Pressure adjustment mechanism of pressure cooker

A technology of pressure regulating mechanism and pressure cooker, which is applied in the direction of pressure cooker, etc. It can solve the problems of interference with pressure inspection effect, poor pressure regulation effect, inaccurate pressure inspection, etc., and achieve the effect of eliminating explosion phenomenon, wide application range and high pressure regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

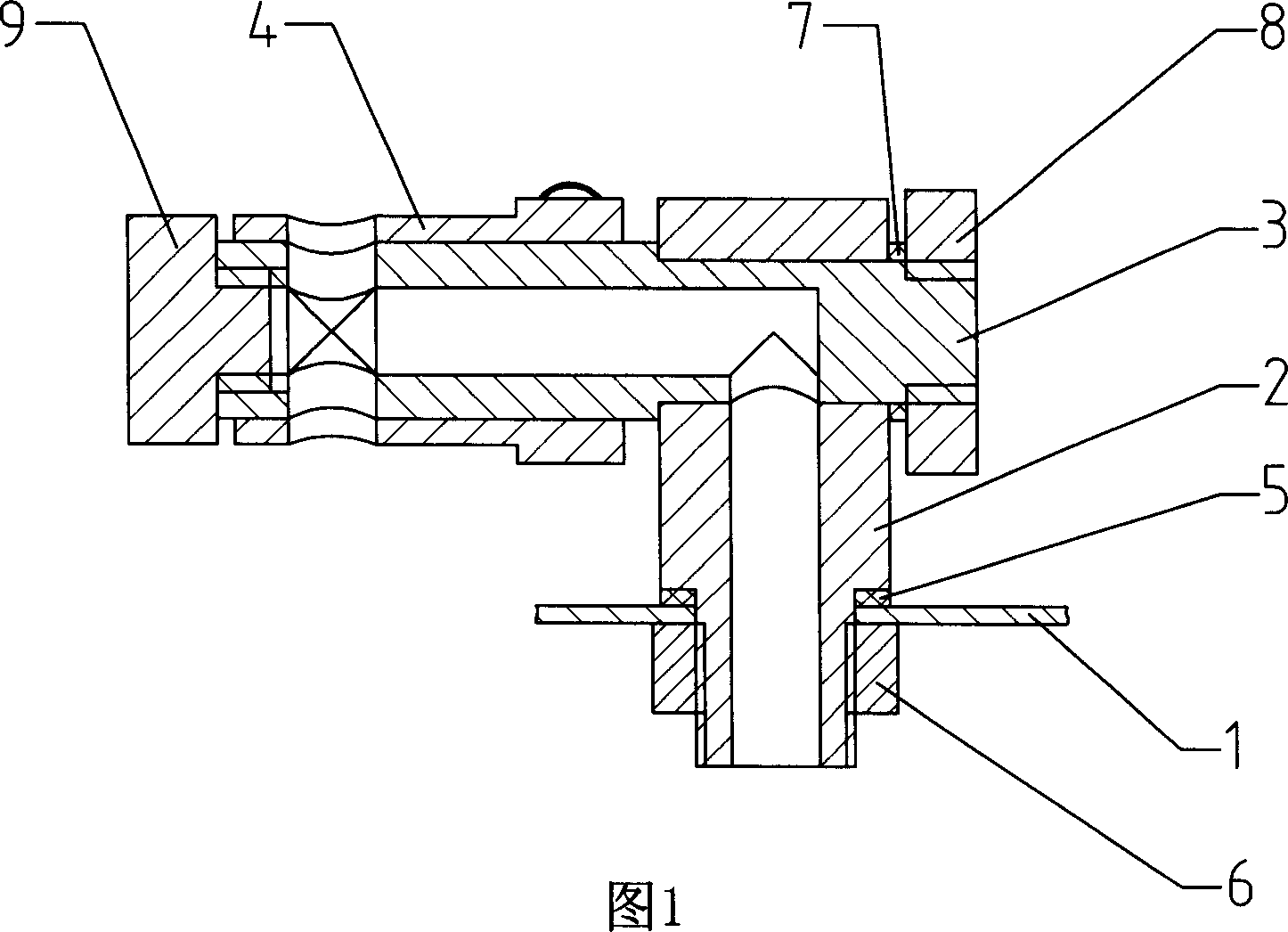

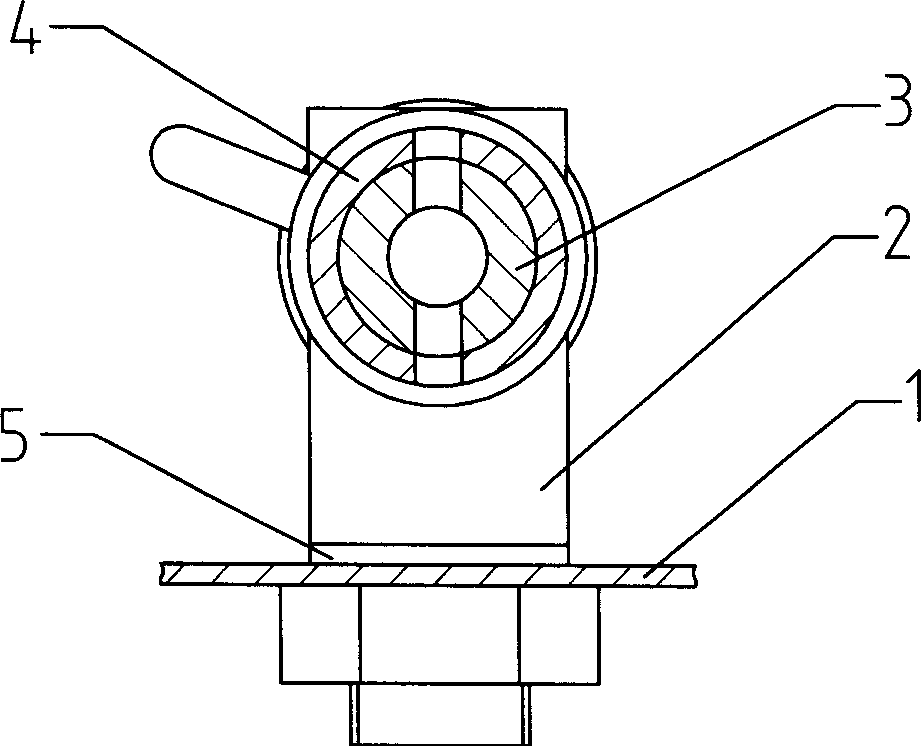

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] According to Figure 1 and figure 2 As shown, in the pressure regulating mechanism for the pressure cooker involved in the present invention, the exhaust shaft support 2 is fixedly installed on the pressure cooker cover 1 through the gasket 5 and the nut 6, and a cavity and a lateral through hole that can communicate with the cavity are provided on it. , the cavity can guide the active leakage of the gas in the pot. The exhaust shaft 3 is connected to the lateral through hole of the exhaust shaft bracket 2 through one end of the shaft body. Have an exhaust cavity and at least two axially symmetrical and communicated lateral through holes with the exhaust cavity. Two lateral through holes are preferably used. In addition, the exhaust cavity on the exhaust shaft 3 can be connected with the exhaust shaft. The cavities on the bracket 2 communicate. One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com