LED light source module

A technology of LED light source and power cord, applied in the field of transformation of LED light source module, can solve the problems of not considering dustproof, waterproof, poor reliability of use, short service life, etc., achieve long service life, avoid rainwater infiltration, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

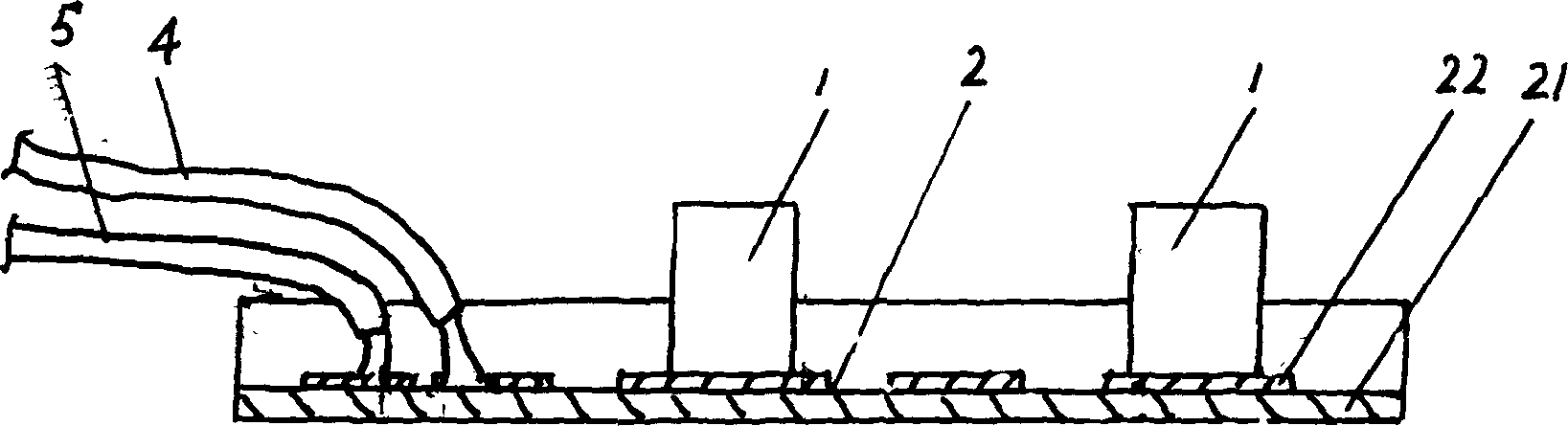

[0011] The structure diagram of the present invention is as figure 1 As shown, it includes several LEDs (1), circuit boards (2), wherein the circuit board (2) includes a bottom plate (21) and a wiring layer (22), pins and power lines (3) of several LEDs (1) (4) Welded on the wiring layer (22) of the circuit board (2), several LEDs (1) are connected in series and / or in parallel on the power line (3) (4), and the upper end surface of the wiring layer (22) A waterproof insulating layer (4) is provided to cover the entire surface of the LED (1) and the welding points of the LED (1) and the power line (3) (4).

[0012] The cross-sectional shape of the circuit board (2) is regular or irregular polygonal or curved. The above LEDs (1) include several rows and columns distributed on the wiring layer (22) of the circuit board (2) or include several rings distributed on the wiring layer (22) of the circuit board (2). In this embodiment, the cross-sectional shape of the circuit board (2...

Embodiment 2

[0014] The structure of the present invention is the same as that of Embodiment 1, the difference is that the cross-sectional shape of the circuit board (2) is a regular hexagon, and 6 LEDs (1) are circularly distributed on the wiring layer of the circuit board (2) (22) on.

Embodiment 3

[0016] The structure of the present invention is the same as that of Embodiment 1, except that the cross-sectional shape of the circuit board (2) is circular, and 15 LEDs (1) are divided into two circular rings and are evenly distributed on the wiring layer of the circuit board (2) (22) on. There are 6 LEDs (1) distributed in the inner ring, and 9 LEDs (1) distributed in the outer ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com