Filter assembly utilizing carbon block and pleated filter element

A filter assembly, filter element technology, applied in the direction of cartridge filter, filtration separation, filtration treatment, etc., can solve problems such as disclosure or proposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

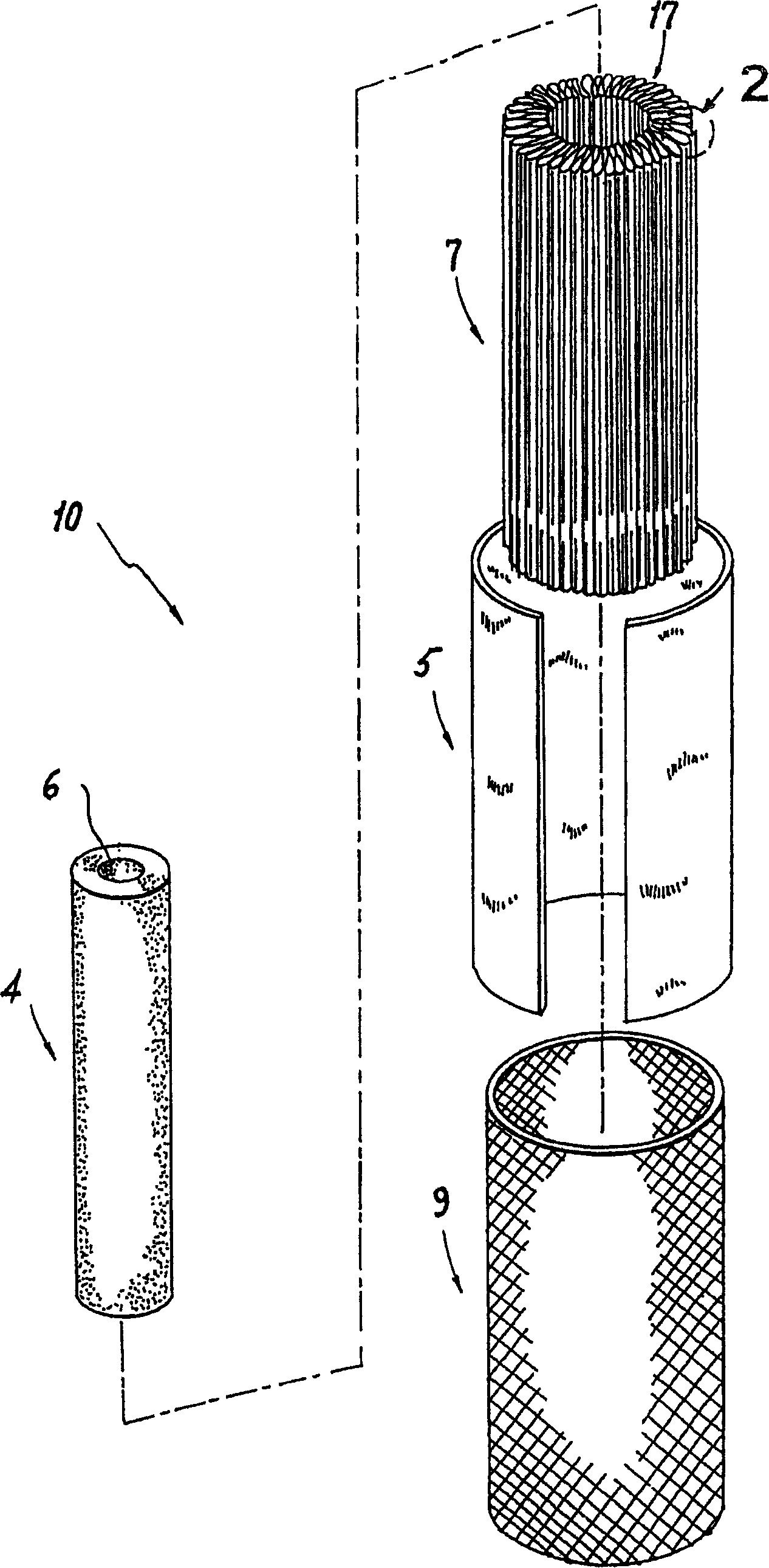

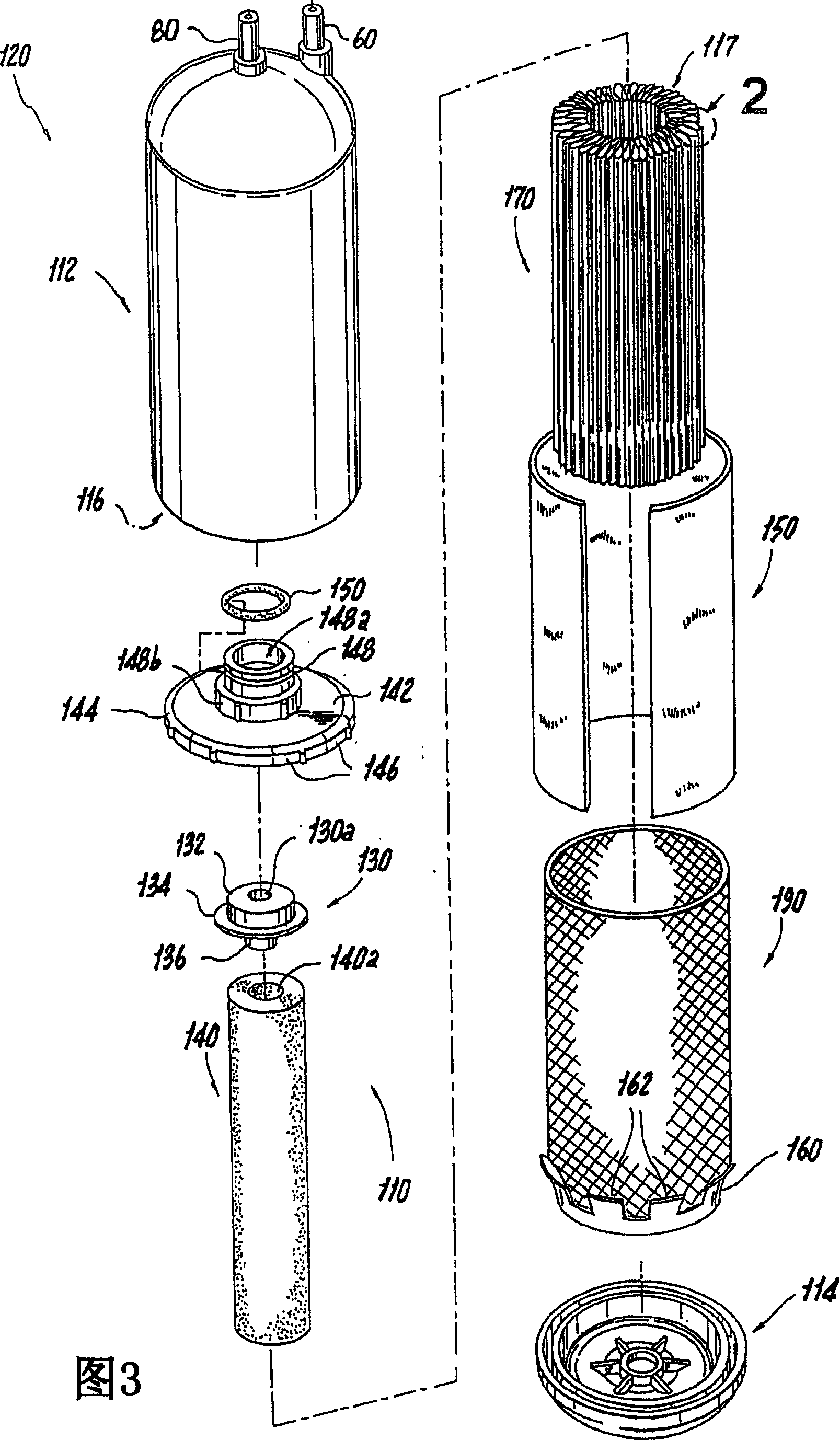

[0028] Referring to the accompanying drawings, wherein like reference numerals denote like structural elements of the filtration device described herein, figure 1 An exemplary filter assembly constructed in accordance with the present invention is shown generally at 10 . Such as figure 1 As shown, the filter assembly 10 includes a generally cylindrical carbon block filter element 4 having an axial cavity 6 extending through the filter element 4 or not. Such carbon block filter elements can be produced according to, for example, US Patent Nos. 5,928,588 and 5,882,517 to Wei-Chih Chen et al. Both of these patents have been assigned to Cuno Corporation, the contents of which are incorporated herein by reference.

