Manufacturing method of multicore multi colour transparent dressing brush handle

A manufacturing method and technology of cosmetic brushes, applied in the direction of manufacturing tools, household components, household appliances, etc., can solve the problems of insufficient diversification and high-grade, and the inability to manufacture diversification and high-grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

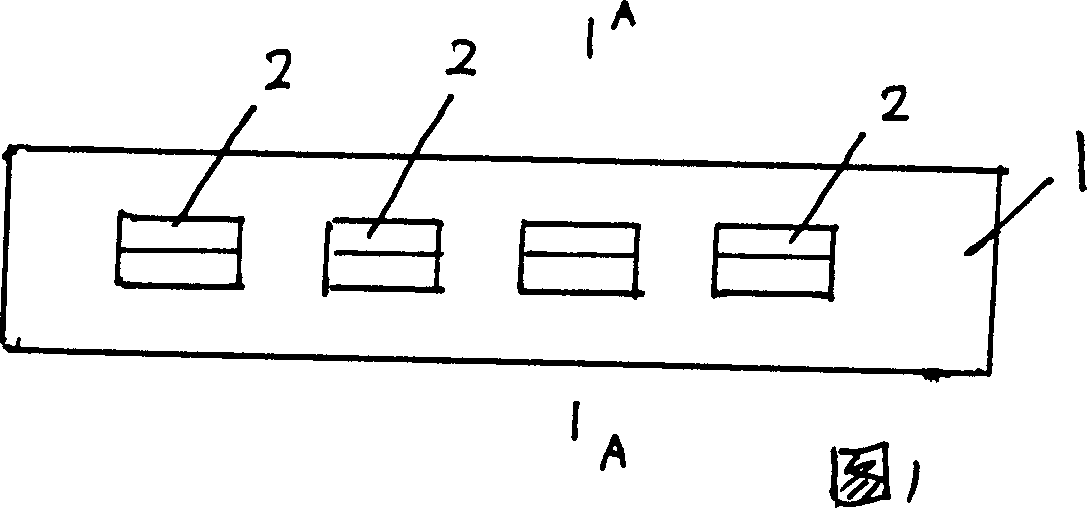

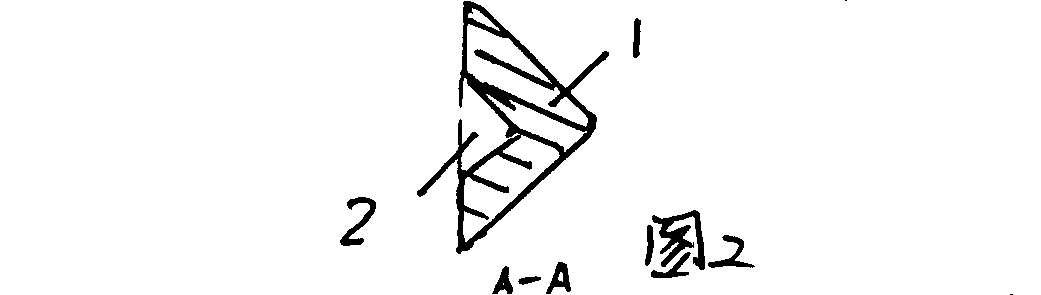

[0017] As shown in Figure 1 and 2:

[0018] A method for manufacturing a multi-core, multi-color transparent cosmetic brush handle. First, two independent half transparent brush handles 1 with the axis of the brush handle as the interface are manufactured by injection molding, and the two independent half transparent brush handles are simultaneously Make a plurality of corresponding grooves 2 on the surface of the axial section of the transparent brush handle, inject colored resin in a plurality of corresponding grooves, and make the surface of the injected colored resin and the surface of the transparent brush handle with the axial section become a plane.

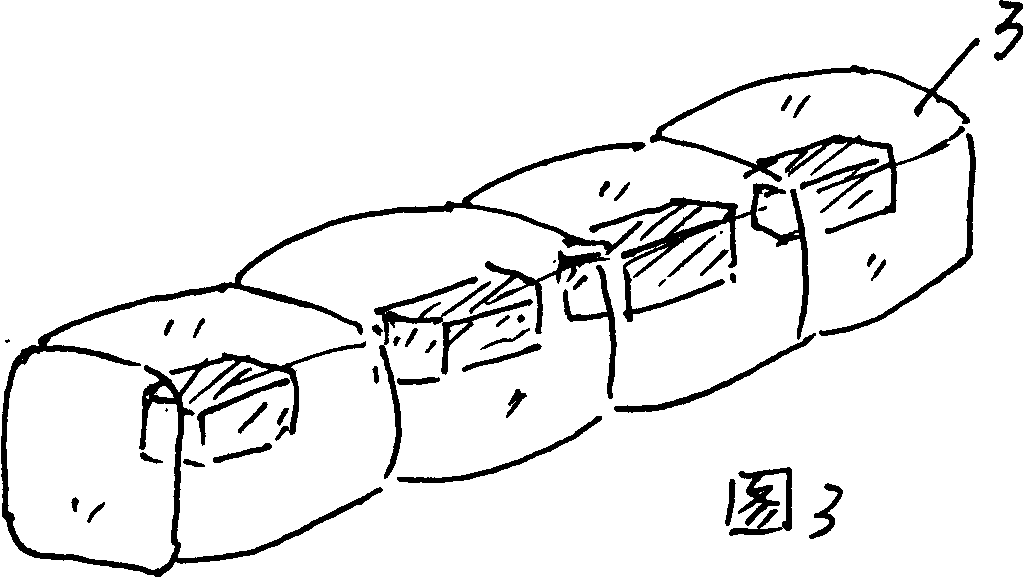

[0019] Then, the surfaces of the two corresponding half transparent brush handles filled with colored resin are correspondingly bonded to form an integral multi-core multi-color transparent cosmetic brush handle 3 . As shown in Figure 3.

[0020] According to the manufacturing method of the multi-core multi-color transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com