Method of using pre-applied underfill encapsulant

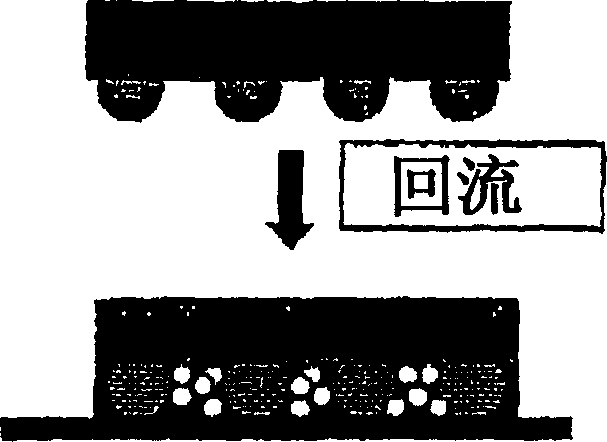

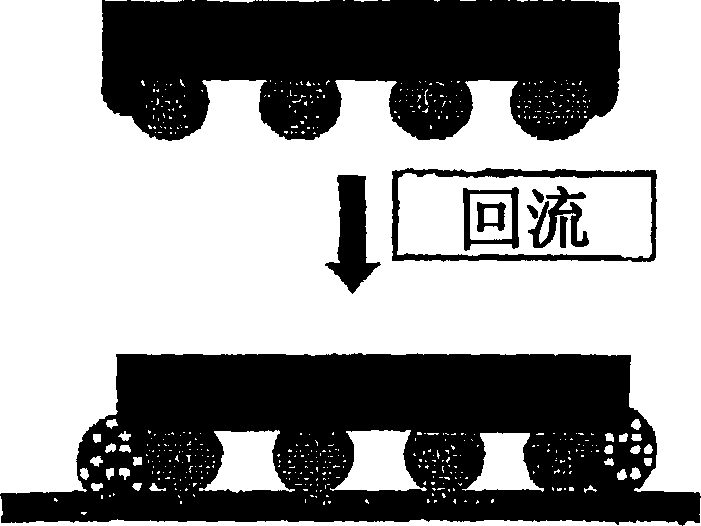

一种底层填料、密封剂的技术,应用在涂加非金属保护层、用电元件组装印刷电路、可持续制造/加工等方向,能够解决底层填料材料困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. Thermoplastic and thermosetting underfill compositions were prepared as follows (amounts of all components are expressed in weight percent). The mixture of solvent and resin was added to a mixing vessel equipped with a propeller stirrer. Then add the expandable filler and mix for 5-10 minutes until homogenization is achieved. Surfactant is then added to help the vacuum remove air bubbles. The mixture was degassed for 5 minutes at a pressure of >28 Hg in a vacuum chamber. The formulations of the obtained thermoplastic underfills are shown in Table 1.

[0034] Material

Formulation A

Formulation B

PKHS-30PMA 1

19.8

20.0

Byk-A-500 2

0.05

0.05

098DUX120

0.2

0.1

[0035] 1 Phenoxy resin solution in PGMEA from Inchem.

[0036] 2 Degassing additive from BYK Chemie.

[0037] Formulation A was tested for various properties, including drop impact resistance, and the results of tho...

Embodiment 2

[0042] Example 2. Preparation of a pressure sensitive pre-applied fluxing underfill formulation having the components listed in Table 3.

[0043] components

[0044] * Bisphenol A type / Bisphenol F type epoxy resin mixture

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com