Motor drive apparatus driving 3-phase brushless motor without using hall sensor

一种马达驱动、三相的技术,应用在电子换向器、转矩脉动控制、电子换向电动机控制等方向,能够解决难以进行马达控制、不能准确检出零交越点、掩蔽期间变短等问题,达到准确检出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

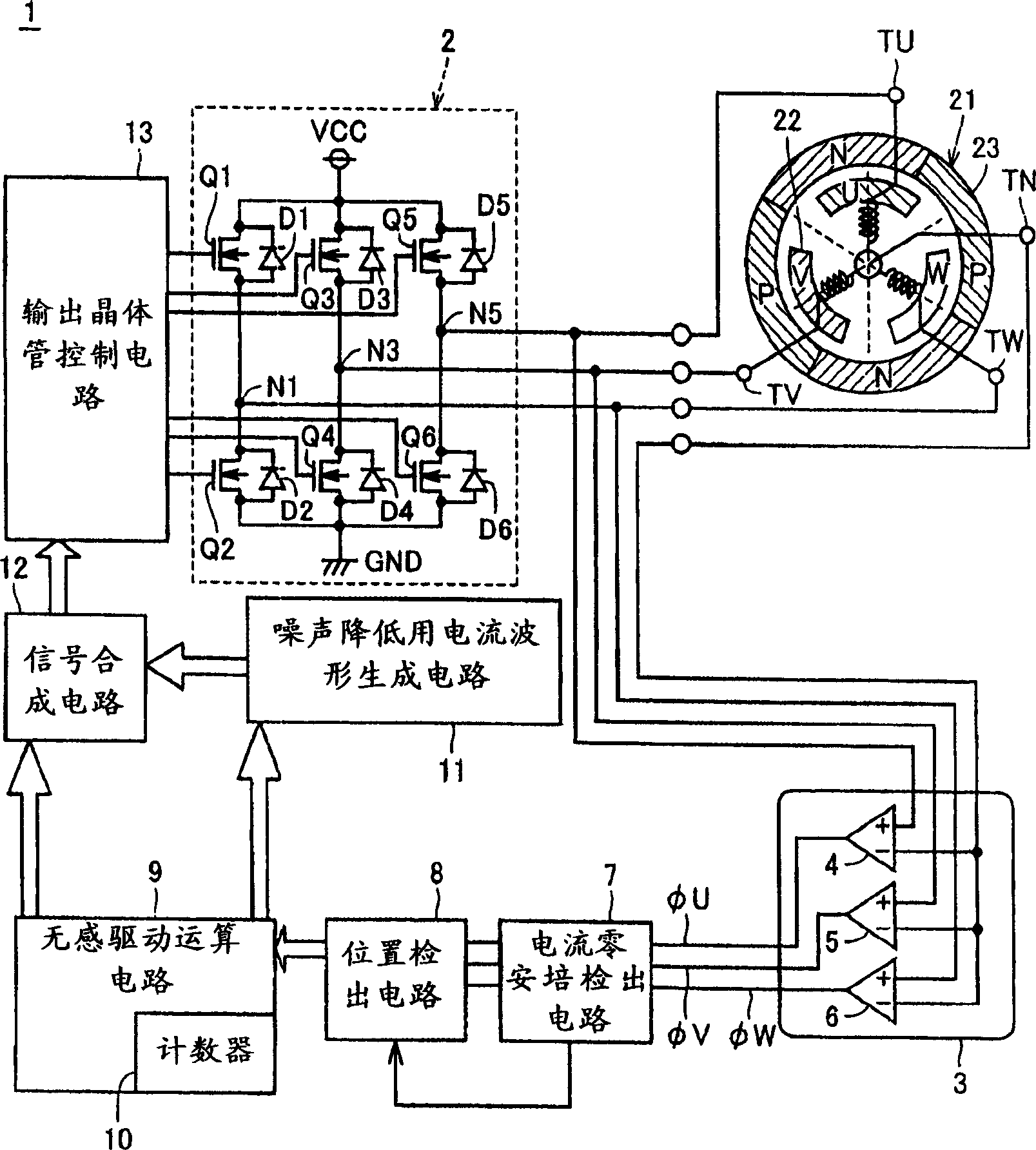

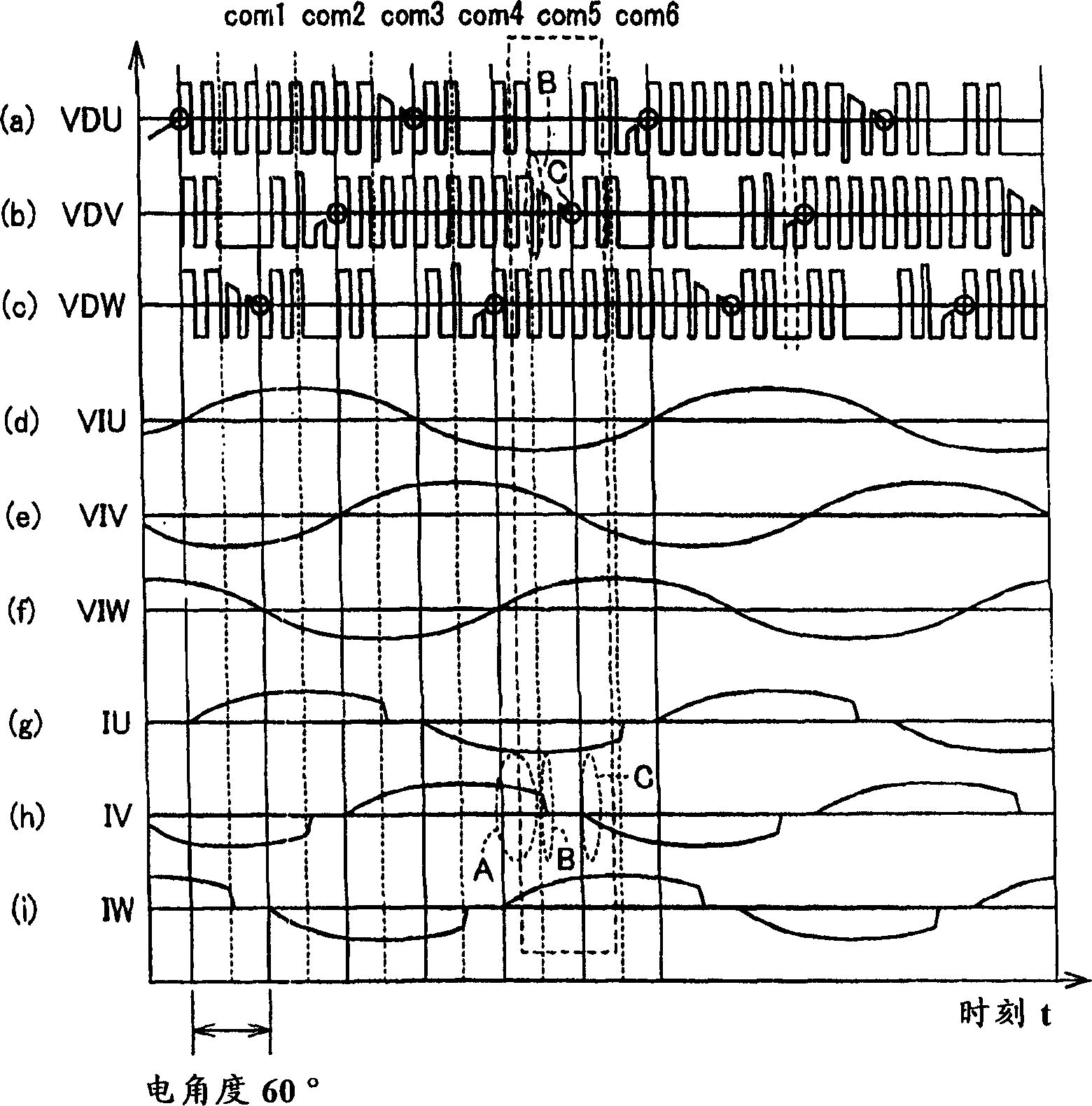

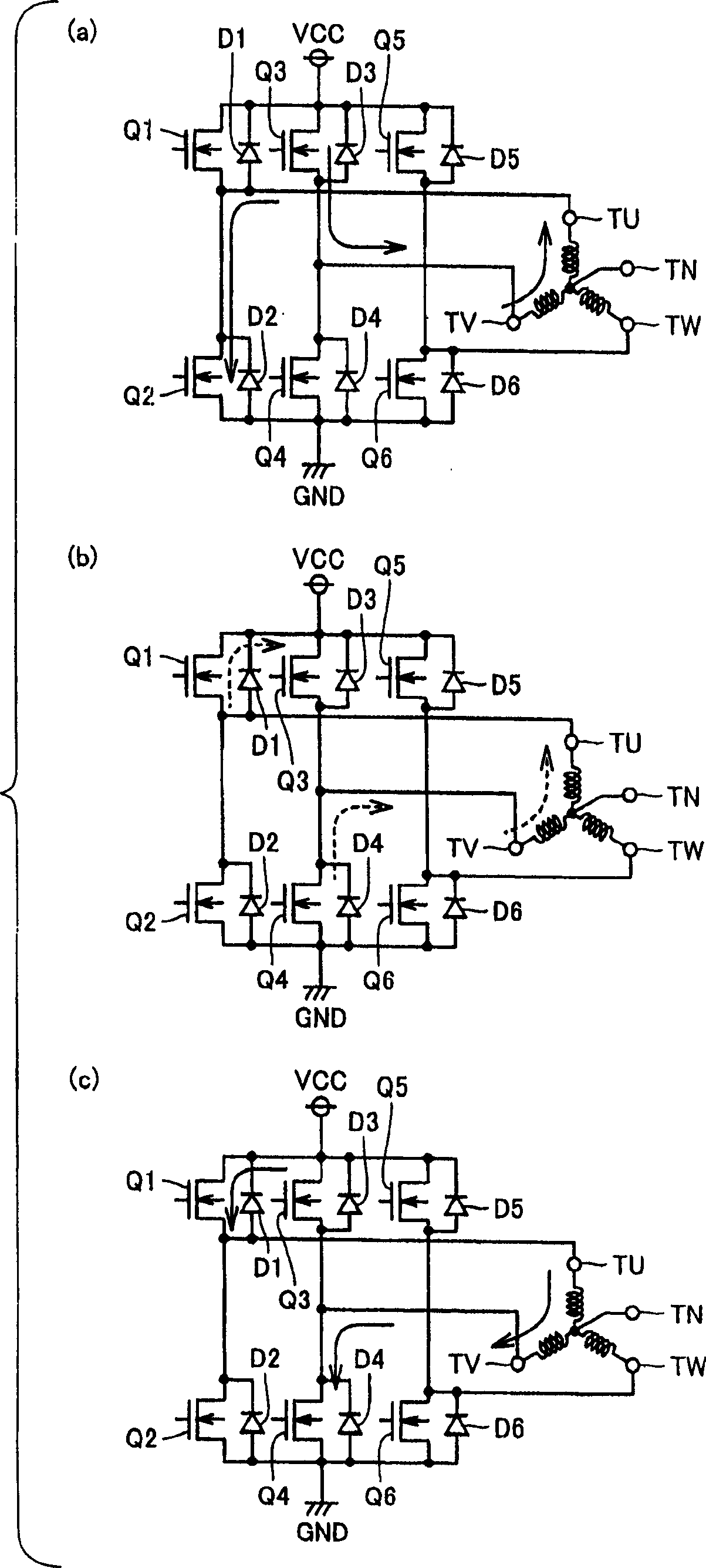

[0016] figure 1 It is a block diagram showing the configuration of a motor drive device 1 according to an embodiment of the present invention. figure 1 Among them, the motor driving device 1 includes: an output circuit 2, a comparison circuit 3, a current zero ampere (0A) detection circuit 7, a position detection circuit 8, a non-inductive drive operation circuit 9, a noise reduction current waveform generation circuit 11, a signal Combining circuit 12 and output transistor control circuit 13, the motor drive device 1 drives a three-phase brushless motor 21 without Hall sensors. The motor driver 1 is formed of one IC.

[0017] The three-phase brushless motor 21 includes a stator 22 and a rotor 23 freely rotatably provided therearound. Stator 22 includes U-phase, V-phase, and W-phase coils that are Y-connected. One ends of the coils of the U-phase, V-phase, and W-phase are respectively connected to the coil terminals TU, TV, and TW of the U-phase, V-phase, and W-phase, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com