Lifting appliance for binding vertical reinforcement

A technology of vertical steel bars and hangers, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of poor binding firmness, low construction efficiency, poor positioning accuracy of steel bar binding, etc., and achieve reasonable structural design and construction The effect of high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

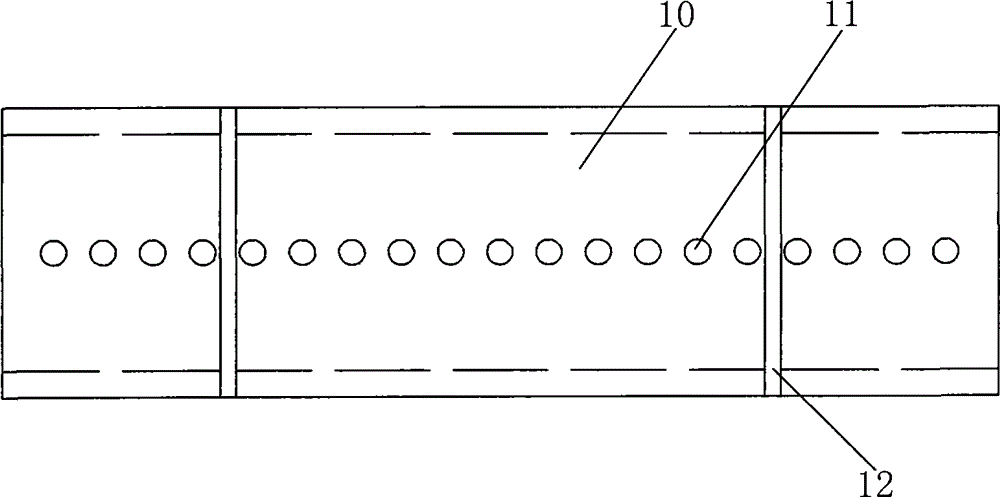

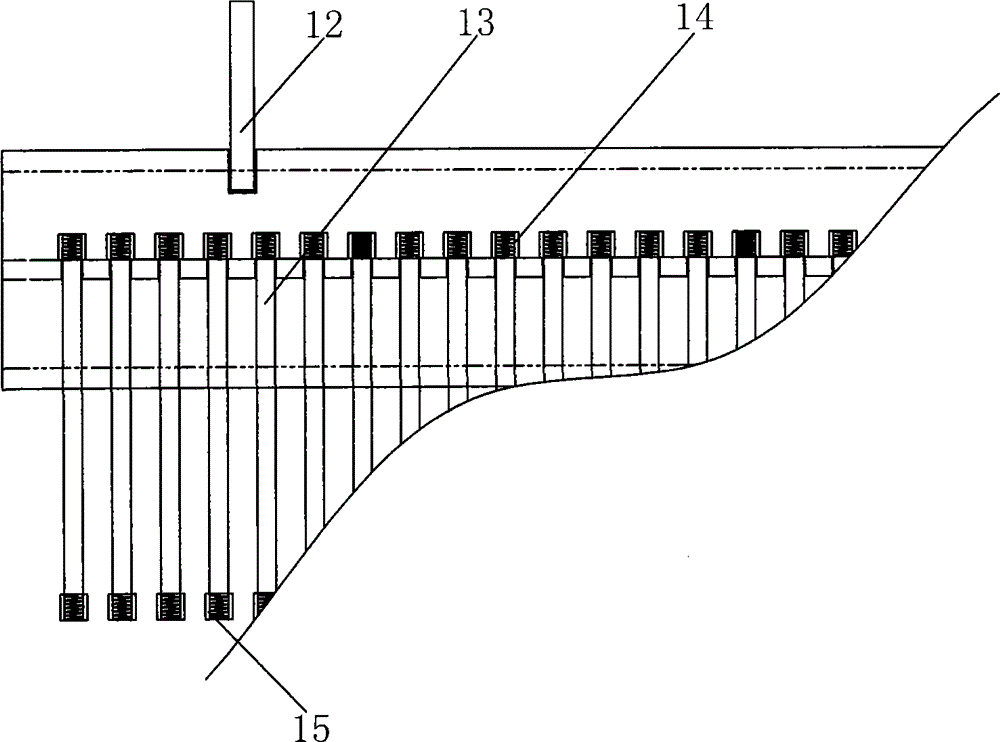

[0015] Such as figure 1 and figure 2 As shown, the vertical steel bar binding hanger has a load-bearing body 10 of a large cross-section I-shaped steel, and a single row of steel bar hoisting holes 11 is provided on the load-bearing body according to the hoisting positions of the vertical steel bars, and each hoisting hole is equipped with a A set of rebar set fixtures. The steel bar suit fixing part comprises the tool bar 13 that vertically passes through in the hoisting hole, the top of the tool bar has a connector, and the lower end of the tool bar is threadedly connected with a steel bar connecting sleeve 15 . The connector is a nut 14 that is sleeved and connected to the top of the tool bar and has a diameter greater than that of the hoisting hole. Two lifting points 12 are symmetrically welded on the bearing body, and the lifting points are lifting lugs welded to the bearing body at both ends of the round steel after the U-shape is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com