Driving mechanism of rapier belt for rapier loom

A driving mechanism and rapier loom technology, applied in the field of textile machinery and rapier looms, can solve the problems of high manufacturing cost, high manufacturing precision and material requirements, and many transmission links of the weft insertion device, and achieve a simple and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

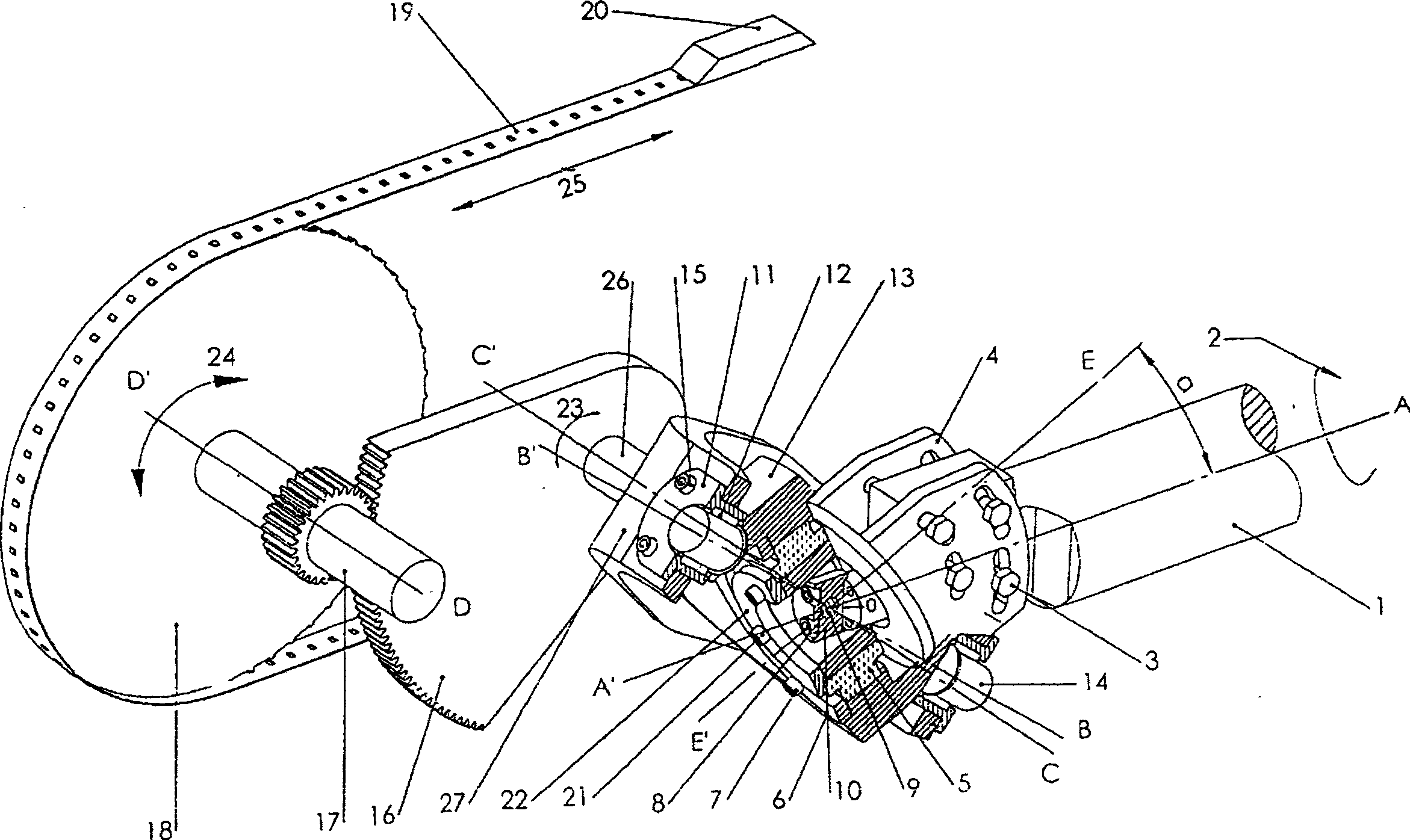

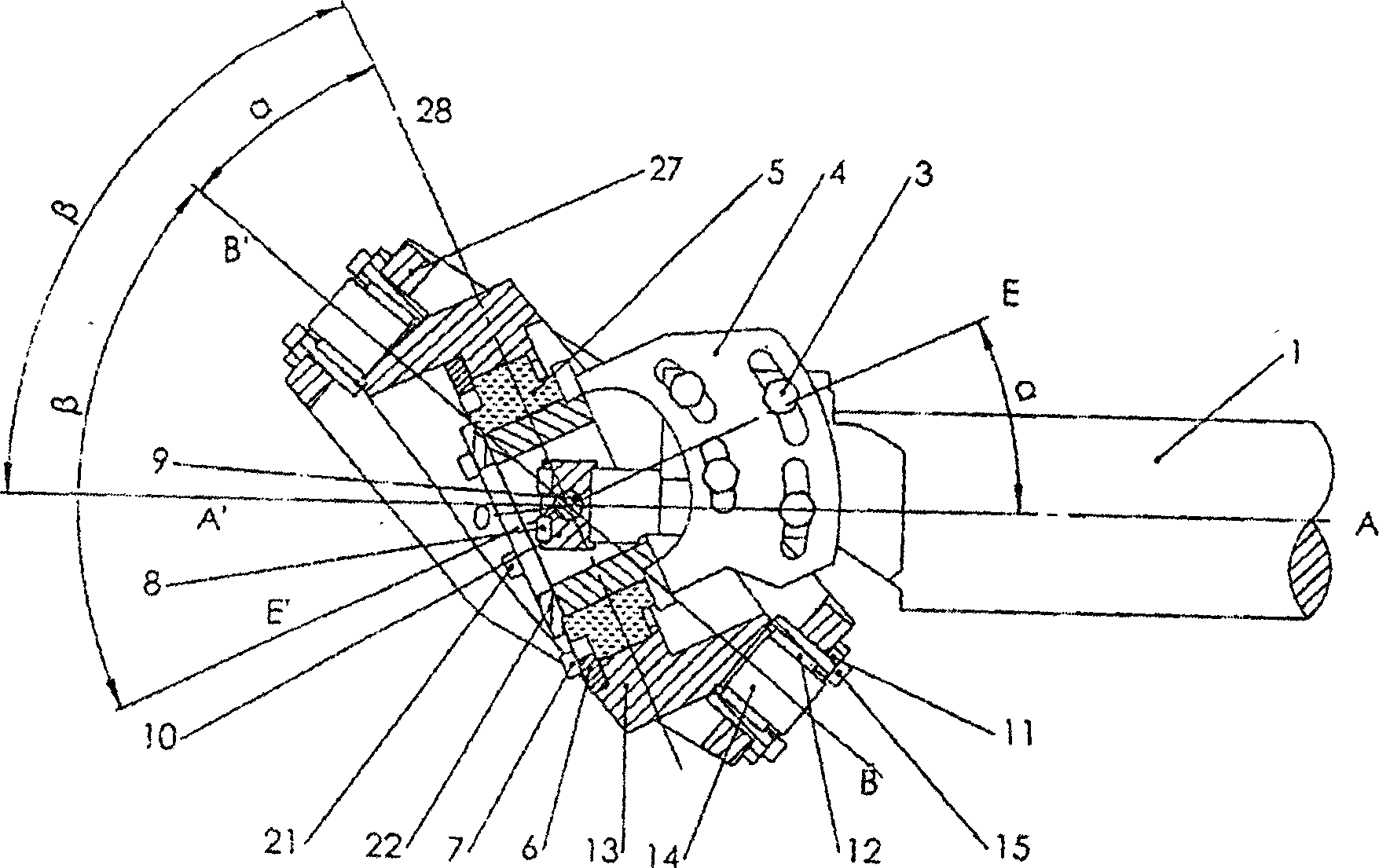

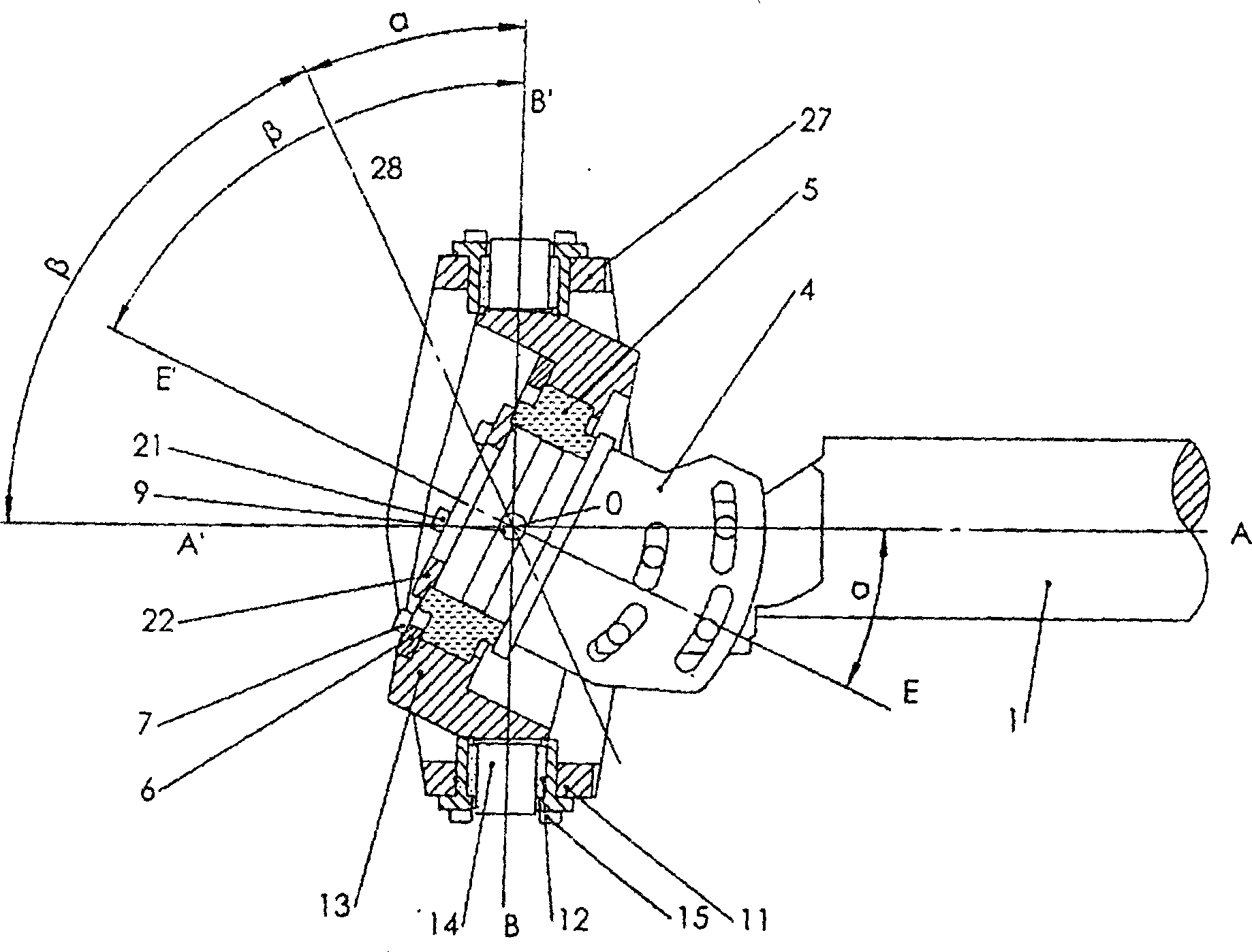

[0016] Such as figure 1 , figure 2 and image 3 As shown, the rapier driving mechanism for rapier looms of the present invention is composed of a main shaft 1, a motion conversion mechanism and a sword transmission wheel 18, the main shaft 1 is connected with the motion conversion mechanism, and the movement The conversion mechanism is connected with the sword wheel 18, wherein the motion conversion mechanism is composed of the tilting head 4, the central flange 10, the oblique ring 13, the swing ring 27 and the swing gear 16, and the central flange 10 The screw 8 is fixedly connected to the head of one end of the main shaft 1, and the two sides of the tilted head 4 are fixedly connected to one end of the main shaft 1 by bolts 3. The front side of the tilted head 4 is set There is a shaft, the shaft end on the front side of the tilting head 4 is fixedly connected to the central flange 10 through a pin 9, the rotation axis EE' of the tilting head 4 and the central axis AA' o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com