Cryostat assembly

A technology for cryostats and components, used in refrigeration components, instruments, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

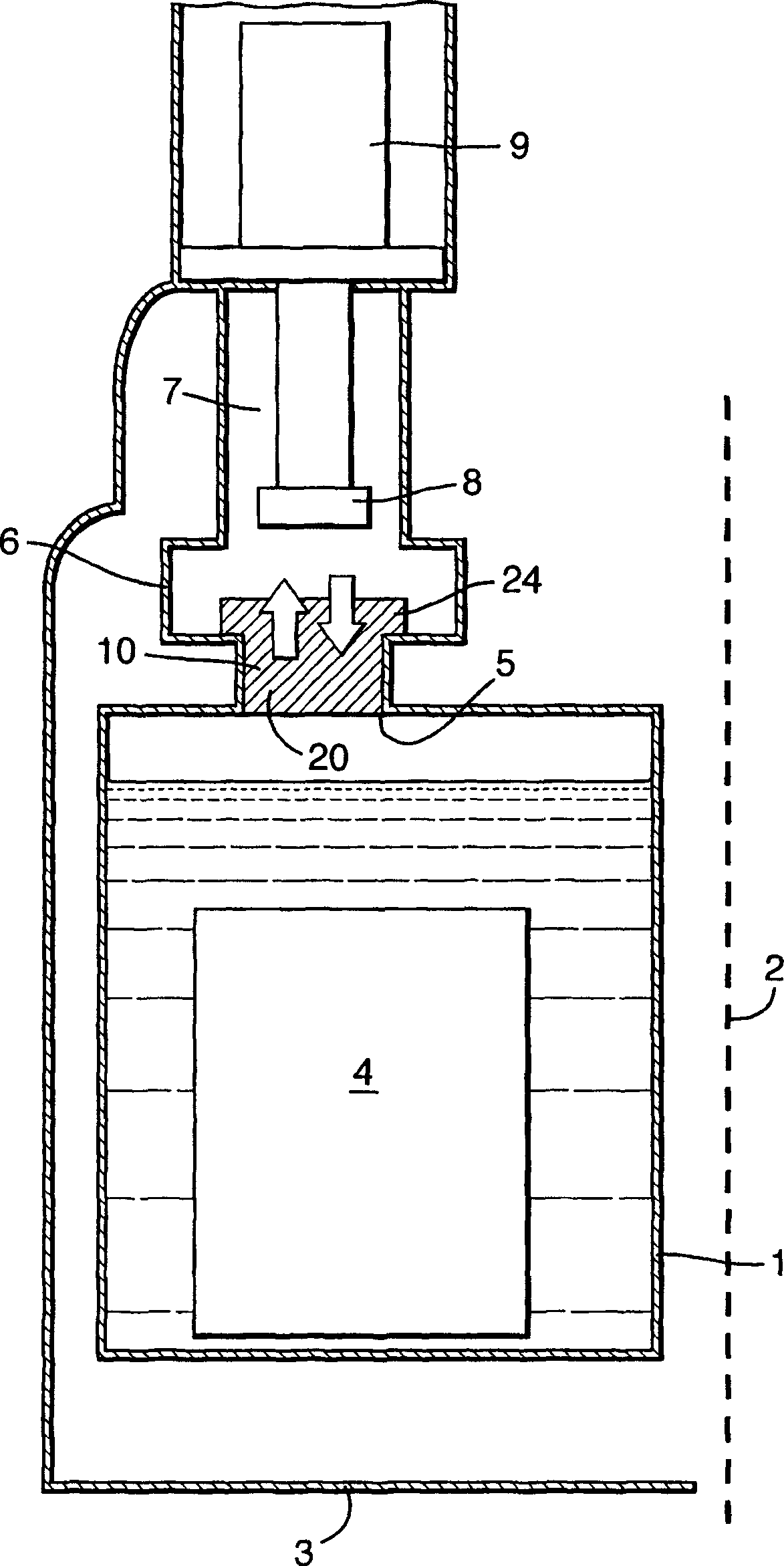

[0019] image 3 The components of a cryostat assembly for NMR are shown schematically. The assembly includes an annular liquid helium container 1 arranged around an axis 2 and defining a bore (not shown). In fact, the container 1 is surrounded by multiple heat shielding devices, and there may be other coolant containers, but for simplicity, only a single 50K heat shielding device 3 is shown in the figure.

[0020] There is a ring-shaped superconducting magnet 4 in the container 1 and it also surrounds the axis 2.

[0021] The upper wall of the container 1 has an aperture 5. The aperture 5 is connected to a cavity 6 or a turret (turret) 7, wherein the cavity 6 has an outwardly extending tube, and the second stage 8 of a two-stage pulse tube refrigerator (PTR) 9 is arranged in the turret 7 . Typically, a part of the wall of the cavity 6 forms a bellows to limit the propagation of vibrations.

[0022] In use, the heat reaching the container 1 causes the liquid helium to boil, and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com