Cast-in-place continuous box girder formwork system and construction method

A box girder, cast-in-place technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of time-consuming and labor-intensive material loss, cumbersome disassembly and assembly procedures, and effective control of construction costs affecting the construction progress of box girder. , to achieve the effect of eliminating hidden dangers, saving time and effort in dismantling, and facilitating vibrating concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

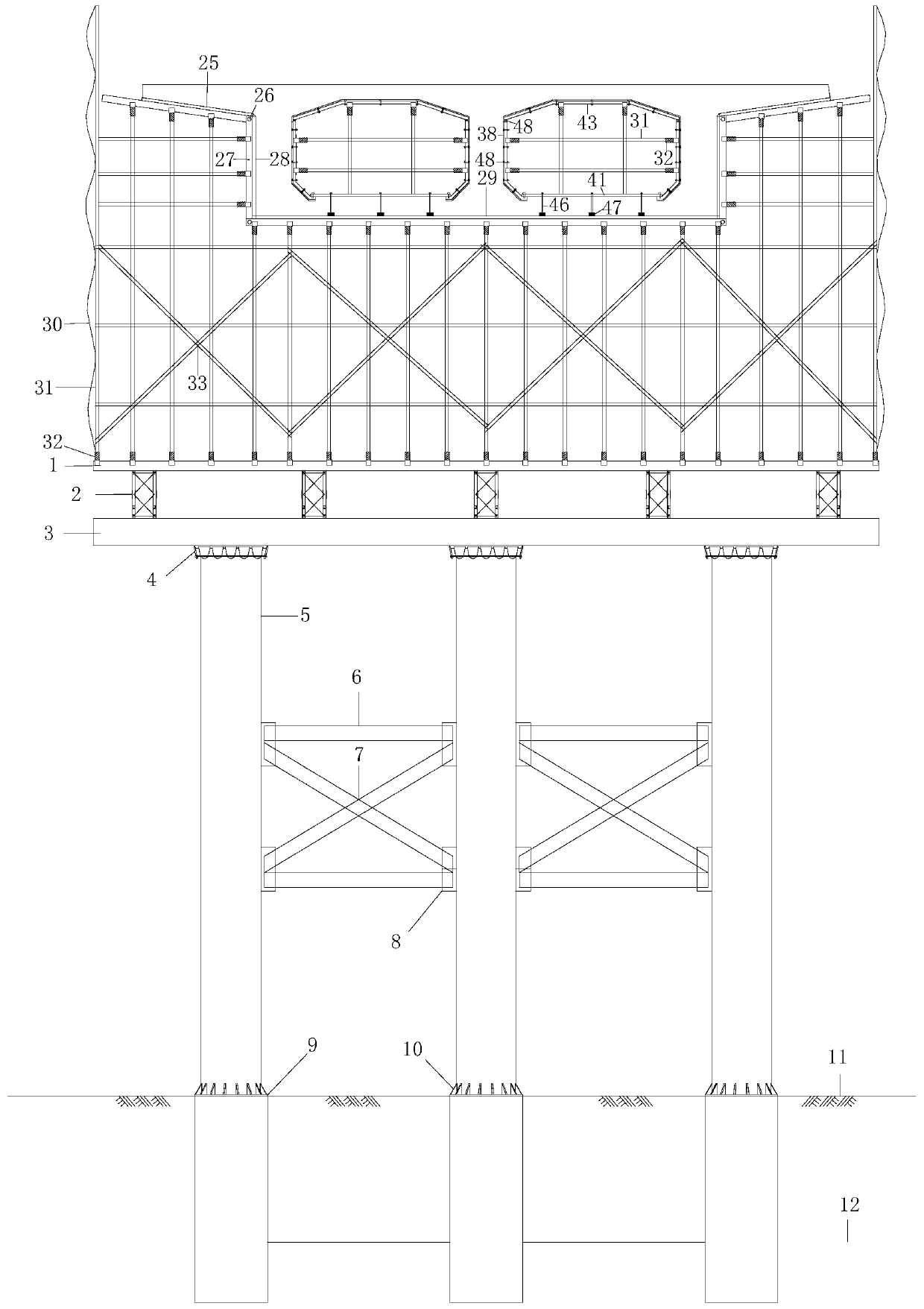

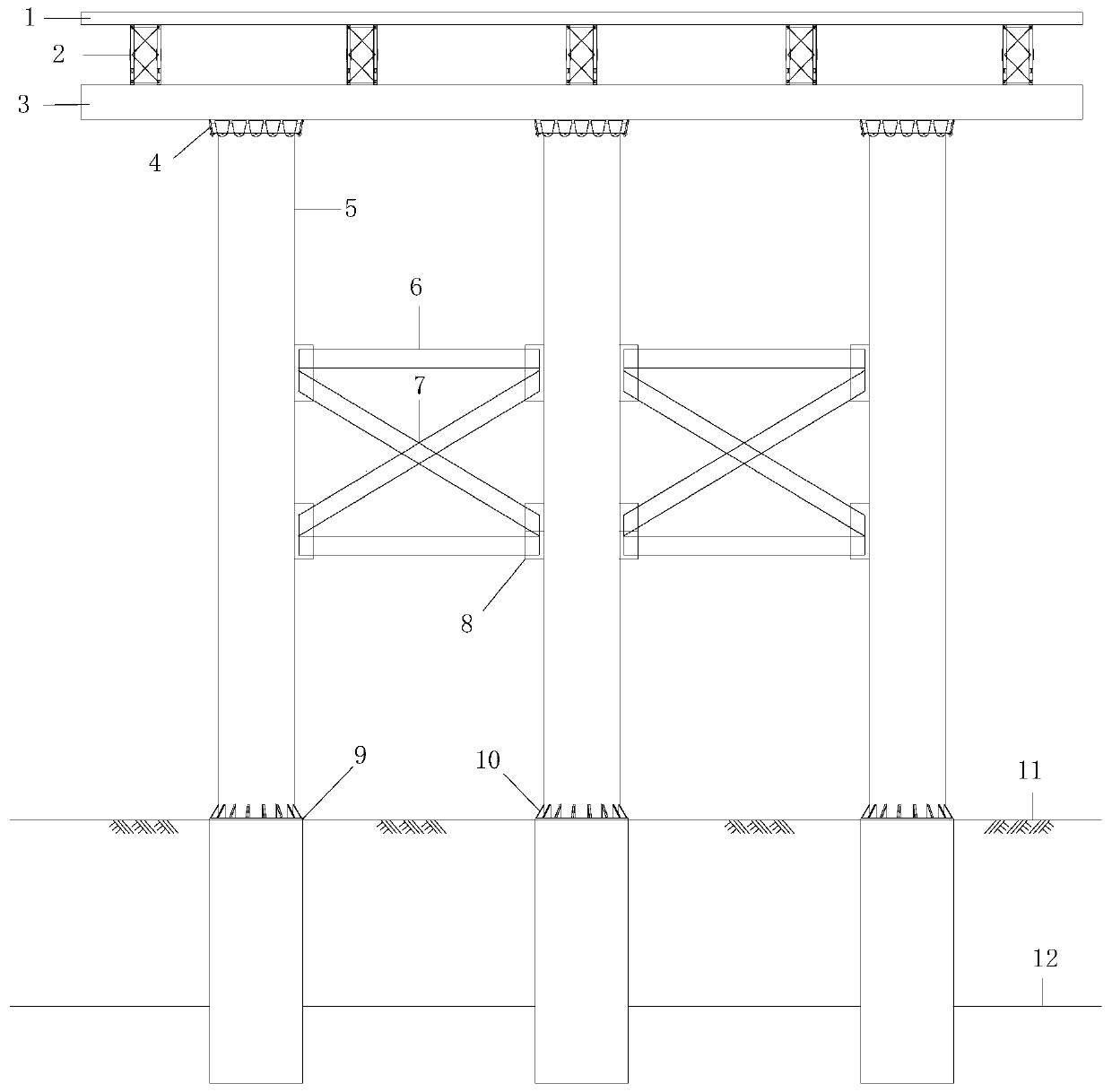

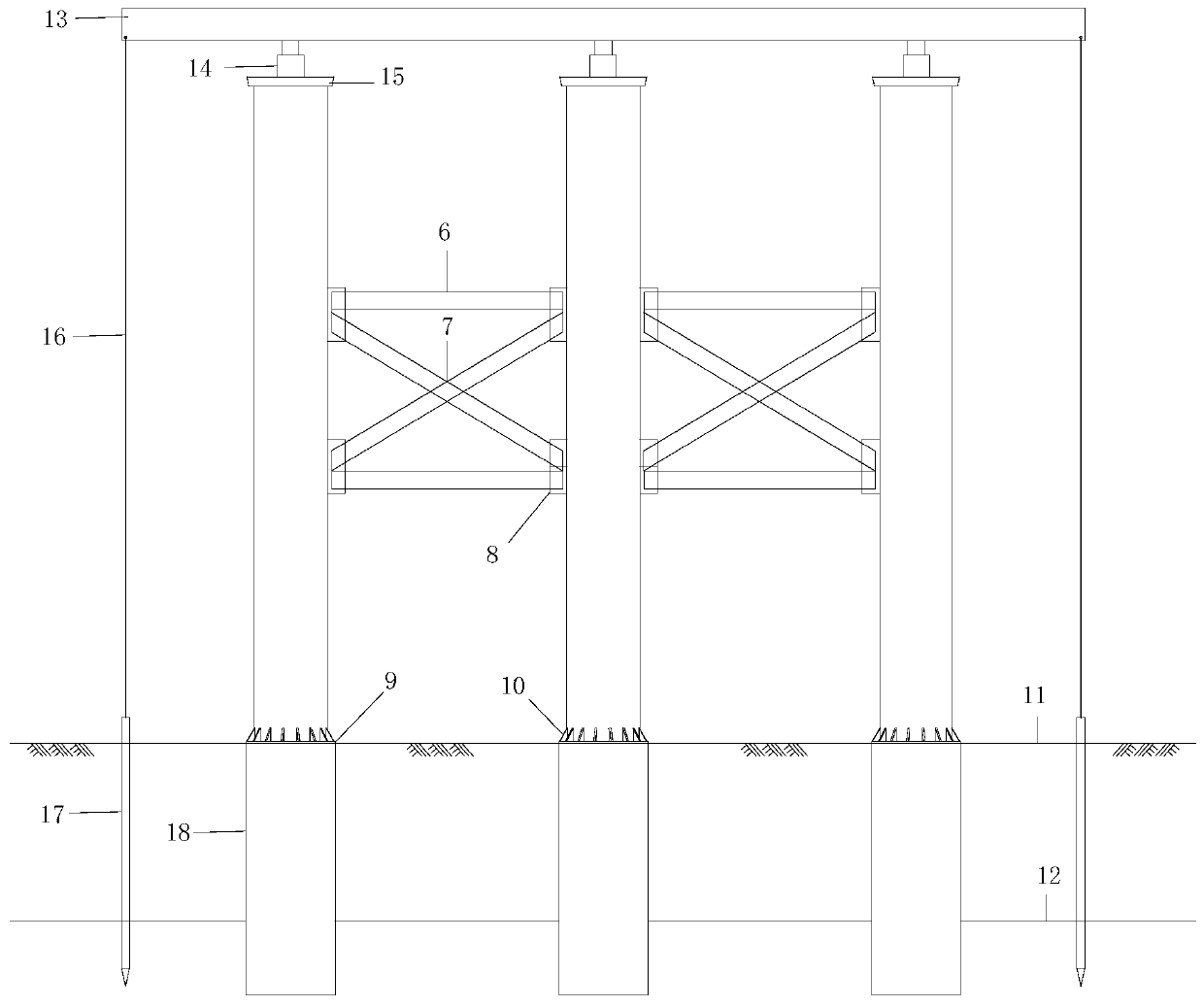

[0042] The cast-in-place continuous box girder formwork system includes a pile-supported cast-in-place continuous box girder support system, a cast-in-place continuous box girder outer formwork and a cast-in-place continuous box girder inner formwork.

[0043] The pile-supported cast-in-place continuous box girder support system includes a distribution beam 1, a Bailey beam 2, a load-bearing beam 3, a buckle device 4, a steel column 5, a horizontal strut 6, a scis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com