Mask assembly and mask frame assemble using same

A technology of mask assembly and mask frame, which is applied in the directions of electrical components, electrical solid-state devices, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

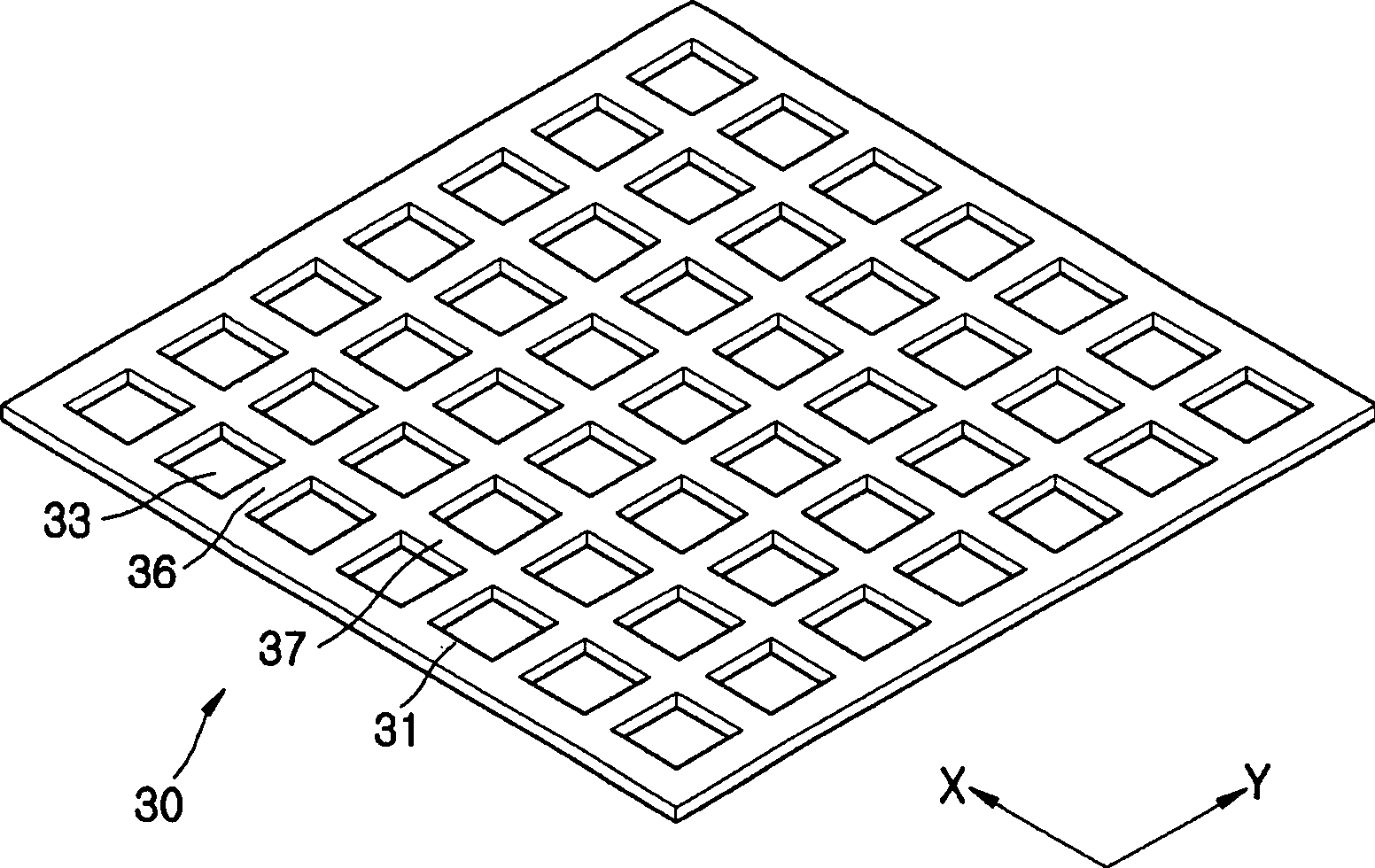

[0026] image 3 is one embodiment of an open mask used in some embodiments of the invention as part of a mask assembly for depositing thin films of organic electroluminescent (EL) devices.

[0027] refer to image 3 One embodiment of the opening mask 30 includes a plurality of openings 33 corresponding to a plurality of unit devices to be formed on a motherboard (not shown). Here, the motherboard refers to a substrate on which an organic EL device can be formed using a mask assembly. In some embodiments, after molding using a mask, each unit device is cut from the motherboard by scribing to form one organic EL device.

[0028] In some embodiments of the present invention, the opening mask 30 includes a plurality of ribs 36 that are parallel with respect to each other, arranged with an equal gap between each rib 36 . Ribs 36 in the column direction (according to image 3 Extending in the y-direction of the coordinate system of ), the plurality of ribs 37 are parallel to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com