Electro-optical device, image printing apparatus, and method of manufacturing electro-optical device

An electro-optical device and electro-optic technology, applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, optics, etc., can solve the problem of poor light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]

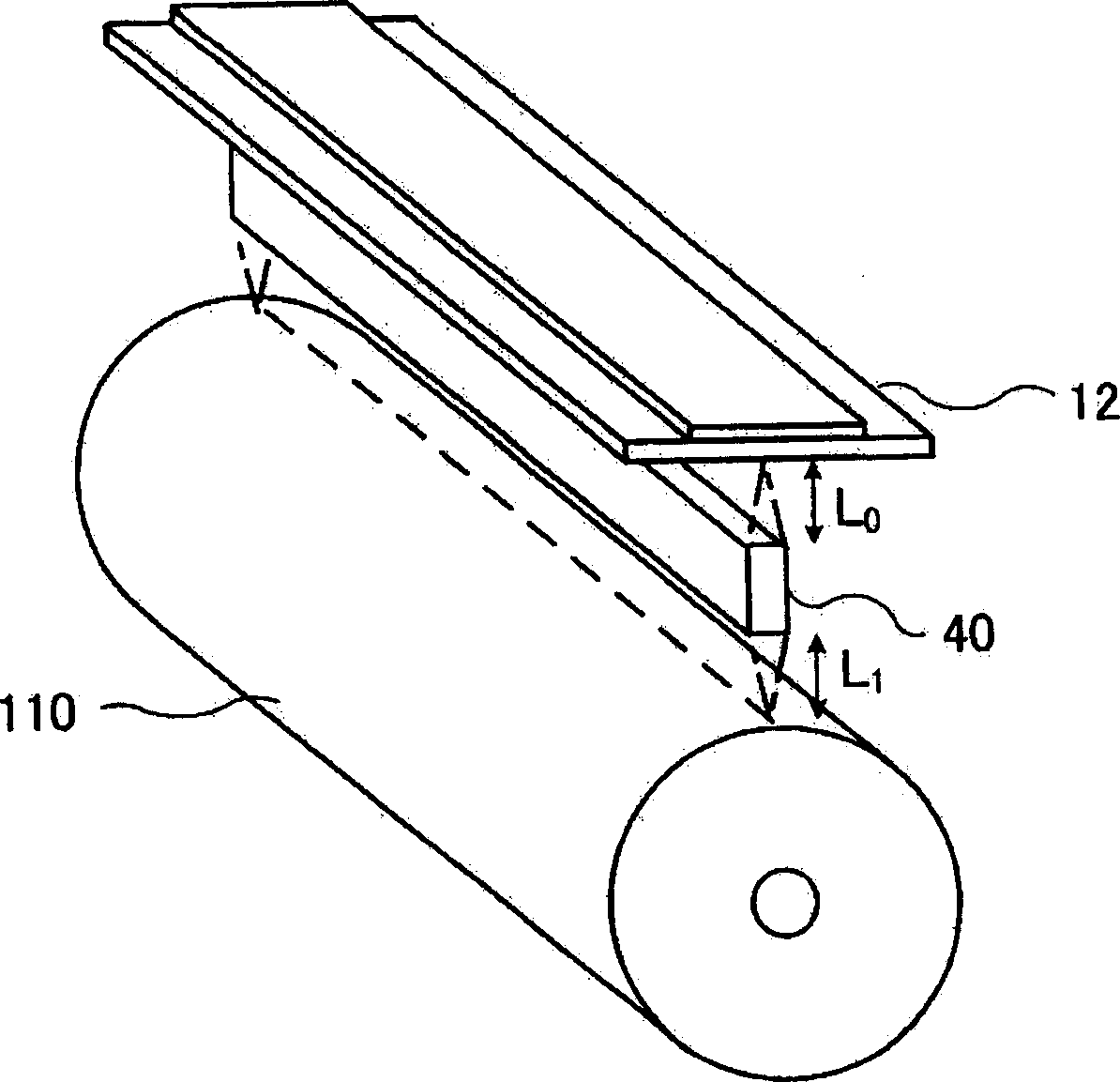

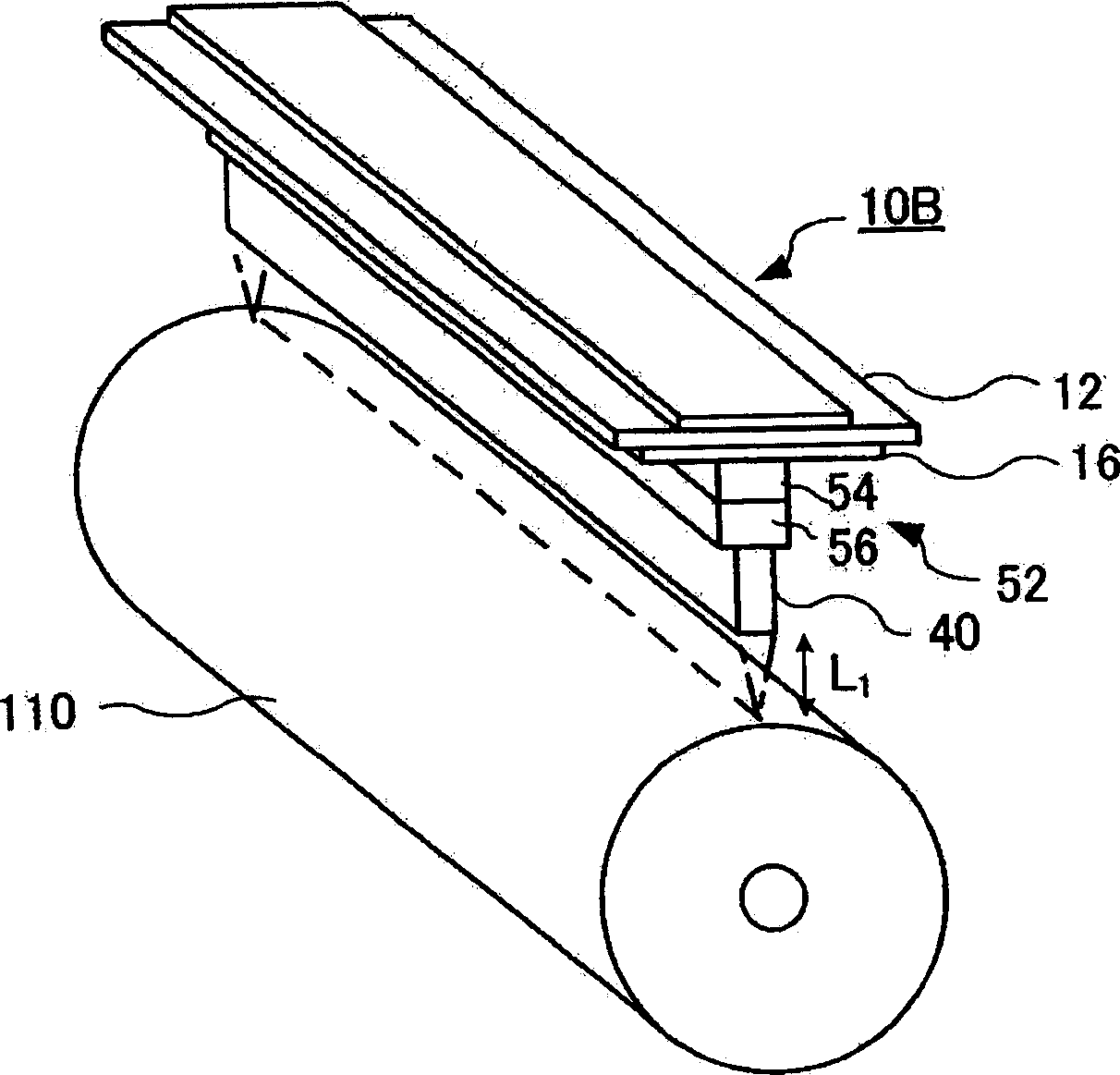

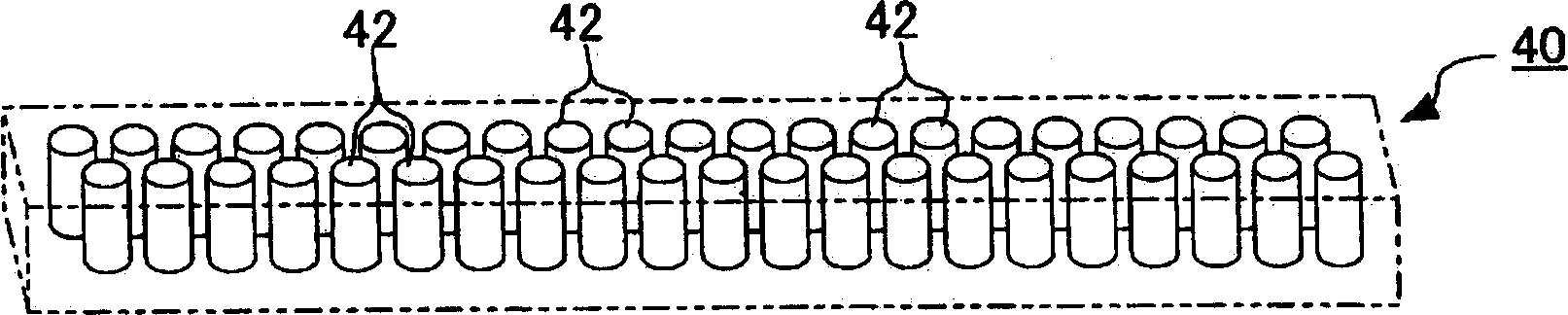

[0056] figure 2 It is a schematic perspective view showing an electro-optical device 10B according to an embodiment of the present invention. The illustrated electro-optical device 10B is used as an image carrier (such as figure 2 A linear optical head for writing a latent image in the shown photosensitive drum 110). The electro-optical device 10B includes a light-emitting panel (electro-optical panel) 12 in which a plurality of organic EL elements (electro-optical elements) are arranged on the same plane, and a focusing lens array 40 superimposed on the light-emitting panel 12 . Between the light-emitting panel 12 and the focusing lens array 40 is interposed a light-transmissive spacer 52 made of glass or plastic, and the spacer 52 has a plurality of light-transmissive spacers 56 and 58 laminated. The focusing lens array 40 is disposed between the light emitting panel 12 on which the EL element array is provided and the photosensitive drum 110 . The light from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com