Wedge type mechanism capable of automatic regulating brake gap

A brake clearance and automatic adjustment technology, applied in the direction of the slack adjuster, etc., can solve the problems of reduced market value, large brake noise, thermal recession, etc., to improve safety and reliability, avoid brake deviation, and reduce the size and the effect of small mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

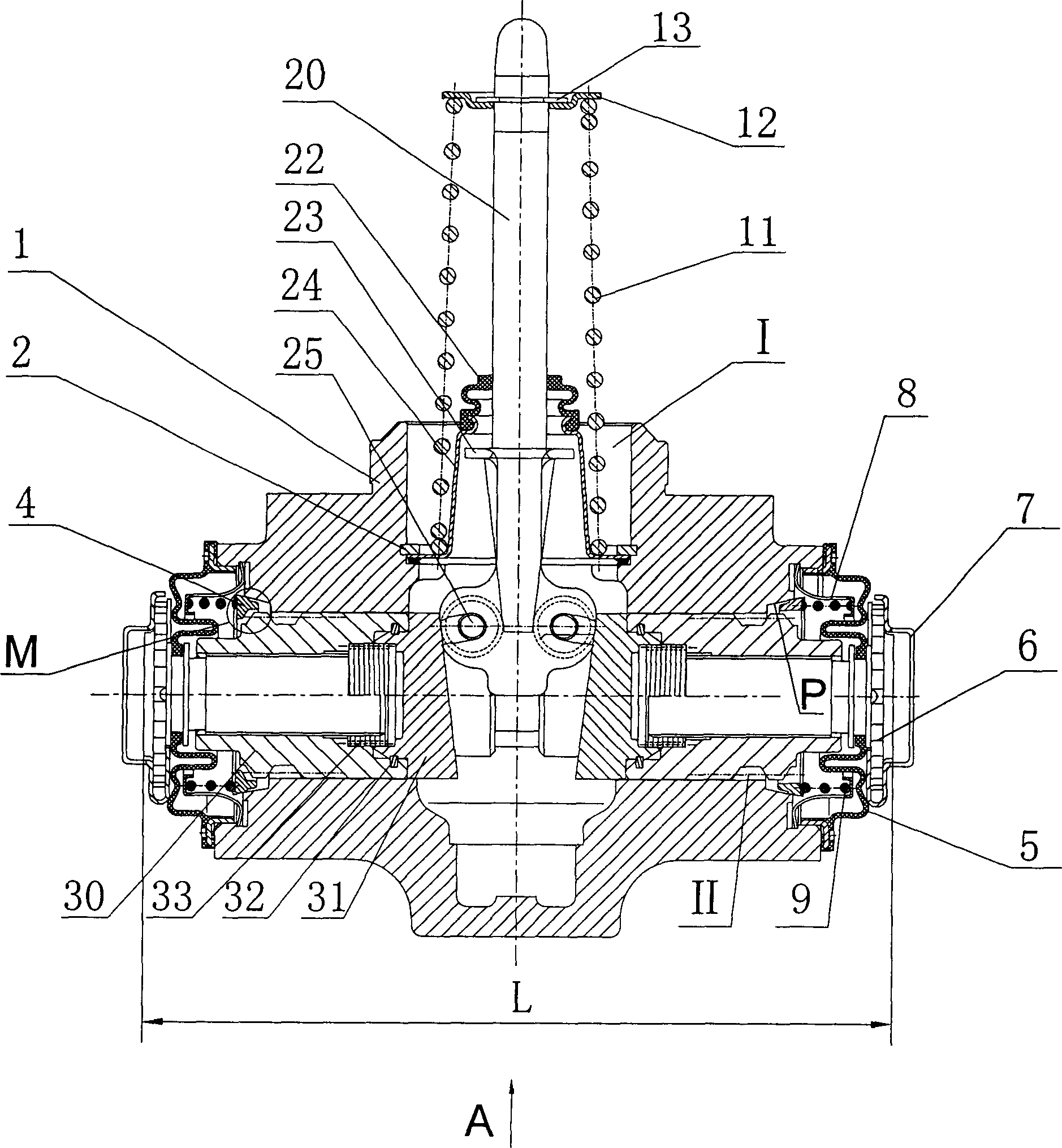

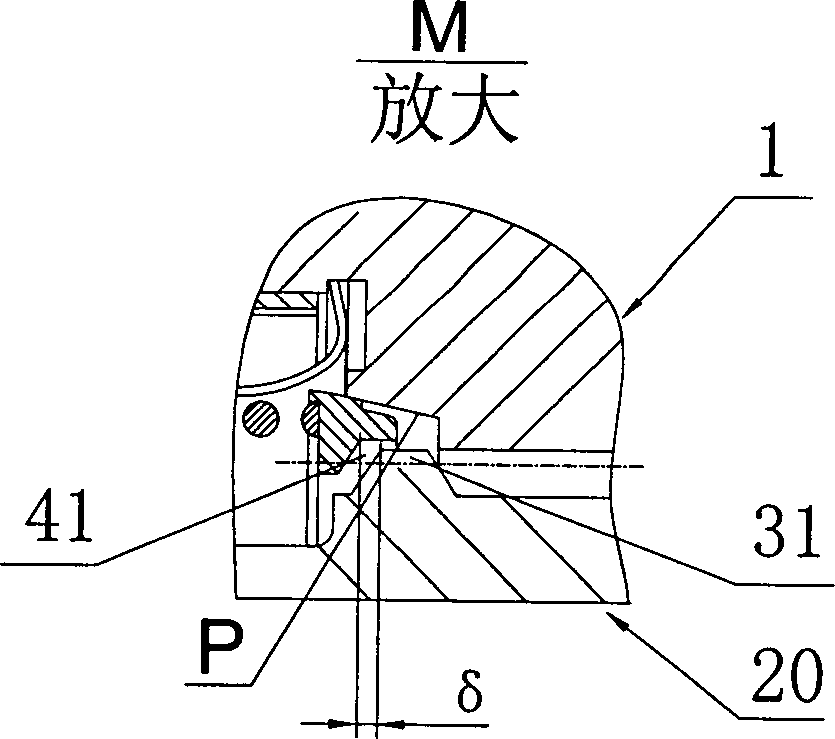

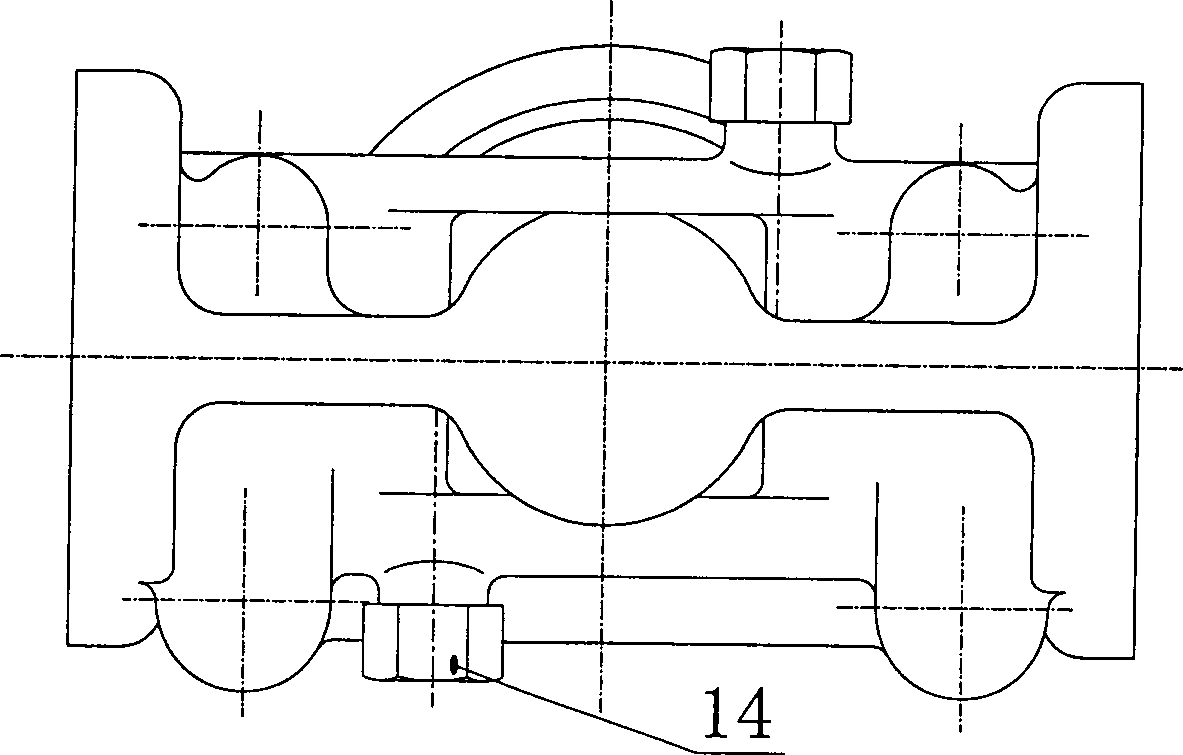

[0020] control figure 1 , the symmetrical center of the housing 1 is provided with a vertical hole I, the end cap is connected in the hole I, and the symmetrical sides of the hole I are respectively provided with a horizontal through hole II communicating with it, and the outer end of each through hole II is provided with Conical surface P, a driving ring 40 is placed inside the conical surface P, and a shield 8 connected to the housing 1 is placed on the outer end side of the driving ring 40, and one end of the driving ring spring 9 abuts against one end of the inner end surface of the shield II Against the outer end surface of the drive ring 40, the drive ring 4 is pressed against the conical surface P on the through hole II.

[0021] The piston 30 is slidably connected in the through hole II, and its rear end is hinged with the roller push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com