Center post of annular field coil in global Tokamak magnet

A tokamak and central column technology, applied in the direction of plasma, greenhouse gas reduction, nuclear reactor, etc., can solve the problems of adding cooling system, complex process, low conductor filling rate, etc., to increase the conductive area, improve safety, The effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

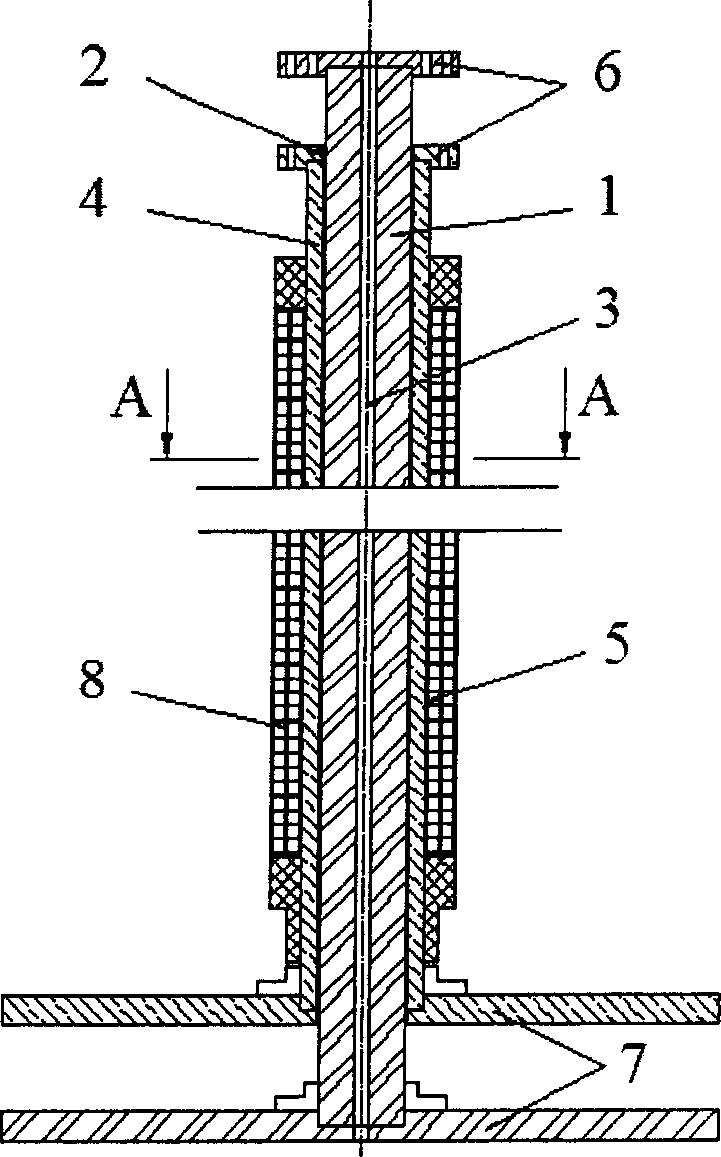

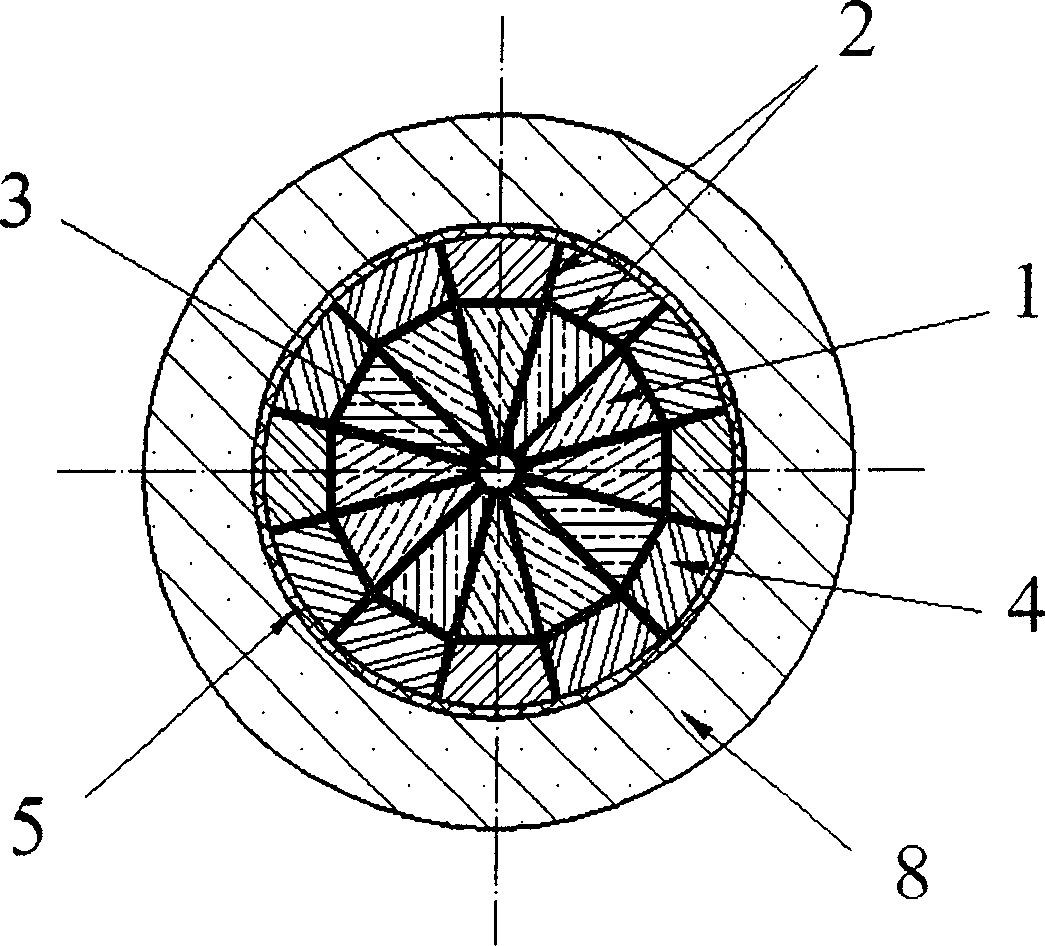

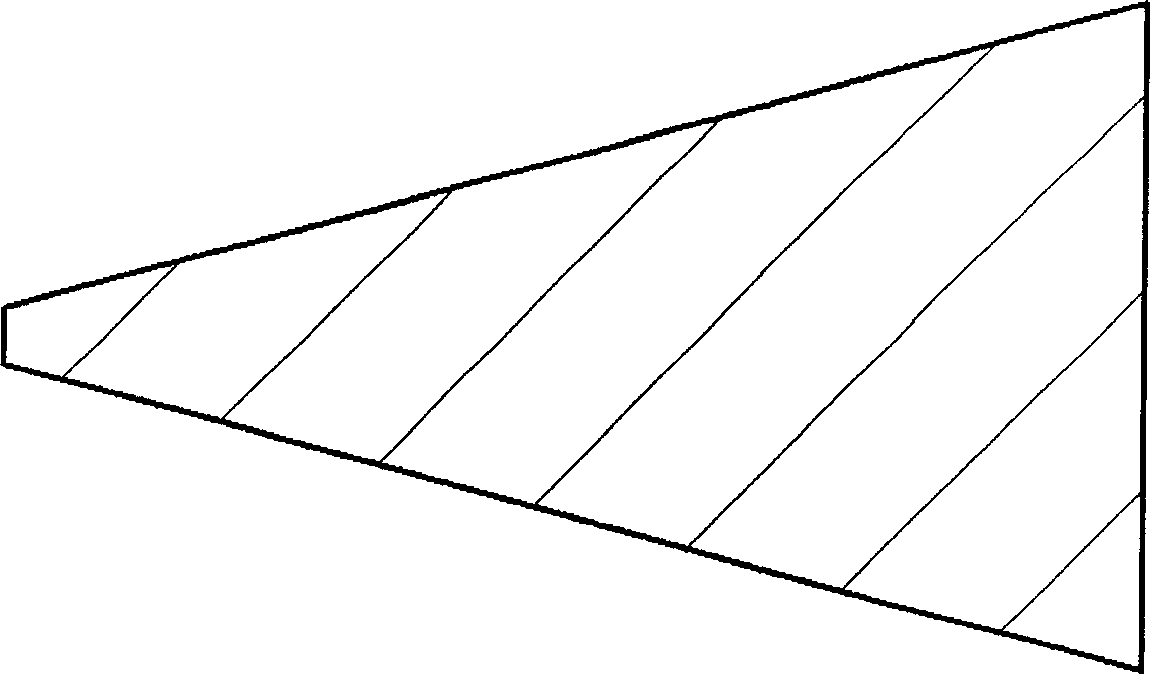

[0018] figure 1 It is a structural diagram of the present invention, in which the central column of the present invention is composed of inner and outer layers of special-shaped conductors, and each of the inner and outer layers of special-shaped conductors has 12 pieces, which are evenly distributed and arranged along the circumferential direction. The upper and lower ends of each shaped conductor are welded with connecting terminals 6 and 7 distributed along the circumference and perpendicular to the axis of the central column. The inner conductor 1 of the central column is made of oxygen-free copper material through extrusion molding; the epoxy glass laminate 2 has a thickness of 1 mm; the central cooling hole 3 is automatically formed when the inner conductor 1 is arranged along the circumferential direction; the central column The outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com