High-precision hobbing tool for gears and application method thereof

A high-precision, gear technology, which is applied in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of many steps of clamping and dismounting gears, time-consuming and labor-intensive problems, and achieve low skill requirements, Simple operation, time-saving and labor-saving disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

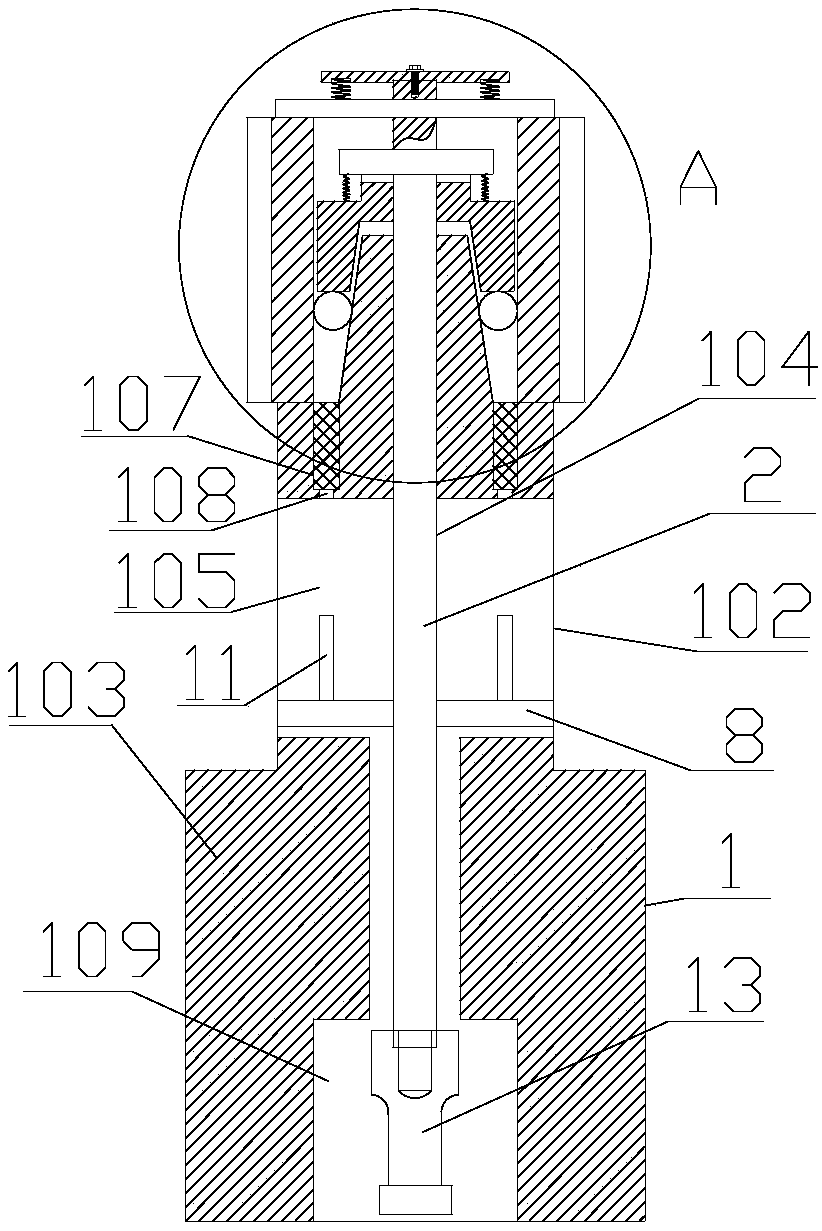

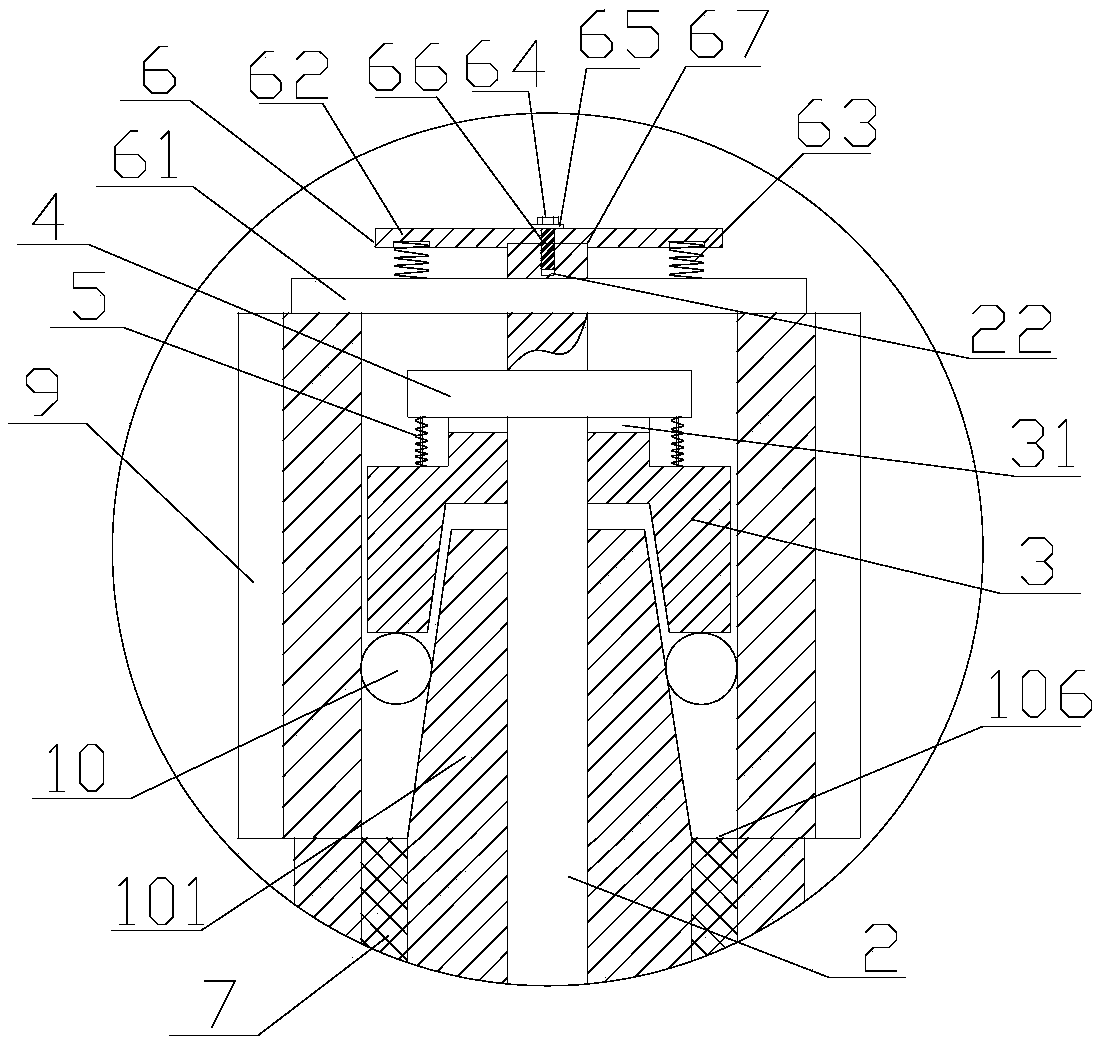

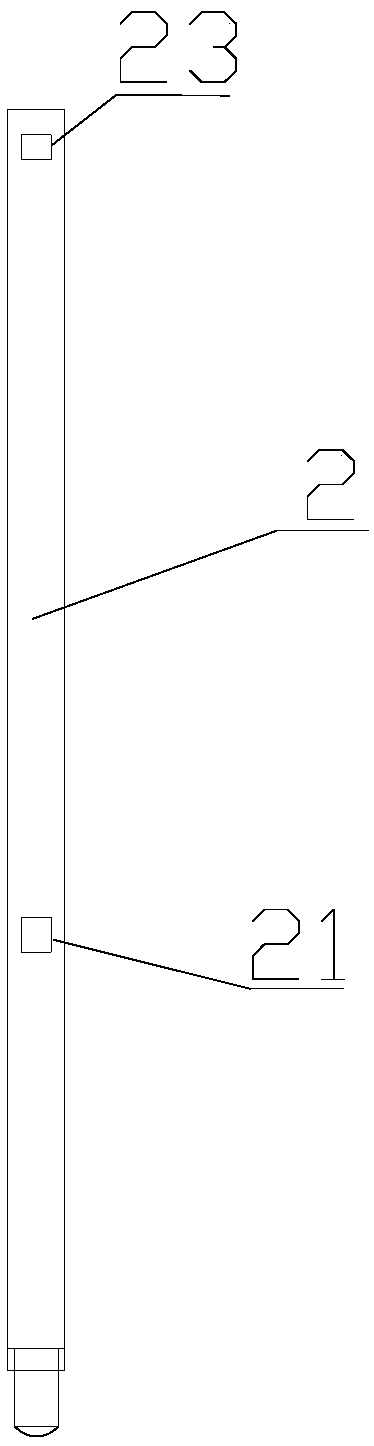

[0013] Embodiment 1: with reference to attached Figure 1-Figure 5 . A high-precision hobbing tool for gears, including a cone seat 1, the cone seat 1 is composed of a conical shaft section 101, a first circular shaft section 102 and a second circular shaft section 103 arranged in sequence from top to bottom and The centerlines of the tapered shaft section 101, the first circular shaft section 102, and the second circular shaft section 103 coincide, and the tapered shaft section 101, the first circular shaft section 102, and the second circular shaft section 103 are in the form of Overall structure and the diameter of the first circular shaft section 102 is greater than the diameter of the largest circle of the tapered shaft section 101 and the diameter of the first circular shaft section 102 is smaller than the diameter of the second circular shaft section 103, the cone The upper end surface of the seat 1 is provided with a through hole 104 passing through the upper and lowe...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, a method of using a high-precision gear hobbing tool, step 1, before the gear 9 is hobbed, firstly pass the first pressure plate 61 of the elastic pressure plate 6 through the pressure plate Pull it out from the hole 23, then place the gear 9 on the first shoulder 106 of the cone seat 1, then start the hydraulic lifting mechanism, and the hydraulic lifting mechanism drives the threaded connecting rod 13 to go up until the top sleeve 3 leaves the inner hole of the gear 9 and the gear 9 is on the The gap between the end surface and the lower end surface of the top sleeve 3 can pass through the steel ball 10; step 2, put the steel ball 10 into the gap between the upper end surface of the gear 9 and the lower end surface of the top sleeve 3 and insert the first pressure plate 61 back into the pressure plate through In the hole 23, start the hydraulic lifting mechanism afterwards, and the hydraulic lifting mechanism drives the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com