Method for polishing computer-controlled gadget

A computer and small tool technology, applied in the direction of manufacturing tools, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems that affect the quality of the surface shape, do not have the ability to remove materials, etc., and achieve the effect of eliminating high-frequency errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

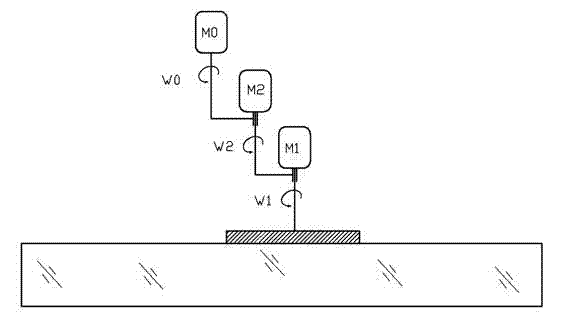

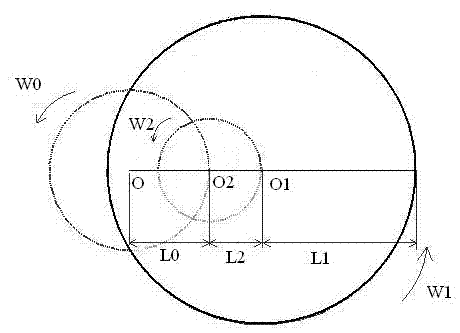

[0022] Embodiment one: see attached figure 1 And attached figure 2 , small tools are polished by computer control, the polishing mold adopts three-rotor movement, the polishing mold is centered on O1 and rotates at angular velocity W1 under the control of motor M1, and revolves around O2 at angular velocity W2 under the control of motor M2. The planetary motion mechanism composed of motors M1 and M2 revolves around O at an angular velocity W0 under the control of motor M0. The speed of the three motors and the movement of rotating shaft O are controlled by the computer, thereby realizing CNC polishing.

Embodiment 2

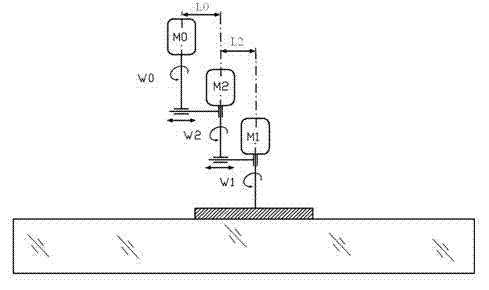

[0023] Embodiment two: see attached image 3 , computer-controlled small tool polishing, revolution speed of planetary motion mechanism, revolution speed of polishing mold, rotation speed of polishing mold, distance L0 between the axis line of motor M0 and the axis line of motor M2, the axis line of motor M1 and the axis of motor M2 The distance L2 between the heart lines is continuously adjustable.

[0024] Computer-controlled small tool polishing, the radius of the polishing mold is 13mm, L2=4.5mm, L0=12mm, W1= 20rpm, W2=140rpm, W0=1.75rpm, according to the actual process conditions, the workpiece is fixed, and the polyurethane circular polishing mold works Pressure 250g, ambient temperature 20 degrees Celsius, cerium oxide polishing powder with a particle size of 1~3μm, according to figure 1 The movement method is to continuously polish a K9 plane for 15 minutes at a fixed point.

[0025] See attached Figure 4 And attached Figure 5 Shown is a schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com