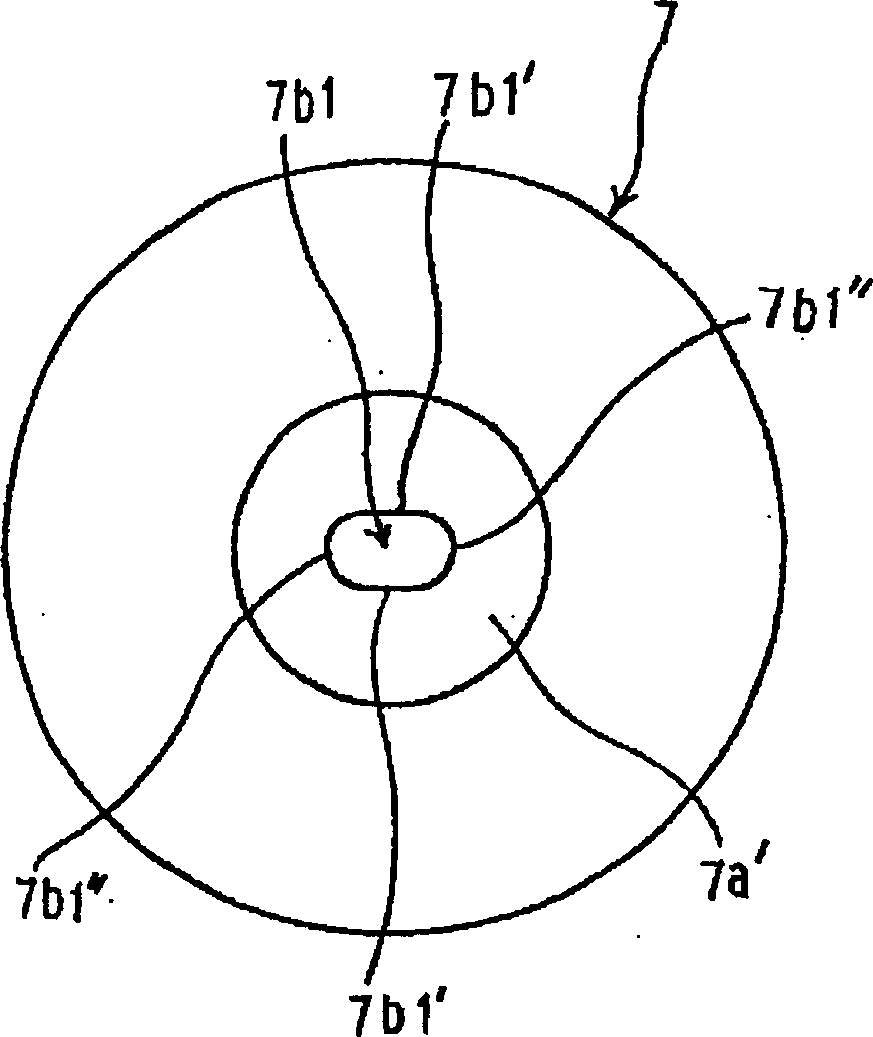

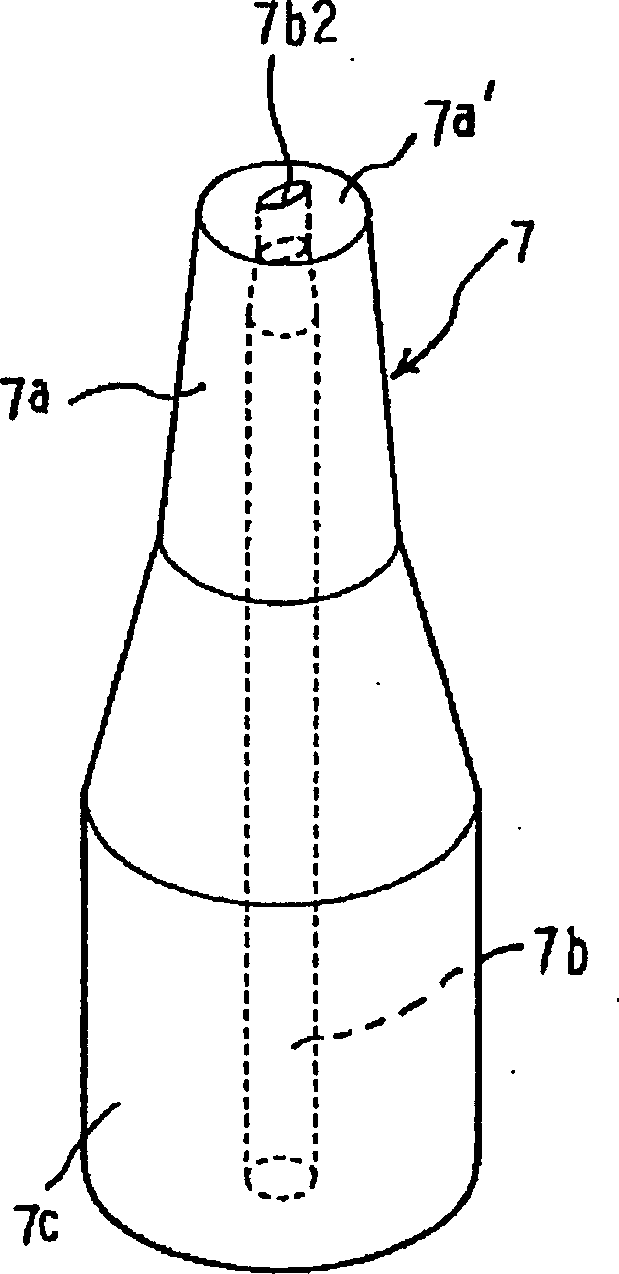

[0050] Use the following Figure 1 to Figure 15 Examples of the present invention will be described, but the present invention is not limited to the examples described below unless the gist of the present invention is deviated from.

[0051] First, the overall configuration of the spinning device will be described using FIG. 12 . In Fig. 12, V is the sliver supplied to the drafting device D through the yarn guide G. The second roller d3 and the front roller d4 form. In the drafting device D, the sliver V to be drafted is supplied to the spinning unit U described later, and after the yarn Y is formed by the spinning unit U, the yarn Y passes through the yarn composed of the nip roller h1 and the delivery roller h2. The yarn feeding device H, the loose tube T configured as a suction tube, the yarn clearer Z, etc., are wound on the winder w3 supported on the cradle w2 driven by the friction roller w1 of the winding section W. In addition, as described above, the spinning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com