Liquid jet polishing method

A liquid and polishing liquid technology, applied in spray guns, explosion generating devices, abrasives, etc., can solve problems such as difficult to achieve numerical control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

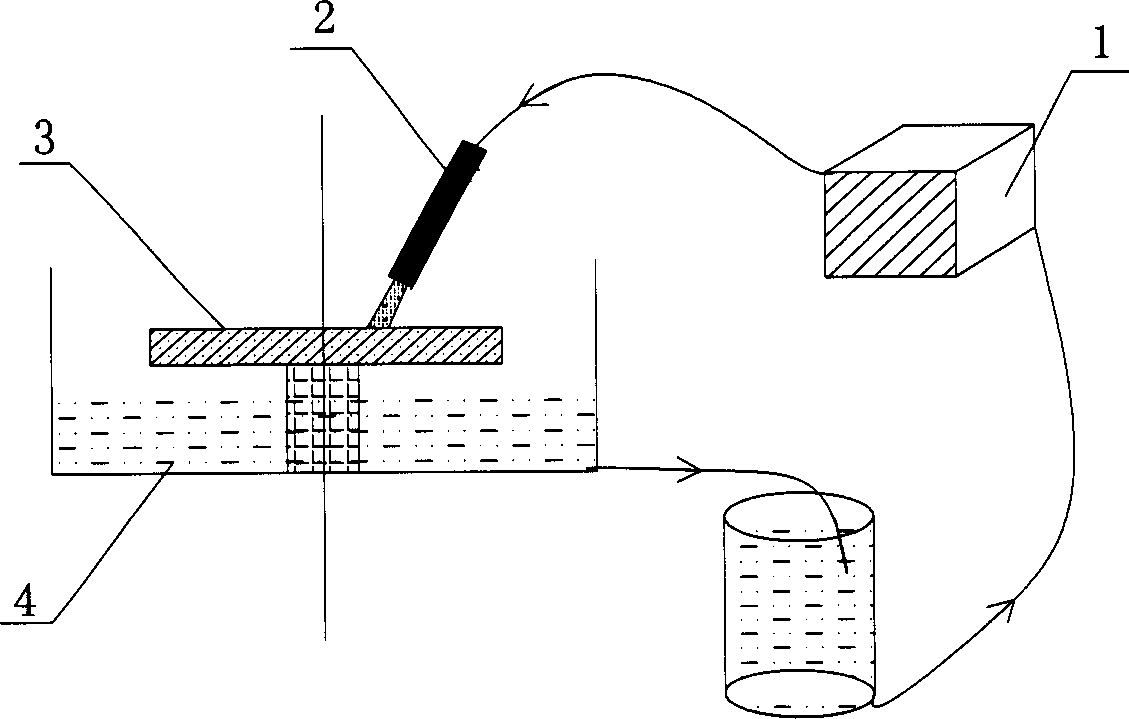

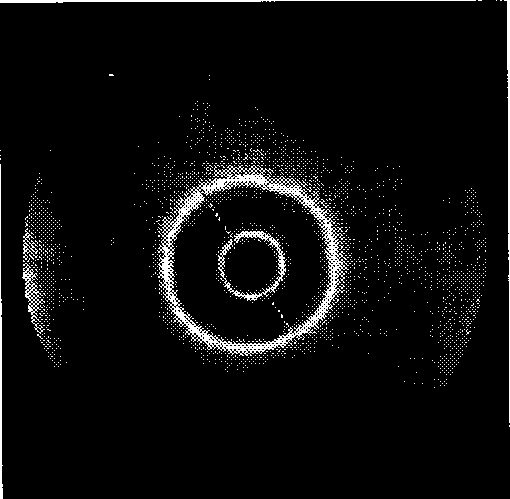

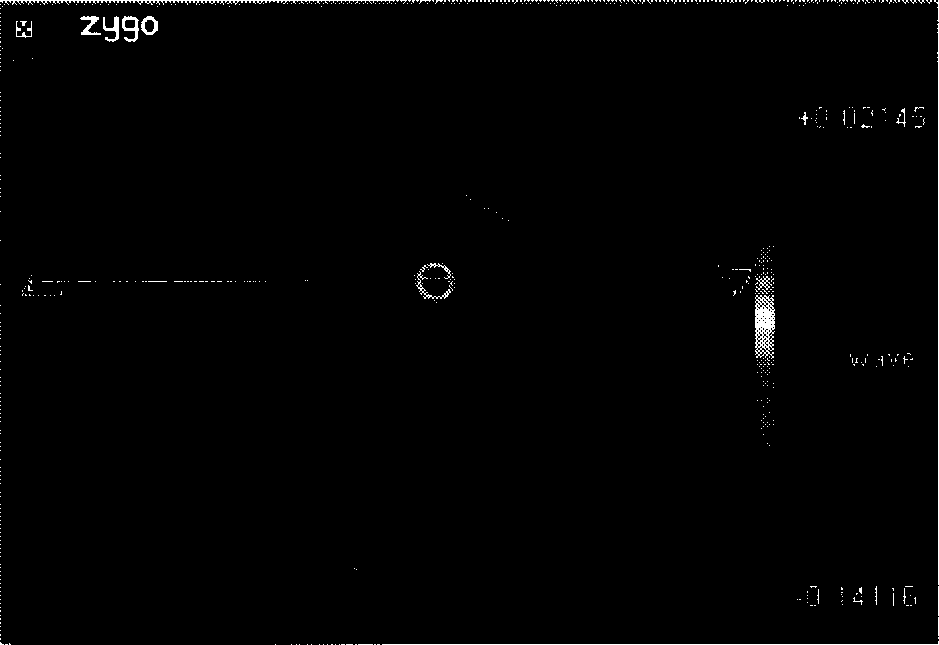

[0027] Embodiment one: see attached image 3 and 4 As shown, a method of liquid jet polishing, the polishing liquid mixed with abrasive particles is accelerated by a high-pressure pump, ejected from the nozzle, shot at the surface of the workpiece, collides with the workpiece, and polishes the surface of the workpiece. The diameter of the tube is 1.2 mm. The workpiece rotates around the normal line of the center of the processing area. The axis of the nozzle tube is perpendicular to the tangent plane of the center of the processing area. The distance between the intersection point of the extension line of the tube axis and the surface of the workpiece and the center of the processing area is about 1 mm. , the workpiece is rotated at an angular velocity ω=168 rpm, the working distance is 7 mm, the working pressure is 4.5 bar, the action time is 8 minutes, and the polishing liquid is sprayed continuously.

[0028] See attached image 3 Shown is a schematic diagram of the distr...

Embodiment 2

[0029] Embodiment two: see attached Figure 5 As shown, a method of liquid jet polishing, the polishing liquid mixed with abrasive particles is accelerated by a high-pressure pump, ejected from the nozzle, shot at the surface of the workpiece, collides with the workpiece, and polishes the surface of the workpiece. The axis of the tube is perpendicular to the cut surface of the center of the processing area, the polishing liquid is sprayed in gaps, the nozzle rotates one circle relative to the center of the processing area, and the polishing liquid is sprayed 4 times.

Embodiment 3

[0030] Embodiment 3: A method for liquid jet polishing. The polishing liquid mixed with abrasive particles is accelerated by a high-pressure pump, ejected from the nozzle, and shot at the surface of the workpiece, colliding with the workpiece, and polishing the surface of the workpiece. The angle between the pipe axis of the nozzle and the tangent plane at the center of the processing area is 60°, and the polishing liquid is sprayed continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com