Process for weaving fabrics and shaggy fabrics

A technique for raising fabrics and weaving fabrics, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of hard fabrics, too expensive, and difficult to produce beautiful patterns on the back of fabrics, etc., and achieve excellent pile strength and reduced load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

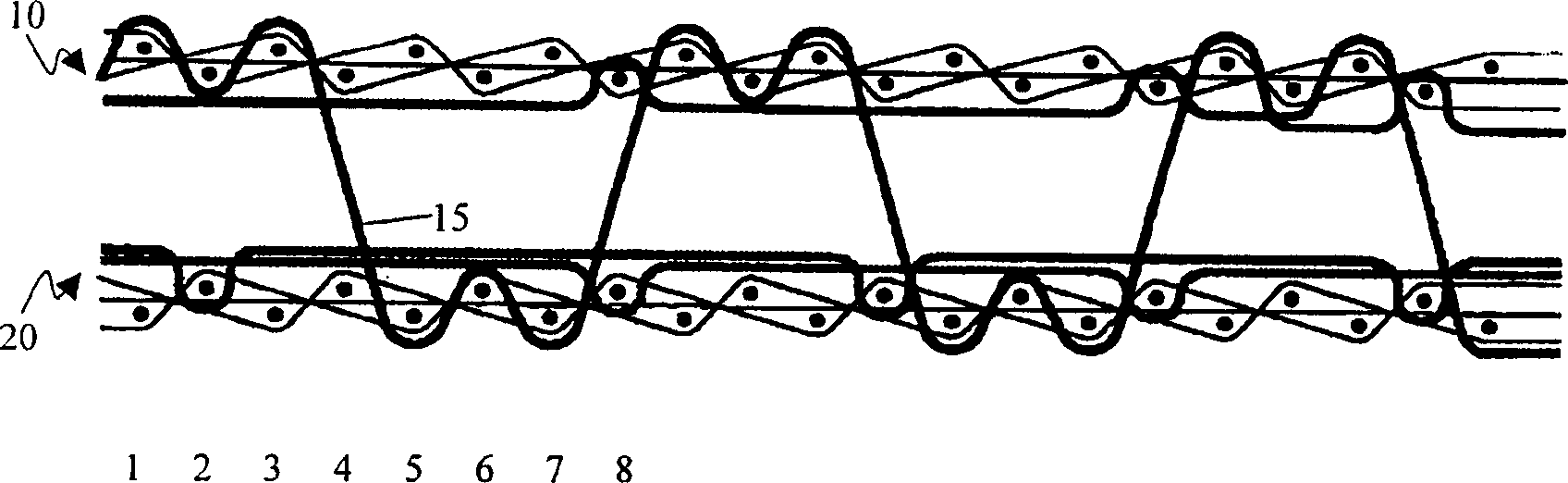

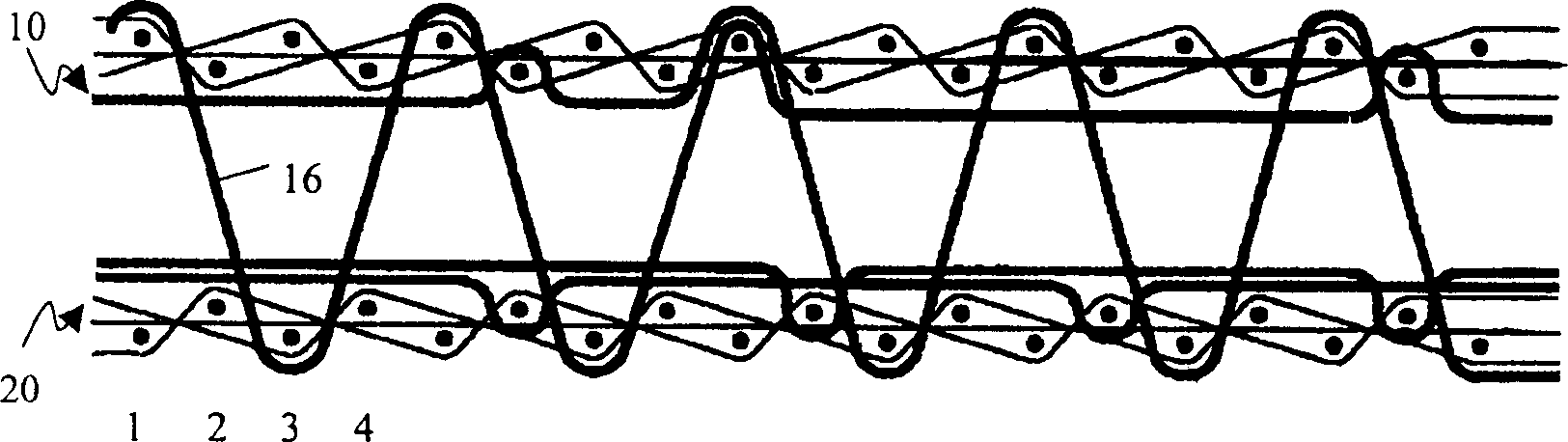

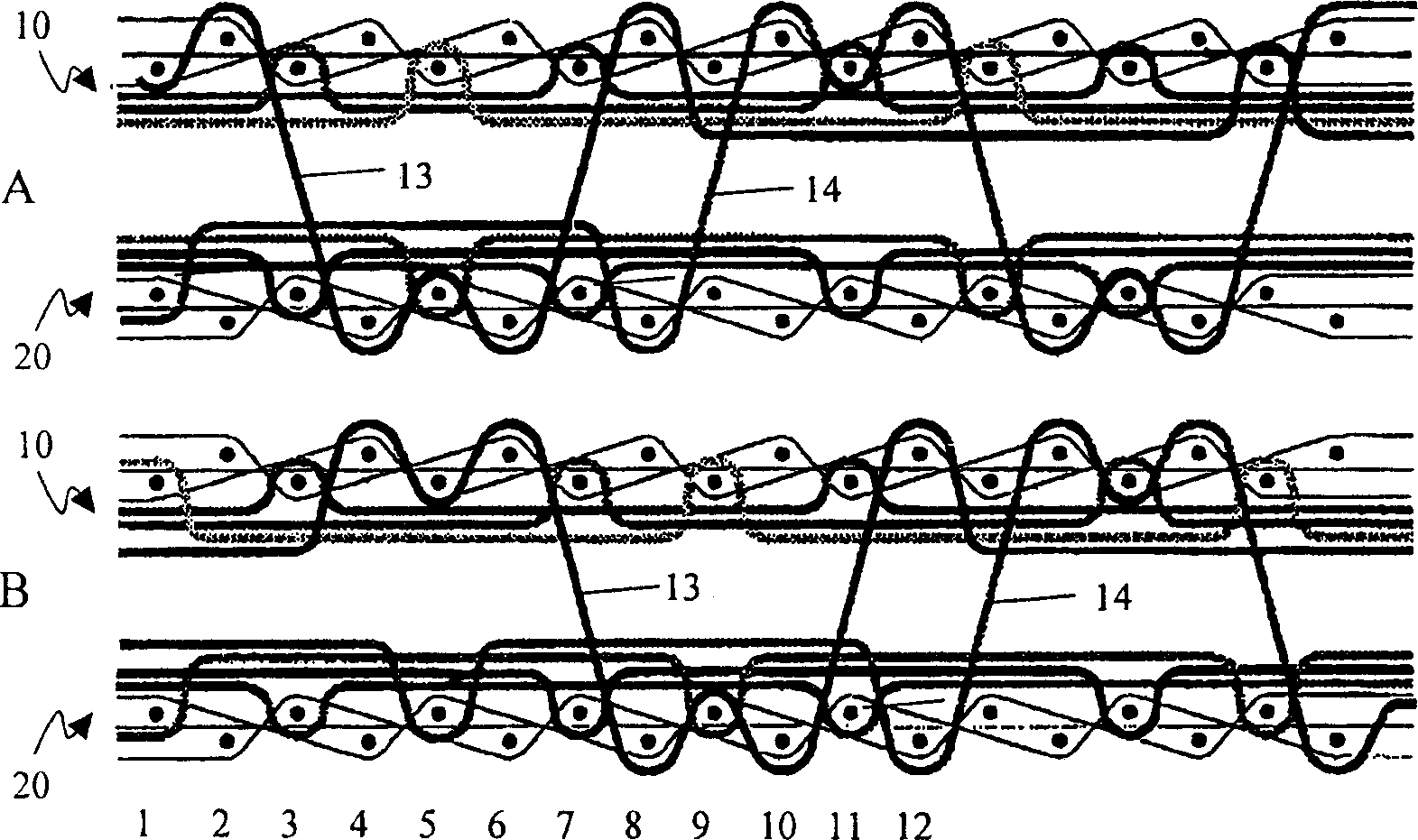

[0060] In double jacquard weaving, pile warp threads with different characteristics such as colour, thickness, effect etc. are used which are woven into the fabric according to a specific weave. Each type of pile warp is given in each warp system. As mentioned above, a warp system refers to a group of warp yarns comprising tensioning warp yarns, binding warp yarns and / or pile warp yarns, which warp yarn systems extend side by side in the weft direction. With the Jacquard device, each pile warp thread can be placed in the correct position of the shed to achieve the desired weave, and the reed beats up the weft as the weft thread is introduced. Since the fabric is cut pile in a traditional 1 / 2V weave, the different types of yarns are presented once in each warp system, and all pile warp systems are constructed identically.

[0061] In pile weaving, however, other weaves are known, the pile not having such a dense weave over multiple weft threads. A W texture is a good example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com