High water repellency artificial leather and its manufacturing method

A technology of artificial leather and manufacturing method, which is applied in the direction of textiles and papermaking, can solve the problems of non-waterproof, artificial leather not water-repellent, etc., and achieve high water-repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

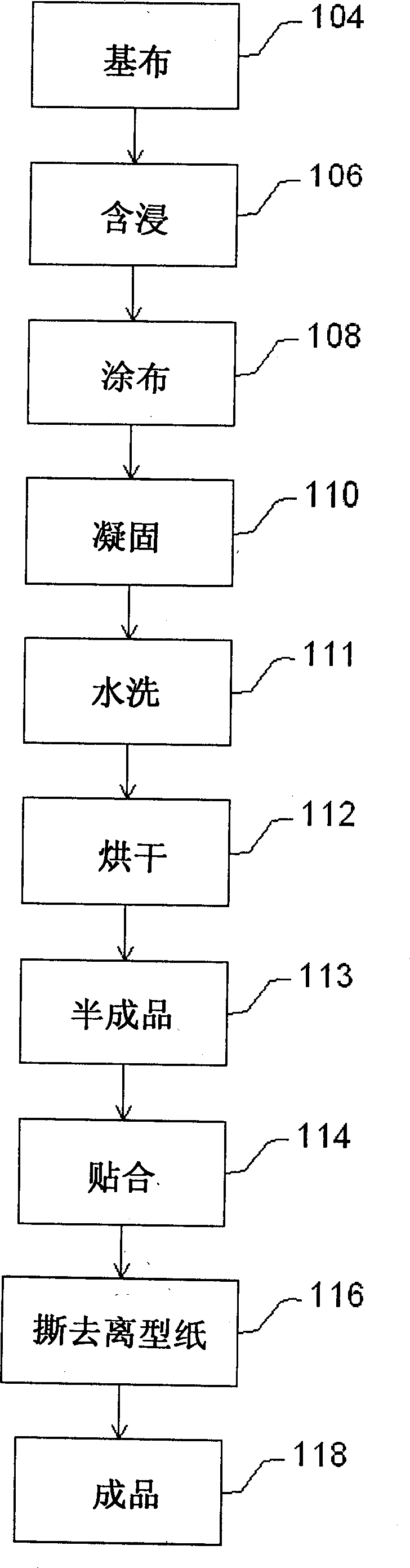

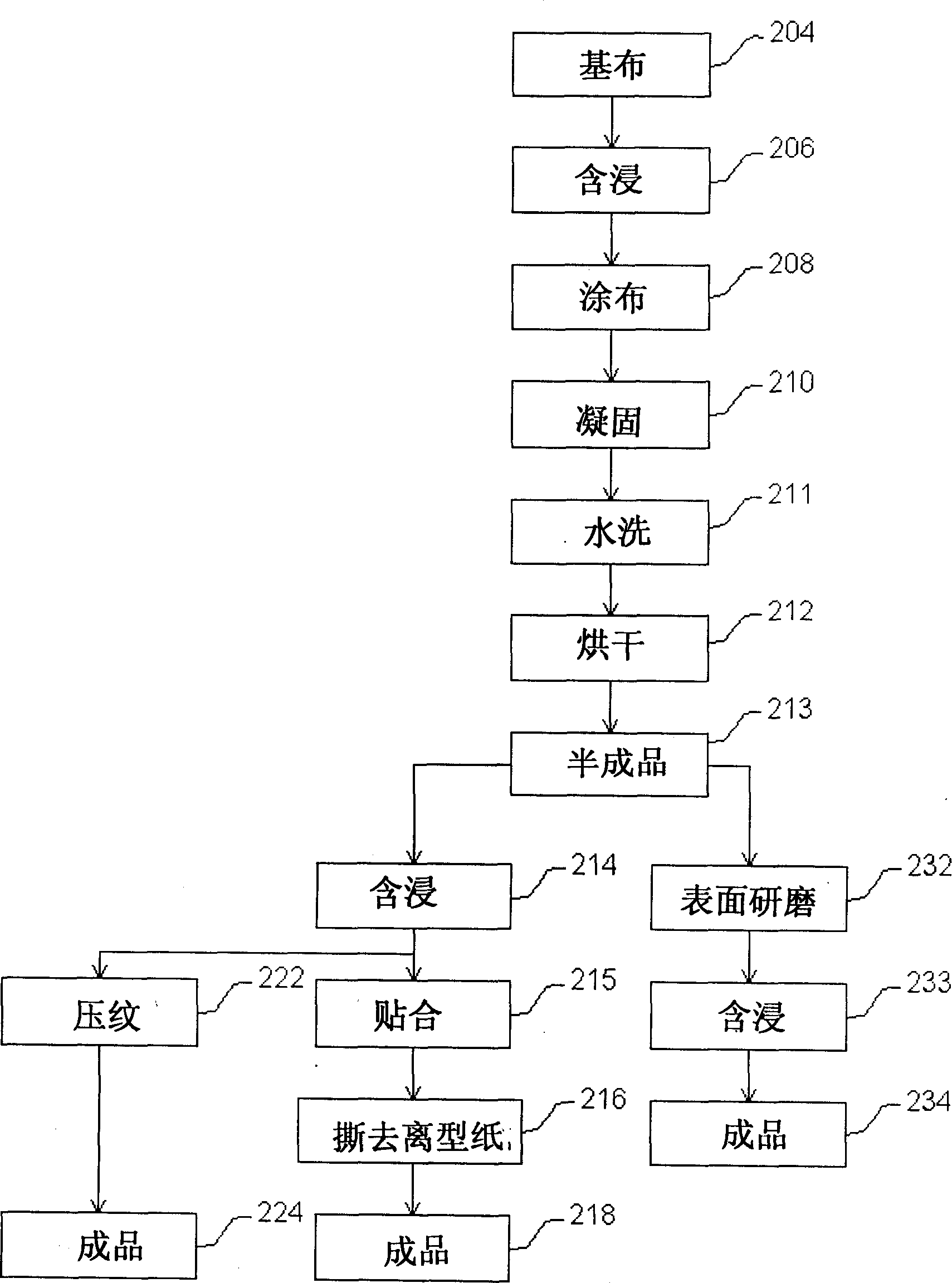

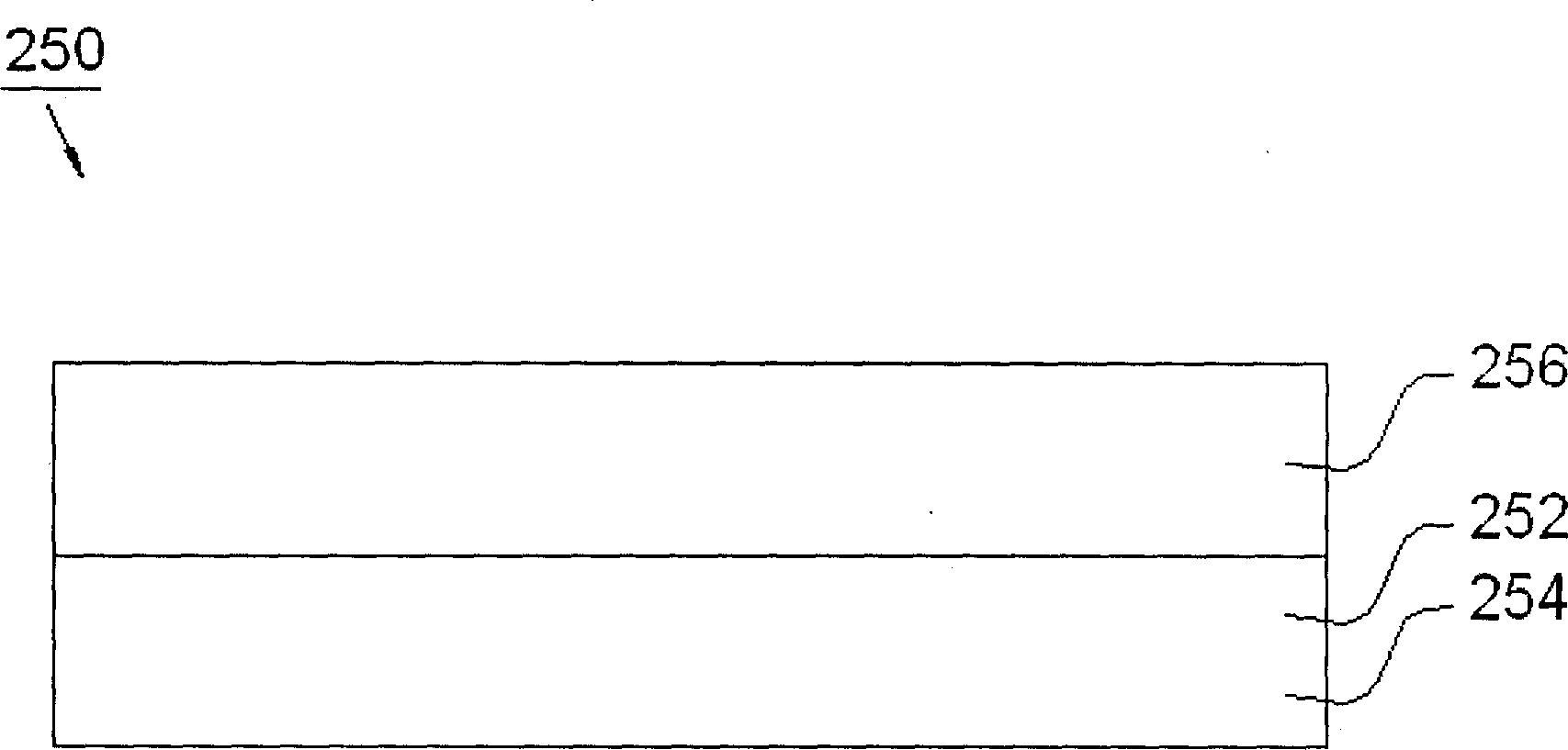

[0047] refer to figure 2 , according to the first embodiment of the present invention, the manufacturing method of highly water-repellent artificial leather mainly includes first and second stages, wherein the first stage is to form a semi-finished artificial leather, and the second stage is to produce a semi-finished artificial leather similar to genuine leather texture to form the finished artificial leather. The first stage includes steps 204 to 213. First, a base cloth 252 is provided (step 204), and the base cloth 252 is impregnated with a water-repellent polyurethane resin composition to form an impregnated layer 254 in the base cloth 252 ( Step 206), coating the base cloth 252 with the polyurethane resin composition with a water-repellent agent to form a coating layer 256 on the base cloth 252 (step 208), and then coating the impregnated layer 254 and Layer 256 is solidified (step 210), washed (step 211) and dried (step 212) to form a water-repellent artificial leathe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com