Device for drawing internal and outernal ring of bearing

A puller, inner and outer ring technology, applied in the field of machinery, can solve the problems that the disassembly device cannot be used normally, the bearing outer ring cannot be disassembled, and the working reliability is low, and achieves the effects of simple structure, low cost, and high use reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

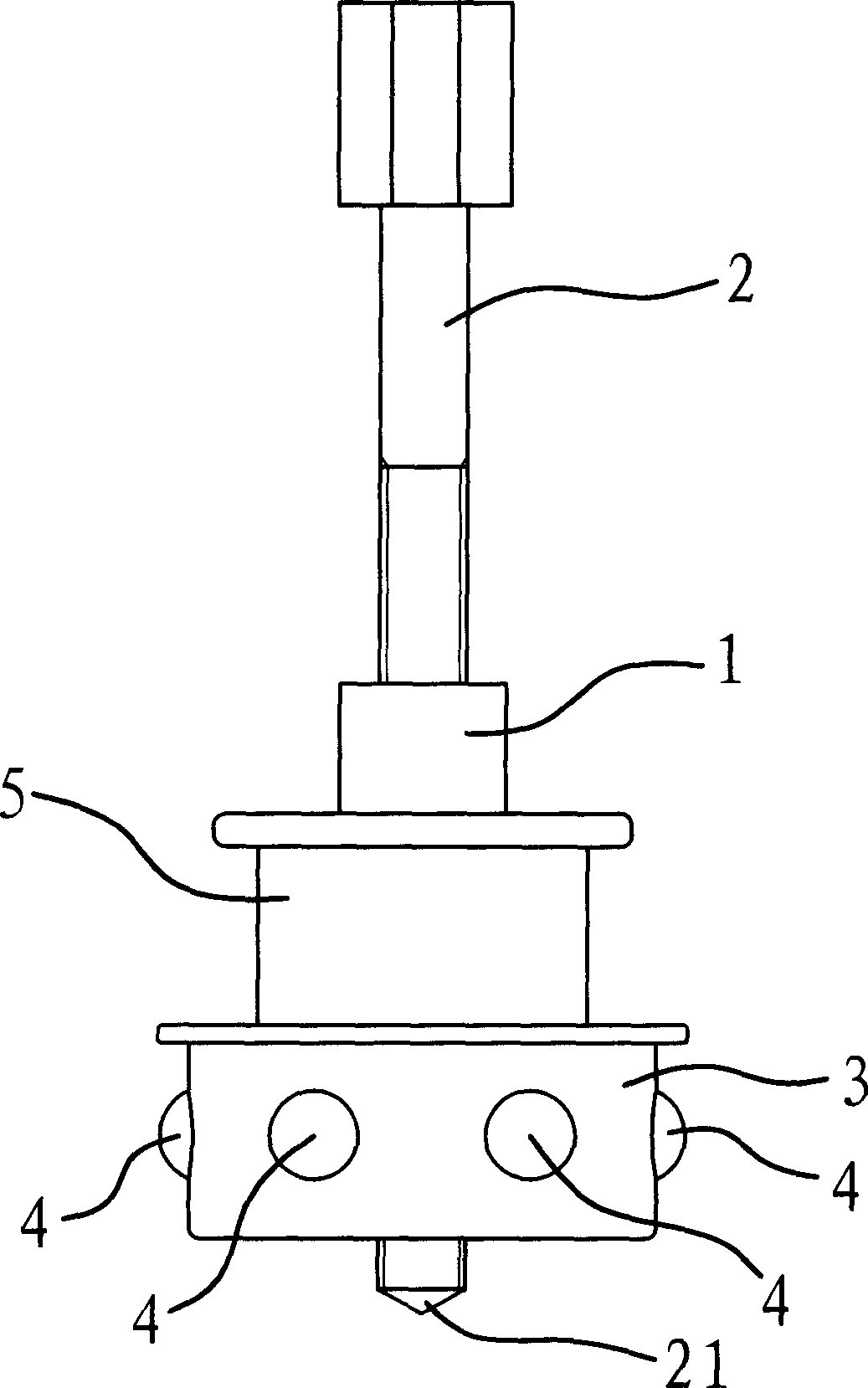

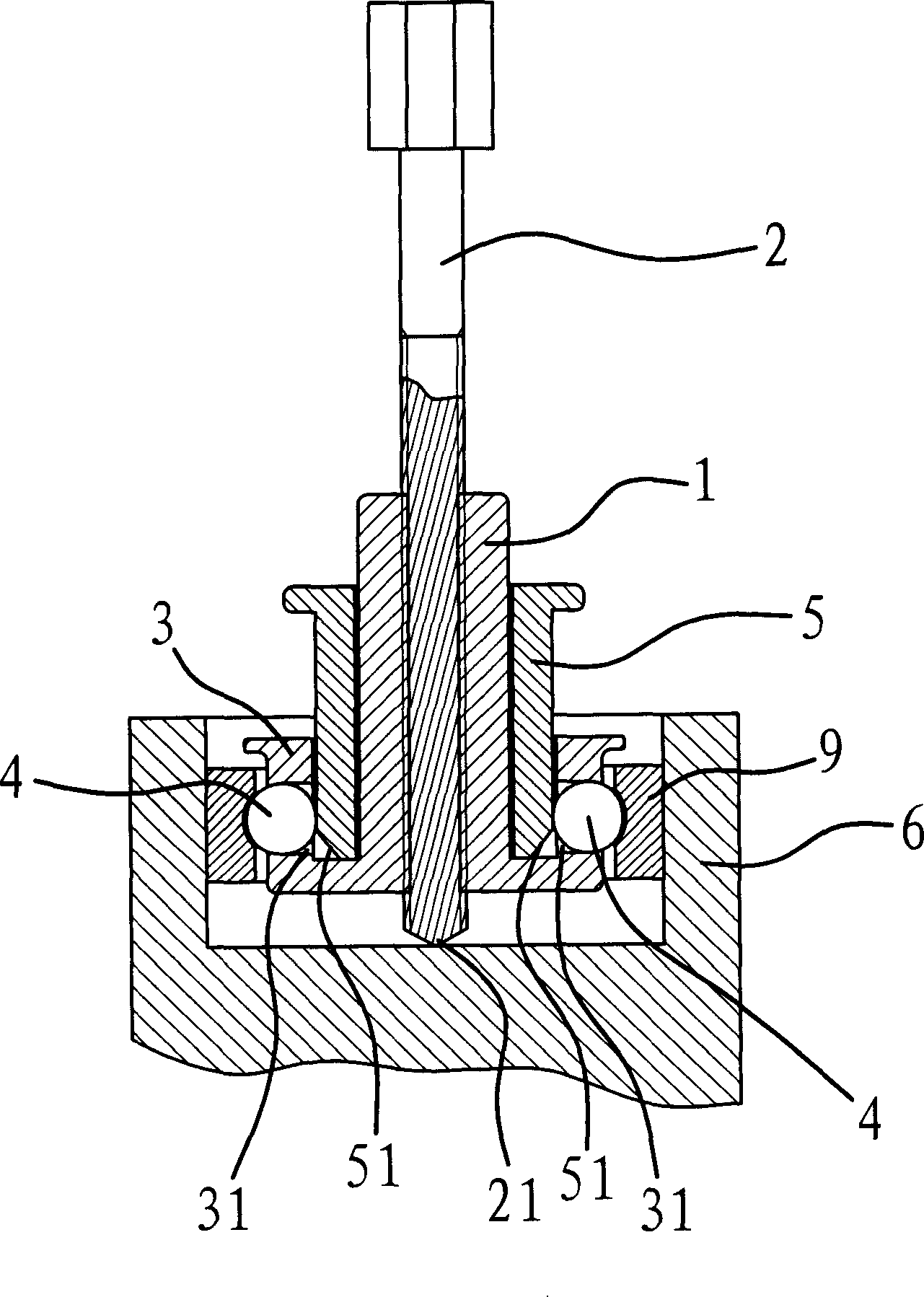

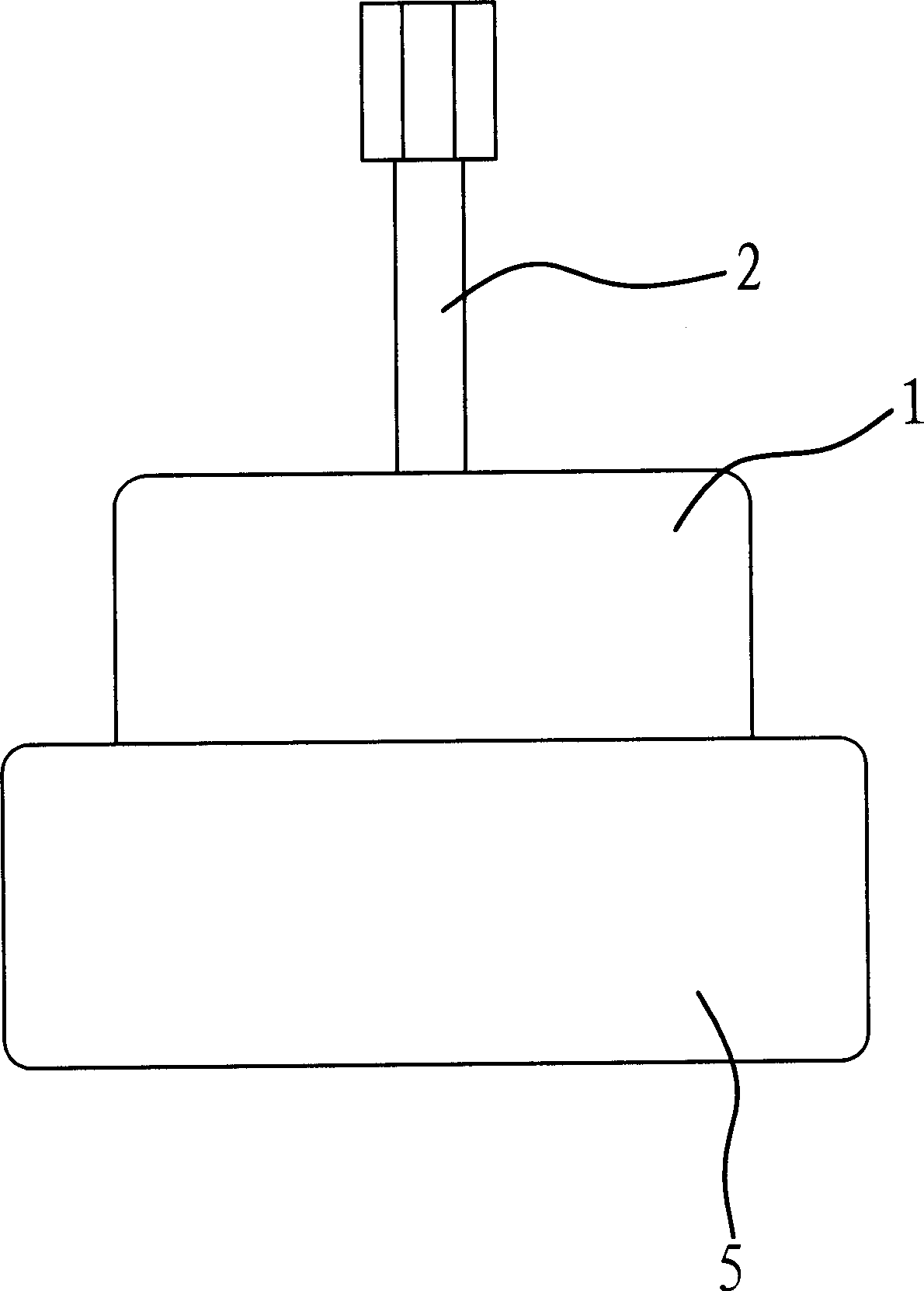

[0029] Such as figure 1 and figure 2 As shown, the bearing inner and outer ring puller is used to remove the bearing outer ring 9 installed in the bearing seat 6, and it includes a cylindrical main body 1, screw rod 2, slider seat 3, slider 4 and bushing 5 .