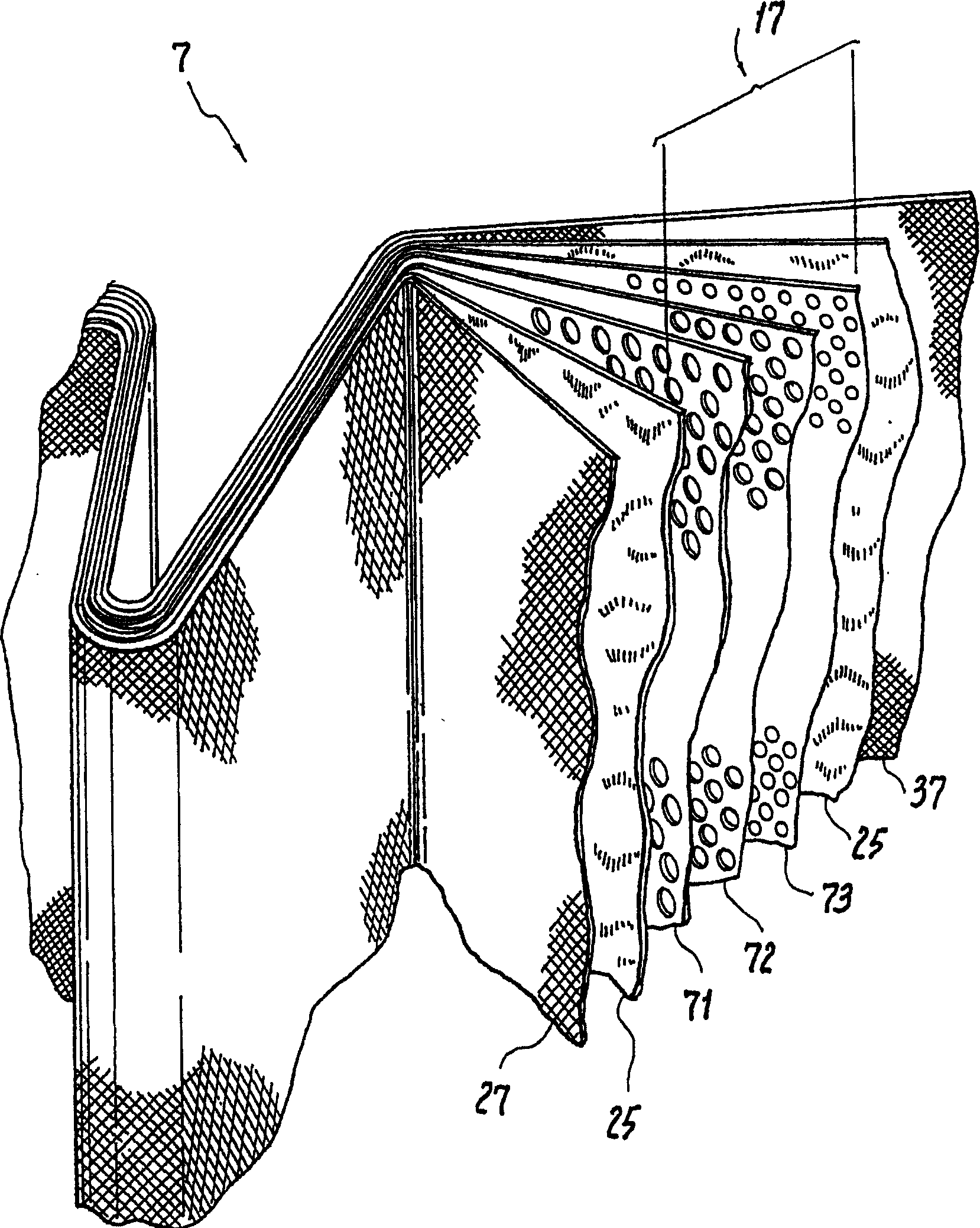

[0029] Such as figure 1 As shown, the filter assembly 10 also includes a generally cylindrical pleated filter element 7 disposed around the outer circumference of the carbon block filter element 4 . An exemplary pleated filter element 7 suitable for use in embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com