[0030] The middle part of the main body 1 is provided with a through threaded hole, and the screw rod 2 is connected in the threaded hole. The inner end of the screw rod 2 is a sharp angle 21, and the outer end is a regular hexagon. The operator can hold the regular hexagon at the outer end of the screw 2 to rotate the screw 2 .

[0031] The end of the main body 1 is fixedly connected with a slider seat 3, which is cylindrical. In this embodiment, for the convenience of processing, the main body 1 and the slider seat 3 adopt an integrated structure. The outer surface of the slider seat 3 is evenly provided with six through holes 31 , and each through hole 31 is equipped with a slider 4 . In this embodiment, the sli...

Embodiment 2

[0036]The principle and structure of this embodiment are basically the same as those of Embodiment 1, except that the diameter of the through hole 31 at the inner and outer surfaces of the slider seat 3 is slightly smaller than the outer diameter of the ball. The bushing 5 is directly sleeved on the outside of the slider seat 3 . In this embodiment, in order to prevent the bushing 5 from falling off, a stop edge 32 for blocking the bushing 5 is provided at the bottom of the slider seat 6 .

[0037] When in use, the slider seat 3 is sleeved on the bearing inner ring 8 . When the through hole 31 corresponds to the annular groove on the inner ring 8 of the bearing, put down the bushing 5 . The bushing 5 squeezes the slider 4 so that the slider 4 partially protrudes from the inner side of the through hole 31 , and the partially protruded slider 4 is stuck in the annular groove of the bearing inner ring 8 . At this time, turn the screw 2. When the sharp corner of the inner end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com